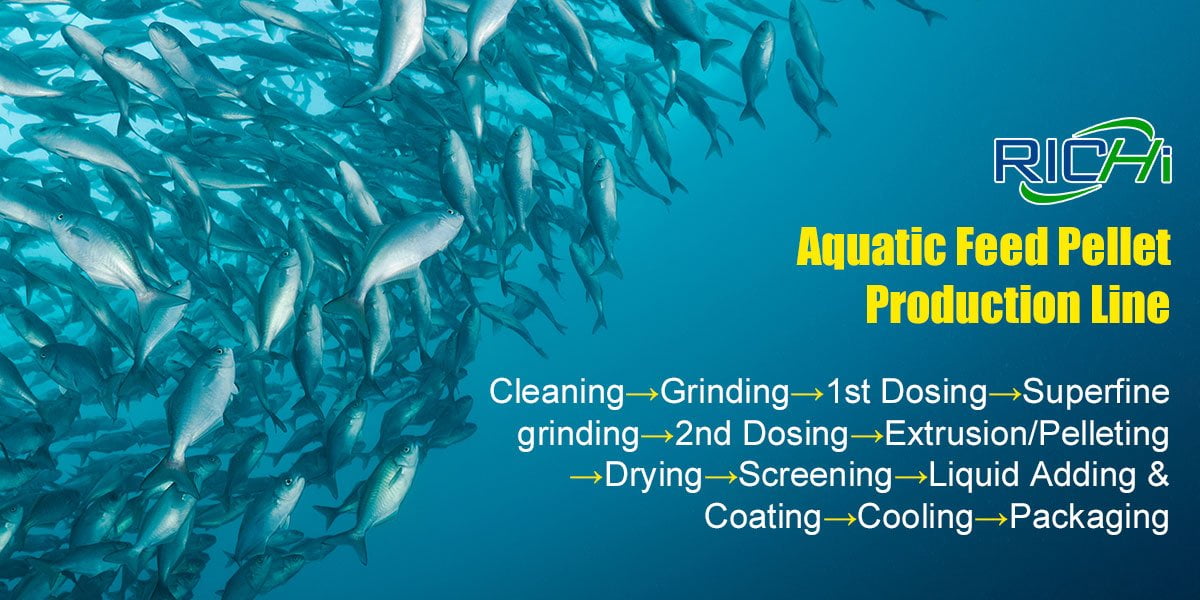

The floating fish feed production line is an aquatic feed processing system specially designed for extruded feed, and is suitable for the processing of various types of extruded aquatic feed, pet extruded feed, and livestock and poultry extruded feed.

Richi Machinery is committed to providing customers with high-quality 1-60t/h floating fish feed line equipment and providing multi-faceted technical support.

According to the attributes of different fish feeds such as floating catfish food, floating trout pellets, floating betta food, tilapia floating fish feed, etc., the configuration and construction plan of the floating fish feed pellet production line are customized.

At the same time, optimize the combination of various types of equipment to finally meet the customer’s demand for high-yield and low-consumption extruded feed processing.

floating fish feed production line solution

- The scope of the floating fish feed mill design includes the production area, office and living area, as well as the relevant off-site railway and highway special lines, etc.;

- The content of the design includes the general plan, process, auxiliary production system, information system and civil engineering, etc.;

- Process design mainly includes the formulation of floating fish feed making process flow and equipment selection, workshop structure and equipment layout, transportation network and ventilation and dust removal network, workshop self-made equipment and facilities, and silo layout, etc.;

- The design of auxiliary production system mainly includes steam supply system and compressed air system, power distribution and transmission system, water supply and drainage engineering, environmental protection engineering and machine repair, accessories room, woven bag warehouse, label warehouse, etc.;

- Information system design mainly includes information management system (management software, monitoring, network), testing system and production automatic control system;

- Civil engineering design of the floating fish feed production line mainly includes the general plan, various buildings and structures, and roads.

With the rapid development of the aquaculture industry, the traditional breeding methods are far from meeting people’s needs. The requirements for aquatic feed are not only balanced nutrition, good stability of the feed in water, etc., but also the environment in which animals live——The quality of water bodies puts forward more stringent requirements.

