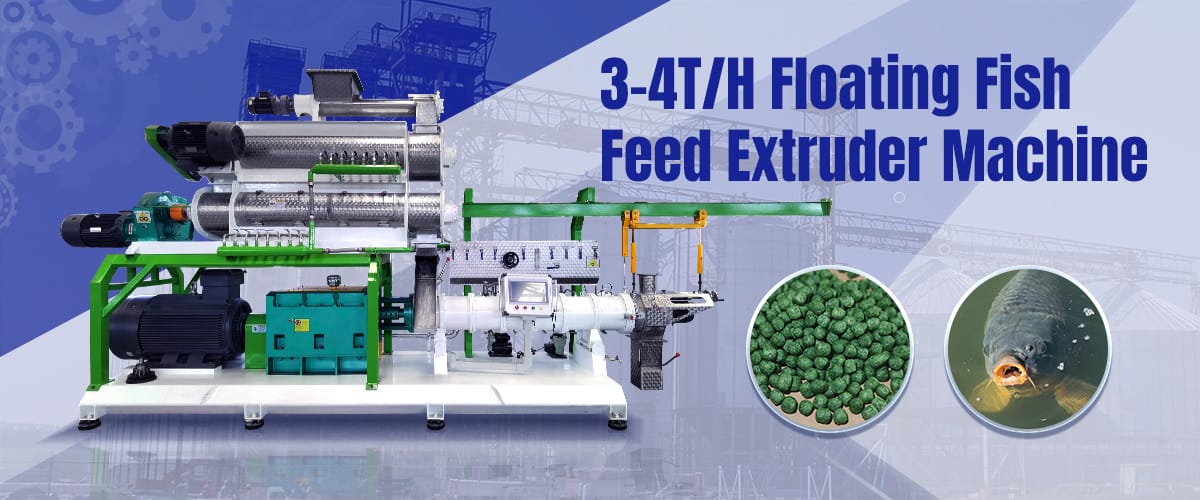

RCPH120*2 floating fish feed extruder machine is the third generation of new twin-screw extruder machine developed by Richi Machinery on the basis of digesting and absorbing foreign advanced technology.

Its power configuration is 90KW, and the output of processing aquatic feed is 3-4 tons per hour. It can meet the current production needs of small and medium-sized aquatic feed processing (floating water feed, slow sinking feed, fast sinking feed, high oil content, wet feed, etc.), various pet foods, and livestock and poultry feed.

In view of the actual situation that the current global aquatic feed processing is dominated by floating feed, the floating fish feed extruder developed by Richi Machinery can not only give full play to the advantages of twin-screw extrusion extruders, but also reduce investment costs as much as possible to process aquatic floating feed .

The 3-4t/h floating fish feed extruder machine price is far lower than that of imported twin-screw extruders, and is only comparable to the price of high-end single-screw extruders. To produce more consistent products and more diversified products, RICHI’s professional twin-screw extruder will bring you greater economic benefits.

Application of floating fish feed extruder machine

- According to the type of fish feed, the fish feed that our fish feed pellet machine can process include betta fish food, trout pellets, catfish pellets, koi food pellets, tropical fish food pellets, arowana food pellets, coppens carp pellets, carp food pellets, bass food pellets, tilapia food pellets, molly fish food pellets, spirulina fish food pellets, glofish food pellets, fish pond food pellets, skretting fish pellets, bluegill food pellets, surgeon food pellets, salmon food pellets, etc.

- According to feed pellet size, our extruder can process micro pellets, 1mm fish feed pellets, 2mm feed pellets, 3mm fish feed pellets, 4mm feed pellets, 6mm feed pellets, etc.

- According to the growth environment of fish, our extruder can process saltwater fish food pellets, aquarium fish food pellets, freshwater fish food pellets, fish farm feed pellets, fish food for ponds, etc.

Features and advantages of fish feed extruder machine

RICHI floating fish feed extruder machine adopts frequency conversion main motor, the transmission system is strong, stable and reliable.

The heating and cooling layer of the barrel is an integral forging structure, the inner sleeve of the barrel and the screw element are made of high wear-resistant alloy steel, and the template uses new materials and scientific hole layout technology.

The fish feed extruder conditioning system adopts extended stainless steel dual-shaft differential speed conditioner, the equipment structure is reasonable, the appearance is beautiful, and its product technical performance has approached or basically reached the level of internationally renowned twin-screw floating fish feed extruder.

But RICHI fish feed extruder price is only 1/3 of the price of imported products, providing low-price, high-performance twin-screw extrusion equipment for global feed and food processing enterprises.

