Overview of 5T/H Fish Food Machine in Uzbekistan project

The 5t/h sinking fish food machine in Uzbekistan project extensively draws on the advanced technology of feed machinery, and selects a combination of equipment with superior performance, which is composed of a fish feed pulverizer, a sinking fish feed pellet machine, a fish feed mixer, a fish feed cooler, and a screening machine.

Automatic feeding, fast feeding, smooth and uniform discharging, automatic temperature rise during the granulation process, gelatinization, aging, and granulation are completed at one time, the thickness can be adjusted within 1.5mm-4mm according to the needs of users, the surface of the granules is smooth, moderate hardness, easy to seal and store.

- Project date: 2017.08——2017.11

- Project location: Uzbekistan

- Equipment output: 5 Tons Per Hour

- Application: Production of catfish feed

- Feed Size: 1.5-4mm

- Complete Fish Food Machine System Price: 100,000-290,000 USD

In August 2017, this customer from Tashkent, Uzbekistan sent an inquiry:

“I am currently interested in knowing what the current price of buying and installing a sinking fish food machine in Uzbekistan. The one with 5-7T/H. Thanks”.

In November 2017, the 5t/h sinking Fish Food Machine in Uzbekistan project was signed.

The 5t/h sinking fish feed machine for sale Uzbekistan project can process not only fish feed, but also pellet feed for cattle, sheep, rabbits, chickens, ducks, etc.; it can process pellet feed and powder feed. It is a feed production line suitable for multiple purposes.

The customer has its own large fish farm, and all the processed fish feed will be used for carp farming. In the following 2018-2021, this customer also purchased a full set of 3-5 t/h poultry feed production line, a full set of 5-7 t/h livestock feed line and stainless steel cooler from us.

Next, RICHI will introduce the design and equipment configuration of this project.

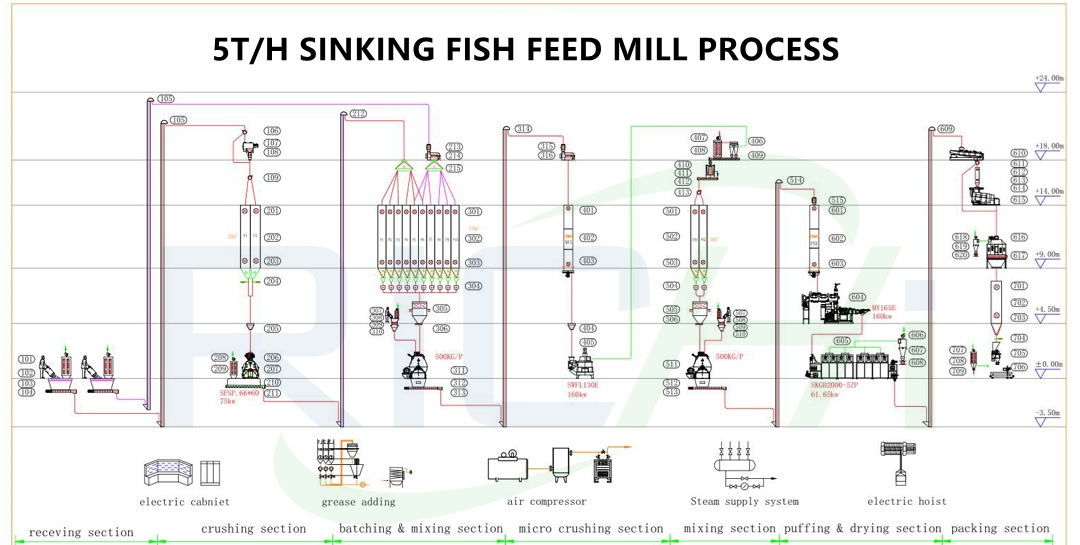

Process Design Of Complete 5T/H Fish Food Machine in Uzbekistan

When designing the aquatic feed processing technology, we fully understood the main product types, feed formula, production capacity, automation requirements and investment amount of Uzbekistan customers.