Therefore, the requirements for aquatic feed processing technology are getting higher and higher. Better feed technology means better feed quality, higher feed processing efficiency and better breeding effect.

Featured floating fish feed production line design

Over the past decades, we have accumulated rich practical experience, tailored reasonable and practical scheme configurations for thousands of customers, and provided a full set of services throughout pre-sales, sales and after-sales. Below, RICHI will list several characteristic floating fish feed manufacturing line designs and equipment configuration solutions.

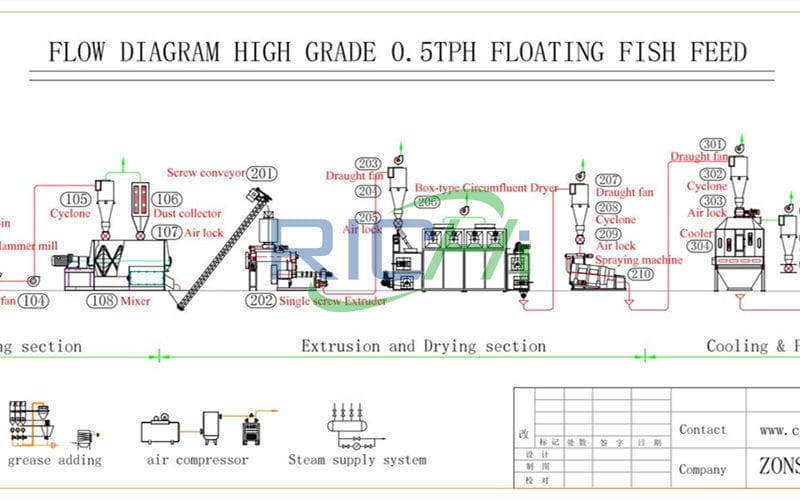

1.8-2T/H(Wet Type)Floating Fish Feed& Pet food Complete Line

- Application: floating fish feed

- Cost: 300000USD

- Floating fish feed production process:Crushing system——Mixing system——Extruding system——Packing system ——Electrical control system

Main equipment:

| Fish food grinder | SFSP66*60 | 1 |

| Fish feed mixer machine | SLHY1.0A | 1 |

| Extruder machine for fish feed | RCPH120*2 | 1 |

| Fish feed drying machine | DHG-2000Q | 1 |

| Coating machine | RISP-2000 | 1 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS80 | 1 |

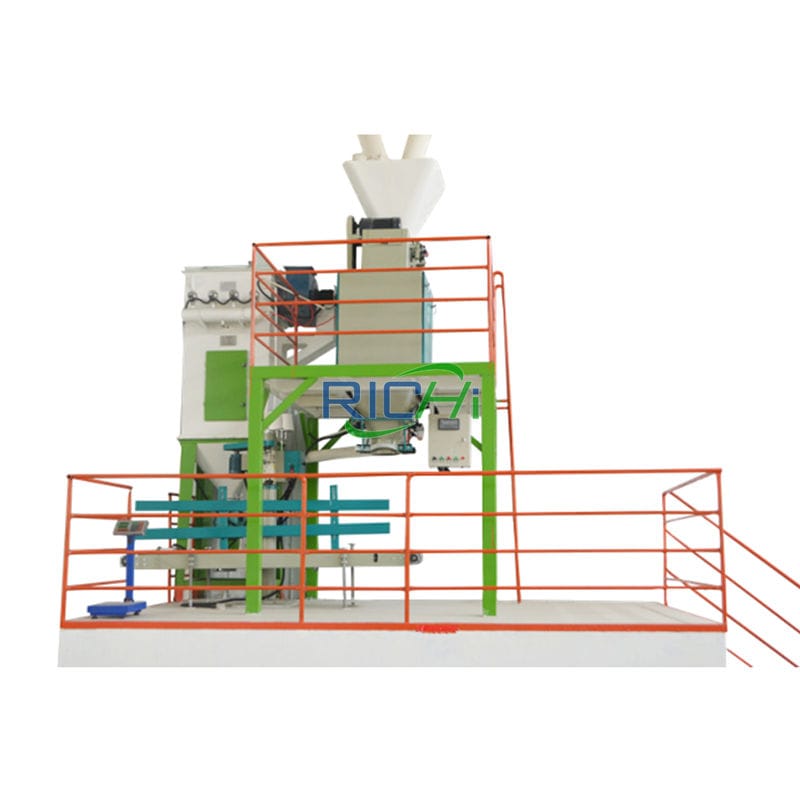

| Auto-packing machine | DCS-50 | 1 |

Auxiliary equipment:

Screw conveyor*TLSS20, Bin before crusher*2.5m³, Draught fan*4-72-3.2A, Pulse dust collector*TBLMa.12B, Air-locked screw conveyor*TLSS20, Bucket elevator*TDTG36/18, Bin before mixer*1m³, Screw conveyor*TLSS20, Permanent magnetic sleeve*TCXT20, Pre-Crushing bin*1m³, Pulse dust collector*TBLMa.24A, Screw conveyor (Air locked)*TLSS20, etc.

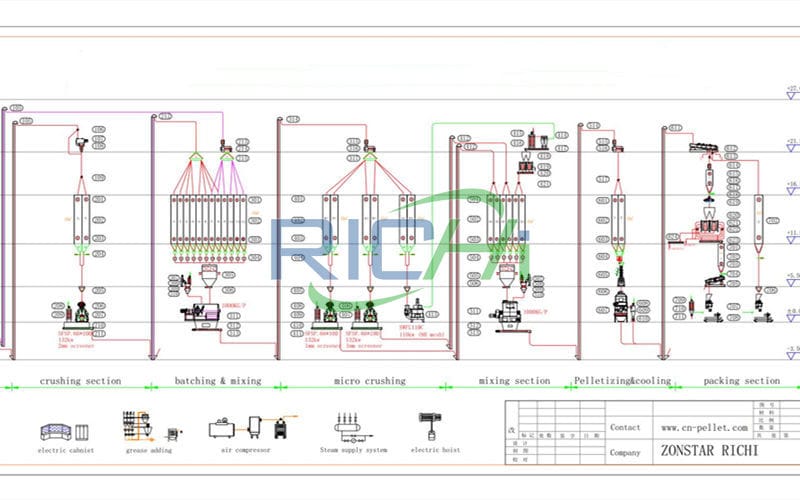

3TPH High Quality floating fish feed production line

- Application:extruded feed pellets

- Cost:646200 USD

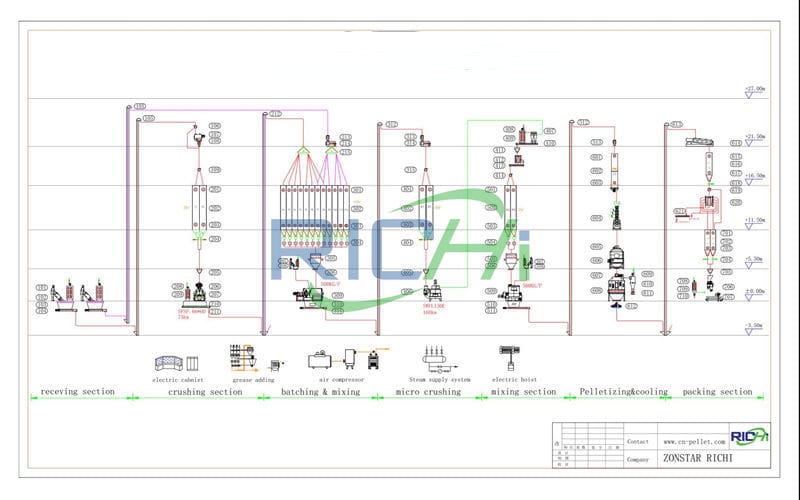

- Floating fish feed production process:Raw materials recieving and crushing system——First-time crushing system——First-time batching and mixing system——Fine crushing system (Second-time crushing system )——Second-time mixing system——Puffing and drying system ——Automatic packing system——Oil adding system——MCC Control Center ;Mimic Control Panel