- The adaptability of raw materials is wider, and it can adapt to the processing of high viscosity, low viscosity, high oil content, high moisture or viscous, oily and very wet materials. It can be applied to the processing of various fish feed, shrimp feed, pet feed, livestock and poultry feed.

- There are fewer restrictions on the particle size of raw materials, and it can be adapted to the processing of raw materials with a wide particle size or from fine powder to coarse powder particles and raw materials with particle sizes outside the specific range of single-screw processing.

- The material flow is more uniform in the barrel, which can achieve a more accurate ratio and achieve the actual demand regardless of the addition of steam, water and other auxiliary processes.

- The internal and external quality of the floating fish feed extruder machine is better, which can achieve a very good homogeneous state and make the molecular structure of the material evenly arranged, the surface is smooth during the extrusion molding process, and the product particles have high uniformity and good uniformity.

- The effect of ripening and homogenization is better. Usually, the degree of starch ripening can reach more than 95%, so that the processed aquatic feed can remain stable in water and the nutritional content of the product will not be lost, and it is easy to digest and absorb.

- The output is higher under the same power, and the good mixing performance can homogenize the heat obtained by the material in time, accelerate the ripening degree of the material, reduce the fluctuation of the material temperature, and increase the output of extruded products.

- The floating fish feed extruder machine diversity and adaptability are wider, and it can process granular aquatic feed, high-oil formula, high-moisture, high-cohesive products, and multi-color, sandwich, and special-shaped products.

- The process operation is more convenient, and the spindle speed can be adjusted according to the needs of the processed products. Due to the self-cleaning feature, the cleaning is very convenient, and there is no need to disassemble the equipment after each processing.

- The wearing parts are lighter. It is usually a misconception that the wear of the single screw is less. In fact, due to the stable material transportation and material flow characteristics in the twin-screw extrusion process, the material’s impact on the screw and barrel is determined. The wear of the inner sleeve is smaller than that of the single screw. Although there is one more set than the number of screws, the cost of accessories is still lower than that of the single screw.

- The feed production cost is lower. Due to the good operational stability of the twin-screw model, in the process of feed processing, there is less start-up cost, less waste of water and air, less man-hours, high heat transfer efficiency, high yield, and kWh The output index is high, and the cost of accessories is also low, and its final production cost is still much lower than that of single screw.

Parameters of floating fish feed extruder machine

| NAME | MODEL | POWER(KW) |

|---|---|---|

| Anti-caking bin | PGC900/750 | 1.5 |

| Inverter feeder | WLQ219×1200 | 1.5 |

| DDC-conditioner | DC400*300-244 | 11 |

| Extruder (PLC Controlling System) | RCPH120*2 | 90 |

Other optional models

| Model | DSP200-B |

|---|---|

| Capacity | 3.0-4.0T/H |

| Machine Power | 132KW |

| Feeding Power | 2.2KW |

| Conditioner Power | 5.5KW |

| Cutting Power | 4.0KW |

| Dia. of Screw | Φ195MM |

| EXW Price | 35000-40000 USD |

floating fish feed extruder machine price

3-4T/H floating fish feed extruder price 90,000-110,000USD.

Nowadays, most of the world’s aquatic feed production adopts extrusion processing technology, and more and more feed processing enterprises are gradually replacing traditional pellet mills with extrusion fish feed extruders to produce aquatic feed and other special feeds.

In the aquatic feed market in some countries, because most aquatic feed production enterprises are limited by investment funds, they usually choose low-price single-screw extrusion extruders.

But because of their simple structure, technical level, and low manufacturing level, they can only In aquatic feed processing, it is used to produce low-grade floating feed for freshwater fish, but it is difficult to produce submerged feed and other high-grade aquatic feed products.

Although some imported single-screw models can satisfy the production of high-grade submerged feed products, their prices are too high and there is no good cost performance.

Therefore, when customers choose extrusion equipment, they should not only see that the price of twin-screw extruders is higher than that of single-screw extruders, but should also consider the comprehensive cost performance and the cost of producing per ton of products.

RICHI’s high-quality twin-screw floating fish feed extruder machine has reached a certain advanced level in terms of technical performance and manufacturing level. Although the price is higher than that of ordinary single-screw fish feed extruders, the price is far lower than that of imported single-screw floating feed extruders.

