Overview of 8 t/h Floating fish feed plant

The client of this 8t/h floating fish feed plant project was originally an aquaculture company, and all feeds were purchased from outside. Since feed prices are unstable and customers have always been very interested in the field of feed processing, starting in 2017, customers intend to invest in aquatic feed processing business and penetrate the aquatic industry chain services. Therefore, some of the products of this project are used by the customer’s farm itself.

The development level of the feed industry determines the development level of a country’s breeding industry, and it is also one of the important symbols to measure the development of modern agriculture. The feed industry determines the future of the aquaculture industry. It is an important means to develop the aquaculture industry and realize the modernization and commercialization of the aquaculture industry. It is closely related to the national economy and people’s lives. contribute.

The development of the fish feed production industry has significant economic and social benefits. Therefore, the client of this project built a new fish feed production line with an annual output of 20,000 tons. The 8t/h floating fish feed plant project uses corn, soybean meal, flour, rapeseed meal, peanut bran, vegetable oil, etc. as raw materials to produce fish feed. The project covers an area of 4640 square meters, with a green area of 100 square meters.

Construction scale

The overall layout of the fish feed factory project is unified and coordinated, the functional divisions are clear, the buildings and structures are not only compact and reasonable, the circulation is smooth, and the layout of the project is reasonable.

- Raw material workshop: 1 floor, mainly storing corn, soybean meal, flour, rapeseed meal, peanut bran and vegetable oil;

- Main production workshop: 1 floor, the main equipment is pulverizer, mixer, dryer, baler;

- Finished product workshop: 1 floor, where the packaged finished products are stored.

Main equipment for 8 t/h floating fish feed plant

| Device Name | QTY |

|---|---|

| Material receiving system | 1 |

| Smashing System | 1 |

| Ingredient System | 1 |

| Secondary crushing system | 1 |

| Secondary batching system | 1 |

| Expansion drying system | 1 |

| Spray packaging system | 1 |

| Forklift | 2 |

| Biomass boiler 6t/h | 1 |

Main raw materials

The 8t/h floating fish feed plant project is to build a new main fish feed pellet production line, and the raw materials are soybean meal, fish meal, flour and so on.

| Name | Annual consumption (t/a) |

|---|---|

| Corn | 3600 |

| Soybean Meal | 4400 |

| Flour | 4000 |

| Rape meal | 3000 |

| Peanut bran | 3000 |

| Vegetable oil | 2000 |

Number of employees and working system

- Number of employees: There are 18 employees in the project, all of whom will have board and lodging on site.

- Working system: One shift is adopted, the daily working time is 8 hours, and the annual production is 300 days.

Water and electricity consumption

The production power supply of this 8t/h floating fish feed plant project adopts double-circuit power supply. The power supply is introduced from the nearby high-voltage line and is stepped down by the transformer to 380/220 volt three-phase four-wire, and then sent to the workshop by the low-voltage power distribution cabinet. The total electricity consumption is 270,000 kWh/year.

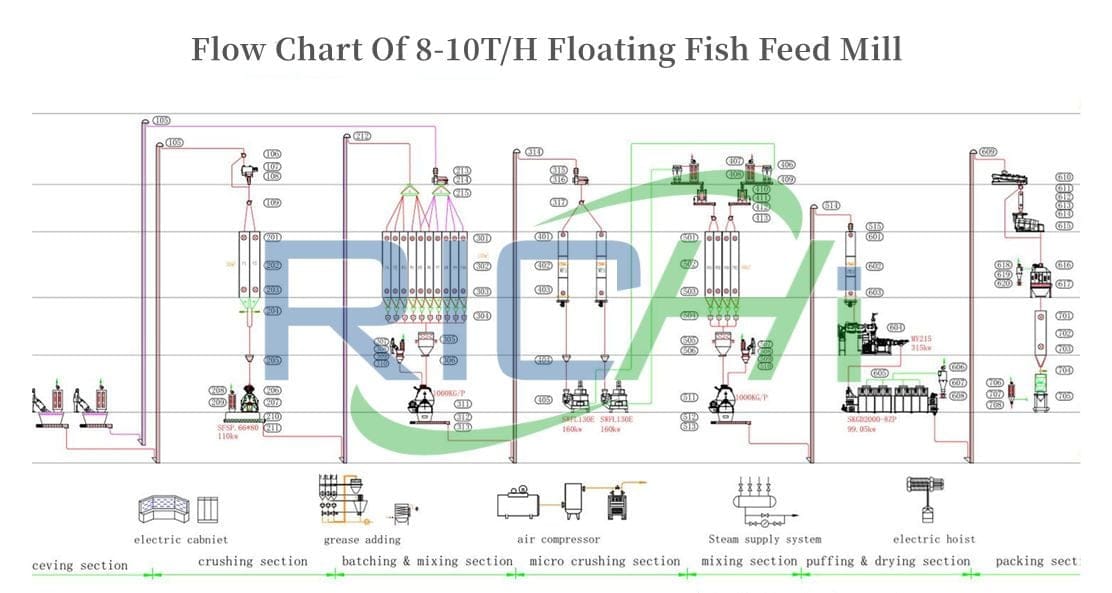

Process flow design of 8 t/h floating fish feed plant

After the purchased raw materials are transported to the factory’s raw material warehouse for storage, they are transferred to their respective feeding ports. First, the larger particle raw materials are coarsely crushed, and other raw materials are added to the crushed raw materials according to the specified proportion and stirred and mixed.

Then all raw materials enter the super pulverizer further pulverizes and fully mixes, and then transfers to a closed container, heats and pressurizes the raw materials to expand, and finally packs the product as required after drying.