Main equipment:

| Fish feed hammer mill crusher | SWSP66*60 | 1 |

| Batching scale | PLC0.5A | 2 |

| Double ribbon mixer | SLHY1.0A | 2 |

| Ultrafine grinder | SWFL110C | 1 |

| Floating feed extruder machine | RCPH120*2 | 1 |

| Fish feed dryer machine | SKGD200-3ZP | 1 |

| Rotary screener | SFJH125*1 | 1 |

| Coating machine | YPLV80 | 1 |

| Cooling machine | SKLN17*17 | 1 |

| Automatic packing machine | DSC-50 | 1 |

| Oil/Liquid adding system | SYTZ100 | 2 |

Auxiliary equipment:

Draught fan*4-72-3.2A, Pulse dust collector*TBLMa.12, Bucket elevator*TDTG40/23, Drum pre-cleaner*SCY63, Pulse dust collector*TBLMa.36, Air-locked conveyor*TLSS20, Permanent magnet drum*TCXT20, Powder pre-cleaner*SCQZ60*50*100, Rotary distributor*TFPX6, etc.

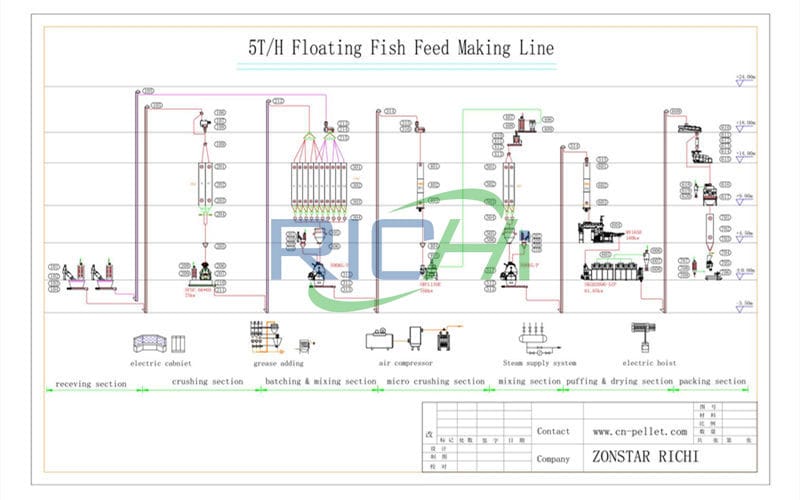

5TPH complete Floating Fish Feed production Line

- Application: extruded fish feed production

- Cost :USD 961660

- Floating fish feed production process:Raw materials recieving and crushing system——First-time crushing system——First-time batching and mixing system——Fine crushing system (Second-time crushing system )——Second-time mixing system——Puffing and drying system——Automatic packing system——Oil adding system——MCC Control Center ;Mimic Control Panel

Main equipment:

| Hammer mill feed grinder | SWSP66*60 | 1 |

| Rotaory distributor | TFPX6 | 1 |

| Batching scale | PLC0.5A | 2 |

| Feed mixer machine | SLHJ1A | 2 |

| Ultrafine grinder | SWFL130E | 1 |

| Fish feed dryer machine | SKGD200-5ZP | 1 |

| Coating machine | SYPL15C | 1 |

| Fish feed extruder | RCPH150*2 | 1 |

| Rotary screener | SFJH125*1 | 1 |

| Cooling machine | SKLN17*17 | 1 |

| Automatic packing machine | DSC-50 | 1 |

Auxiliary equipment:

Draught fan*4-72-3.2A, Pulse dust collector*TBLMa.12, Inlet hopper, Scraper conveyor*TGSS20, Bucket elevator*TDTG40/23, Pnenmatic three-way*YSTZ22A, Drum pre-cleaner*SCY63, Storage bin, Premix scale*PLC0.1B , Double cyclone*SK800*2, Oil/Liquid adding system*SYTZ100, etc.