According to the actual needs and budget of customers, we design a variety of plans, comprehensively consider, adopt advanced and complete fish feed mill plant process flow, advanced equipment and highly automated control equipment to ensure product quality, reduce energy consumption as much as possible, and reduce production costs.

Technological process of 5t/h sinking Fish Food Machine in Uzbekistan:

- Materials receiving& pre-cleaning system

- Crushing system

- Batching& mixing system (Computer controlled)

- Pelletizing& cooling& screening system

- Packing& dust collecting system

- Oil adding system

- MCC Control Center ;Mimic Control Panel

List Of Complete System 5T/H Fish Food Machine in Uzbekistan

In order to obtain high-quality aquatic feed, it is necessary to focus on the feeding characteristics of aquatic products fed by the main product, ensure all the nutrients it needs, adopt reasonable aquatic feed processing technology, and select appropriate processing equipment.

The following is the main equipment list for this aqua feed mill project:

| 1.Materials receiving& pre-cleaning system | |||

| NO. | NAME | MODEL | QTY |

| 101 | Feeding hopper with grids | / | 2 |

| 102 | Bucket elevator | TDTG36/28 | 1 |

| 103 | Bucket elevator | TDTG36/28 | 1 |

| 104 | Drum type precleaner | SCY63 | 1 |

| 2.Crushing system | |||

| 201 | Upper level indicator | KF1500 | 2 |

| 202 | Cone bucket | / | 2 |

| 203 | Lower level indicator | KF1500 | 2 |

| 204 | Pneumatic gate valve | TZMQ40A | 2 |

| 205 | Buffer bin | / | 1 |

| 206 | Variable frequency feeder | SWLY20X80 | 1 |

| 207 | Fish Feed Hammer mill | SFSP66*80 | 1 |

| 208 | Draft fan | 4-72-5A | 1 |

| 209 | Pulse dust collector | TBLMa.36A | 1 |

| 210 | Settling chamber | / | 1 |

| 211 | Screw conveyor (air locked) | TLSS25 | 1 |

| 212 | Bucket Elevator | TDTG36/28 | 1 |

| 213 | Rotary distributor | TFPX8 | 1 |

| 3. Batching & SEC-mixing system | |||

| NO. | NAME | MODEL | QTY |

| 301 | Upper level indicator | KF1500 | 10 |

| 302 | Cone bucket | / | 10 |

| 303 | Lower level indicator | KF1500 | 10 |

| 304 | Outlet Screw conveyor | PLSS25/20/16 | 10 |

| 305 | Batching scale | PLC1.0A | 1 |

| 306 | Pneumatic gate valve | TZMQS60A*2 | 1 |

| 307 | Premix adding hopper | / | 1 |

| 308 | Small material checking balance | PLC0.1B | 1 |

| 309 | Pneumatic gate valve | TZMQ25B | 1 |

| 310 | Fish Feed mixer | SLHJ2A | 1 |

| 311 | Buffer bin | 2.5m³ | 1 |

| 312 | Scraper conveyor | TGSU20 | 1 |

| 313 | Bucket Elevator | TDTG36/28 | 1 |

| 314 | Permanent magnetic sleeve | TCXT20 | 1 |

| 315 | Powder precleaner | SCQZ60*50*100 | 1 |

| 316 | Rotary distributor | TFPX4 | 1 |

| 4. Pelletizing& cooling& screening system | |||

| NO. | NAME | MODEL | QTY |

| 401 | Upper level indicator | KF1500 | 2 |

| 402 | Cone bucket | / | 2 |

| 403 | Lower level indicator | KF1500 | 2 |

| 404 | Pneumatic gate valve | TZMQ40A | 2 |

| 405 | Under the hopper | / | 1 |

| 406 | Sinking fish feed machine & 2-Layer Conditioner | SZLH420 | 1 |

| 408 | Cooling Machine | SKLN20x20 | 1 |

| 409 | Crumbler | SSLG15*150 | 1 |

| 410 | Rotary screener | SFJH125*2C | 1 |

| 5. Packing& dust collecting system | |||

| NO. | NAME | MODEL | QTY |

| 501 | Upper level indicator | KF1500 | 2 |

| 502 | Cone bucket | / | 2 |

| 503 | Lower levle indicator | KF1500 | 2 |

| 504 | Pneumatic gate valve | TZMQ30A | 2 |

| 505 | Buffer bin | / | 1 |

| 506 | Automatic Packing machine | DCS-50 | 1 |

| 507 | Sewing machine,belt conveyor | / | 1 |

| 508 | Manual pick up mouth | TZMS25 | 1 |

| 6. Oil adding system | |||

| NO. | NAME | MODEL | QTY |

| 601 | Heating oil storage tank | SYTZ100 | 1 |

Auxiliary Equipment

| Air compressor system | 22KW | Including air compresser, air tank, drying machine. |