- Receipt of raw materials: The raw materials of the project are all packed in plastic bags, and the raw materials are temporarily stored in the raw material warehouse after purchase. Put the raw materials that need to be pulverized into the raw material tank.

- Crushing: This process is mainly for coarse crushing of the pellets that need to be crushed, and the pellets in the crushing bin are crushed and then enter the batching bin.

- Ingredient mixing: According to the preset feed formula requirements, raw materials that do not need to be coarsely crushed are added, and are transported by the auger conveyor into the batching scale for cumulative measurement. The mixing is mainly done by a double-shaft paddle high-efficiency mixer. After each material enters the mixer, it is gradually mixed evenly through the mechanical action of the paddle.

- Superfine pulverization: The pulverization process of the whole 8t/h floating fish feed plant production process includes crushing and superfine pulverization. After the materials are initially mixed, they enter the superfine pulverization. The amount of superfine pulverization is adjusted according to the product requirements, and the pulverized materials enter the secondary mixing.

- Secondary mixing: The mixing process includes ingredient mixing and secondary mixing. The secondary mixing is mainly to fully mix the ultrafine powdered raw materials to prevent uneven mixing caused by uneven ingredients and primary crushed raw material particles.

- Puffing: The raw materials are in a closed container, and the product is expanded by heating and pressurizing.

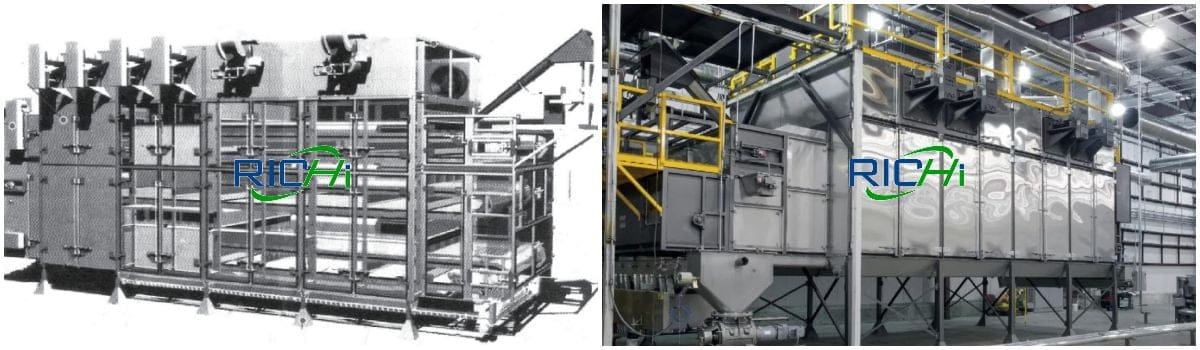

- Drying: Heating by biomass briquette fuel steam boiler to dry the moisture in the feed.

- Packing: pack the dried products in bags.

Note:

Rapeseed meal, soybean meal, etc. are included in the raw materials of this project, and these raw materials will emit peculiar smell during the process of puffing and drying. In addition, due to the large amount of raw materials stored in the raw material storage yard, a certain amount of peculiar smell will also be emitted.

Raw material piles produce less peculiar smell, and the peculiar smell can be effectively controlled by adopting closed disposal and placing them in a relatively closed storage room.

During the production process of the 8t/h floating fish feed plant project, dust will be generated in raw material receiving tank, crushing, ingredient mixing, superfine crushing, secondary mixing and other processes. The main production process of the project is carried out in relatively closed equipment, and the generated dust is treated by pulse bag filter 35m high exhaust pipe discharges, and a small amount of uncollected discharge is fugitive discharge.

Raw materials in different regions and different processing techniques have different effects on fish. RICHI will continue to help customers analyze, refine, summarize and continuously improve relevant databases to provide stronger support for improving the competitiveness of feed products.

Since aquatic feed products are closely related to the safety of aquatic food, as a company with technical background, the client company has always regarded improving product quality as an important means to enhance the core competitiveness of the company. (Related solution: fish feed manufacturing plant)

At present, the client company has passed ISO9001 quality management system and ISO22000 food safety management system certification, and established and improved the internal quality management system.

From the procurement, testing, warehousing and receiving of raw materials, to the whole-process tracking of key control points in the production of 8t/h floating fish feed plant, to the packaging, warehousing, verification and delivery of products, the customer has established strict control over every link Procedures, and can be implemented consistently, thus providing a strong guarantee for the stability of product quality.

Customer characteristics

- Aquafeed uses fish meal, chicken meal, soybean meal, rapeseed meal, flour, etc. as the main raw materials. The cost control of raw materials, especially the cost control of fish meal, is of great significance to aquatic feed manufacturers. The client company conducts centralized procurement of important raw materials such as fish meal, and the procurement volume is large, which can obtain advantageous purchase prices.

- According to market segments, the client company established a dedicated procurement team, established a professional information research model based on raw material database and raw material market price database, improved the ability to predict fluctuations in raw material market prices and procurement efficiency, and effectively controlled raw material costs.

Relying on years of experience in raw material procurement and industry competitive advantages, the customer company has strong bargaining power in raw material procurement, and has a group of suppliers with long-term strategic partnerships to ensure that the customer company can obtain high-quality, sufficient, stable and price-advantaged raw material supply.

At the same time, through long-term research and development and experience accumulation, the client company has established a systematic database for the cost performance and utilization efficiency of various raw materials, so that it can purchase and use relevant raw materials in a timely manner according to market conditions. (Related post: 6t/h aquatic feed mill)

With this 8t/h floating fish feed plant, with excellent product quality, differentiated series of products and high cost performance brought by refined cost management, the client company’s products have established a good reputation in the industry, and have been recognized and praised by dealers and farmers.