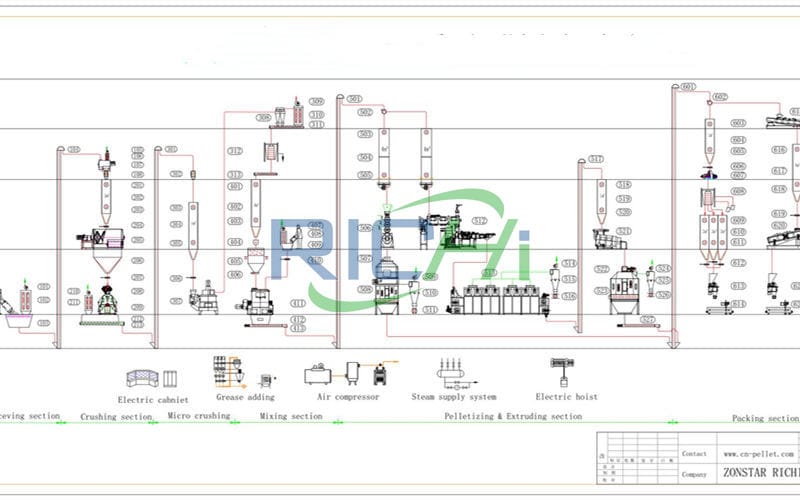

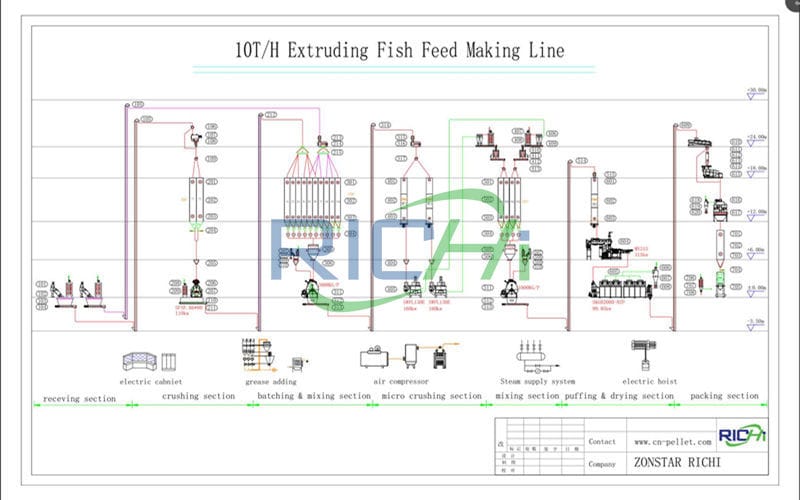

10TPH Floating Fish Feed extrusion Line

- Application:extruded feed

- Cost :USD 1250340

- Floating fish feed production process:Raw materials recieving and crushing system——First-time crushing system——First-time batching and mixing system——Fine crushing system——(Second-time crushing system )——Second-time mixing system——Puffing and drying system——Automatic packing system——Oil adding system——MCC Control Center ;Mimic Control Panel

Main equipment:

| Fish food grinder machine | SFSP66*80 | 1 |

| High efficiency fish feed mixer | SLHJ2A | 2 |

| Micro pulverizer | SWFL130E | 2 |

| Floating feed extruder | RCPH185*2 | 1 |

| Drying machine | SKGD200-8ZP | 1 |

| Rotary screener | SFJH150*1 | 1 |

| Coating machine | SYPL25C | 1 |

| Pellet cooler machine | SKLN20*20 | 1 |

| Automatic packing machine | DSC-50 | 1 |

| Oil/Liquid adding system | SYTZ200 | 2 |

Auxiliary equipment:

Draught fan*4-72-3.2A, Pulse dust collector*TBLMa.12, Bucket elevator*TDTG50/28, Pnenmatic three-way*YSTZ22A, Permanent magnet drum*TCXT20, Pulse dust collector*TBLMa.48, Powder pre-cleaner*SCQZ60*50*100, Rotary distributor*TFPX6, Batching scale*PLC1.0A, Premix scale*PLC0.1B, Scraper conveyor*TGSU20, Storage bin*2m3, etc.