The performance has surpassed the imported single-screw machine and can completely replace the imported twin-screw machine. It can not only meet the needs of high-end aquatic feed in the aquaculture industry, but also achieve high cost performance. It should be the best choice for the current aquatic feed processing industry.

floating fish feed extruder machine projects

Richi Machinery is a relatively professional feed extruder manufacturer in China. All fish feed extruders are designed, produced, assembled and tested in accordance with ISO international quality certification system standards.

The sales network covers more than 130 countries and regions around the world, such as Russia, Indonesia, Iran, Kazakhstan, Zimbabwe, Thailand, Malaysia, India, Ecuador, Bangladesh, etc. Welcome to inquire online about the price, model, drawing, working principle and technical parameters of the fish feed extrusion line.

Precautions for the actual operation of extrusion processing

Maturity degree of starch

During the working process of the floating fish feed extruder machine, the ripening degree of starch is very important, which directly affects the feed digestibility of aquatic organisms and improves the stability of feed products in water.

The ripening degree of starch is affected by the type of starch, crushing particle size and processing conditions during processing. The operation of the conditioning device or fish pellet extruder also has a great influence on the maturity of starch.

- The selection and operation of the fish feed extruder conditioner is very important, especially to control the residence time of the material in the conditioner ( 2min or more) and the quality of added steam. So that the material reaches a material temperature of 90℃ to 95℃ before entering the extrusion cavity.

- And the required moisture is uniform and consistent, and reaches a certain degree of maturity, and the rated mechanical energy is increased during the extrusion process. It can greatly increase the ripening degree of starch.

Floating and sinking materials

The floatability of extruded aquatic feed is directly related to the bulk density of the processed final product. Usually, the bulk density of freshwater floating feed is less than 440g/L, and that of seawater (20℃ seawater, 3% salinity) is less than 480g/L.

At the exit of the extruder and the outlet of the dryer are the bulk density of the wet material and the bulk density of the dry material respectively. It is impractical to measure the bulk density of the feed product after it is dry, so for any feed formula to know the bulk density of the dry material and the wet material relevance is very important.

The bulk density of the product is affected by the formula and processing parameters. The starch content in the formula has been mentioned above.

During the operation of the floating fish feed extruder machine, the variable parameters of the fish feed extruder include the template opening ratio, flow rate (material, steam , water, additive flow rate), host speed, barrel heating/cooling and material moisture, oil content, rated mechanical energy to achieve the required bulk density for processing.

- Usually, the opening rate is calculated based on 250mm² /t of floating material, 350mm² /t of slowly sinking feed, and 550mm² /t of sinking feed to calculate the number of openings of various specifications of die hole diameters.

- The operating moisture of floating feedis generally 21% to 25%. The operating moisture of the submerged material is generally 25% to 30%.

Grease addition

Oil and fat raw materials are the best energy sources for aquatic animals, and 2% to 40% of oil can be added to the formula according to the needs of aquatic organisms.

The source of oil can be obtained from dry materials, vegetable oil or animal oil, such as full-fat soybeans, soybean oil or fish oil.

In the actual operation of the twin-screw floating fish feed extruder machine processing technology, it is recommended that the fat content in the formula (the total fat content in the extruder) should be as low as possible or not exceed 12%.

- This recommended range is because when the oil content exceeds 12%, the fastness of the pellets will be significantly reduced.

- If the designed feed requires more than 12% oil content, the excess part can be used for external spraying after the feed is dry.

- It can be added by means of normal pressure or vacuum spraying according to the amount of content to be added.

The oil absorption of external spraying is related to the bulk density of the extrusion puffed product and the spraying method. The vacuum spraying method can achieve a higher oil absorption.

When vacuum spraying, the oil flows into the matrix of the granular material to replace the air in the cell space, and the exterior of the finished product Spraying grease can increase product density.

Processing of small-sized extruded pellet products

- For products with a die hole diameter less than Φ2.0mm, do not use cotton meal and rapeseed meal or raw materials with high fiber content in the formula, and achieve a certain crushing particle size (100% pass 80 mesh or reach 1/5 of the die hole diameter ).

- In addition, it is necessary to strengthen the cleaning of impurities during the processing process. Cleaning during the process is very important. Magnetic separation and screening must be strengthened. On the one hand, it can ensure the safe operation of the equipment, and on the other hand, it will greatly reduce the possibility of machine blockage.

- When processing large pellets and then switching to small pellets, it is necessary to clean up the residues in the process, and pay special attention to the conveying equipment (elevator, scraper conveyor, screw conveyor), the dead corner of the bucket and the quenching and tempering. The container must be cleaned very clean.