| Bolier System | 1.0T | Quantity of steam 1.0T/H 0.7Mpa,horizontal type. with control cabinet, accessories. |

| Electric Hoist System | 4T, 1.5*1.5*24m | Including Elctric hoisting system, hanging basket,Vertical Shaft, lead rail . |

Advantages of RICHI sinking Fish Food Machine in Uzbekistan

Richi Machinery has been adhering to the principle of high quality in recent years. It knows that improving product quality can bring greater benefits to customers, reduce waste of raw materials, and improve market competitiveness.

There are also various ways to improve product quality, among which better key equipment and its auxiliary devices are an important way to achieve quality improvement.

Let’s learn about the advantages of the key equipment of RICHI’s sinking fish food machine for sale the world.

- The advanced impeller feeder and sieve breaking detection device in the crushing section guarantee the quality of the crushing; the automatic control of the crushing fineness ensures balanced nutrition. The bearing temperature and the vibration of the grinder are out of tolerance alarm, and the relevant personnel are notified in time to deal with it to avoid equipment failure The loss of raw materials and product quality problems caused by it.

- Improve the batching system in the mixing section, the automatic calibration scale avoids manual handling of weights, improves the calibration accuracy, and can also improve the safety and hygiene of the feed. Advanced batching algorithm, automatic calculation of drop, and frequency conversion feeding at the same time, adjust in time to ensure accuracy. Manual feeding of small materials can be replaced by a micro scale system, which directly enters the mixer, avoiding the waste of high-cost raw materials.

- The pelleting section adopts a brand-new conditioner, which greatly reduces the discharge of the head material, enters the production process faster, and also makes the feed safer and reduces the labor intensity. The pressure roller of the 5t/h sinking pellet fish food machine in Uzbekistan is automatically adjusted, it can increase the work efficiency by about 85%, and also reduce the requirements for operators.

- Energy saving and reducing energy consumption are the basis for enterprises to obtain good economic benefits. RICHI fish feed mill machines can monitor the “health status” of the equipment in real time, so that the equipment can always maintain high-efficiency operation. Timely remind the best time to replace key accessories…these These are the key “magic weapons” for RICHI to reduce energy consumption in the feed production process. At the same time, we will also seek a more energy-saving implementation method that is different from the traditional ones on auxiliary devices, so that the work of energy conservation and efficiency enhancement will flourish.

- In other nodes in the factory, use advanced auxiliary devices and more reasonable process design to reduce labor, or reduce the requirements for the ability of operators as much as possible, and reduce the length of training. Online training can be used to reduce personnel gathering and training time. Save personnel costs, and create more benefits.

We have been systematically helping customers to solve the demand for high value-added aquatic feed, as well as the high professional level of the aquatic feed industry and the high requirements for hygiene and environmental protection. These are also the tasks that our professional R&D and service teams are doing their best.

If you are interested in our 5t/h sinking fish food machine in Uzbekistan project, and you also want to build or renovate your aquafeed factory, please feel free to contact us to customize the most suitable plan for you.