With the development and application of RICHI’s high-end special twin-screw machine for aquatic feed, we not only want to manufacture high-quality floating fish feed extruder machines, but also let customers fully understand and give full play to the advantages and characteristics of fish feed extruders.

So that the process can be processed with the minimum investment and minimum cost. The processing cost is the most ideal feed for aquatic animal breeding, and ultimately allows customers to obtain higher efficiency and greater economic benefits.

Complete Floating fish feed production line technology

In line with the benign development needs of global fish farming feed towards low pollution, low waste, high efficiency, and high conversion, aquatic extruded feed is gradually being accepted and recognized by the market, and has become a new trend in the development of the industry.

With the promotion and application of extruded feed in the breeding market, more and more fish feed factories have begun to introduce extruded equipment.

Many feed enterprises are upgrading their processes and production capacity through new construction, adding aqua feed extrusion production lines, and technological transformation to meet the opportunities and challenges of market development.

A single floating fish feed extruder machine certainly cannot meet the needs of commercial or industrial aquatic feed processing, which requires the establishment of a complete extruded feed processing system.

Standard floating fish feed Manufacturing process

cleaning – first crushing – first batching, mixing – second crushing – second batching, mixing – puffing – drying – cooling – after Spraying – packaging. We will provide customers with the most suitable process design and equipment configuration according to various factors such as raw materials, formulations, special process requirements, and factory buildings.

Extruded aqua feed mill equipment

A complete set of extruded feed processing system includes a series of feed equipment such as floating fish feed extruder machine, ultrafine pulverizer, dryer, mixer, sprayer, cooler, screening machine, and packaging machine.

Aquatic Feed Production Solutions

Our mission is to provide users with the most cost-effective floating fish feed machine solutions to help customers effectively reduce costs and enhance product competitiveness.

About Richi Machinery

Richi Machinery is a provider of aqua feed machinery equipment and whole fish feed mill plant engineering system solutions with the feed industry as the main body.

With nearly 30 years of word-of-mouth accumulation, the RICHI brand integrates R&D, production, sales and service, and is trustworthy! The equipment models are complete, and the product line includes floating fish feed, sunken fish feed, shrimp feed, and other special feed processing, involving various industries and fields, with diversified choices!

The team was formed in 1995 and has a history of nearly 30 years. The total area is more than 150 mu. At present, the total investment of the enterprise is nearly 30 million US dollars, and the annual output value is nearly 60 million US dollars. RICHI currently employs more than 150 people, and various scientific research and technical personnel account for more than 30% of the total number of the company.

RICHI has nearly 50,000 square meters of processing workshops. Introduce advanced technical equipment to provide excellent mechanical processing technology for each product. Equipped with laser cutting machine, CNC bending machine, vertical lathe, shearing machine, shot blasting machine, CNC automatic drilling machine, plate rolling machine, laser welding machine and other professional production equipment.

BV certification

CE certification

ISO certification

SGS certification

Richi Machinery’s characteristic products have obtained a number of patents, and all products have passed ISO international quality system certification, EU CE certification and customs union CU-TR certification, successfully serving more than 2,000 customers in more than 130 countries and regions around the world.

our service

All the services we provide are to ensure the operation of the client’s project.

Since Richi Machinery was established, we have always adhered to the service concept of “full life cycle, full value chain” to provide you with worry-free services throughout the life cycle from pre-sales, sales to after-sales, and integrate value-added services into every customer, any link closely related to customers.

Production line design

We have software and hardware resources and accumulated years of design experience to provide efficient and deeply customized production line solutions.

Equipment selection

There is always a demand for differentiated construction, and we will fully assist you in optimizing the selection of equipment to help you optimize the value of the purchased feed equipment.

Delivery and installation

In order to meet your needs, we will provide professional transportation solutions, and provide installation and commissioning services for each product.

Accessories

We supply all applicable accessories for your floating fish feed extruder machines. In order to deliver parts to customers’ production sites as soon as possible, Richi Machinery has built a special parts warehouse.

As long as the customer needs, we can quickly respond and deliver the goods from the warehouse in time, reducing customer waiting time and reducing the risk of equipment downtime.

Training

Our training instructors are all from the front line of service, have many years of rich practical experience, and have long-term professional skill training in production, operation, management, and maintenance. We have established a rigorous and thorough training system to help you cultivate operational, technical and management talents, and continue to create value for you.

Related Products

5-6 T/H Fish Feed Pellet Extruder

6-7 T/H Floating Feed Extruder Machine

LEAVE YOUR NEEDS

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622