5-6T/H Animal Feed & 3-4T/H pet food & Floating Fish Feed combined Line

- Application: floating feed, pet food & poultry livestock feed production

- Cost: USD 186960

- Floating fish feed production process:Crushing and mixing system——Extruding system and pelletizing system——Cooling and Packing system——Oil adding system——MCC Control Center

Main equipment:

| Stainless steel hammer mill | SFSP66*60 | 1 |

| Fish feed mixing machine | SLHY2.5L | 1 |

| Floating fish pellet extruder | RCPH120*2 | 1 |

| Animal feed pellet machine | SZLH350 | 1 |

| Aqua feed drying machine | RH-WH2200 | 1 |

| Oil spraying machine | 1 | |

| Cooling machine | SKLN17*17 | 1 |

| Automatic bagging machine | DCS-50 | 1 |

| Oil adding machine | YZTG100a | 1 |

| Boiler system | 1.5T,0.7Mpa | 1 |

| Air compressor and srorage tank | 11KW | 1 |

Auxiliary equipment:

Screw conveyor*TLSS20, Buffer bin*2.5 m³, Pulse dust collector*TBLMa.24a, Settling chamber, Screw conveyor (air locked)*TLSS20, Bucket elevator*TDTG36/18, Pneumatic gate valve*TZMQ30A, Draft fan*4-72-4A, Cyclone*ф1000, etc.

2T/H Floating fish feed production line& 5-6T/H animal feed line

- Application:extruded fish feed, shrimp feed, poultry livestock feed

- Cost:247290 USD

- Floating fish feed production process:PLC Dosing/Batching System( With 4 sets 20 Ton Silo )——Crushing and mixing system——Extruding and drying system——Cooling and packing system——Oil adding system——Electrical control system

Main equipment:

| Feed hammer mill grinder | SFSP56*40 | 1 |

| Aqua feed mixing machine | SLHY1.0A | 1 |

| Animal feed pelleting machine | SZLH350 | 1 |

| Fish food extruder machine | RCPH120*2 | 1 |

| Drying machine for fish feed | RH-WH2000 | 1 |

| Cooling machine | SKLN17*17 | 1 |

| Sewing + belt conveyour | 1 | |

| Auto-packing machine | DCS-50 | 1 |

| Oil/water adding machine | YZTG100a | 1 |

Auxiliary equipment:

Discharging pit, Well shape frame(2.0*2.0*16m), Bucket elevator*TDTG36/28, Screw conveyor*TLSU20, Rotary distributor*TFPX-4, Cone Silos(φ3.67m*1.5C Volume 32.67m³ 22T), Batching scale*PLC0.5A, Weighting PLC screen*PLC-100, Pulse dust collector*TBLMa.12a, Stainless steel anti-caking bin*2m³, Stainless steel conditioner*TZ35*200, etc.

Floating fish feed production line project

For decades, RICHI’s floating fish feed pellet production line equipment has taken root in countries all over the world with solid product quality and services, and has served thousands of customers successively.

1.5-2T/H

1.5-2T/H Twin-screw Floating Fish Production Line & Shrimp Feed Line In Iran

1.5-2T/H

1.5-2T/H Floating Fish Feed Machine Plant In Russia

1T/H

1T/H Floating Fish Feed Mill Plant & 2*5-7T/H Poultry Feed Plant In Zimbabwe

1-1.2T/H

1-1.2T/H Floating Fish & Cattle Feed Production Line In Uzbekistan

1T/H

1T/H Wet Type Floating Fish Feed Mill In Honduras

Under the concept of environmental friendliness and ecology friendliness, it has participated in local feed processing construction and agricultural resources development, create more value for customers, and become a beautiful local landscape.

Process Design of floating fish feed production line

According to the characteristics of many varieties of aquatic feed, large changes in raw materials, high requirements for crushing fineness, and poor fluidity of materials, RICHI floating fish feed making line generally adopts secondary crushing and secondary ingredient mixing in the production process, and then undergoes puffing, drying, Spraying, cooling, crushing and screening to complete the processing of aquatic extruded feed.

(1) Cleaning of raw materials and primary crushing

There are generally two forms of raw materials used in aqua feed mills:

- Powder, no coarse crushing is required. Directly enter the cleaning sieve for impurity removal, and then perform magnetic separation to participate in the first batching;

- Coarsely crushed material – pellets. After impurity removal and magnetic separation, it is coarsely crushed by a pulverizer, and then enters the batching bin to participate in the first batching.

- Individual raw materials, such as shrimp shells, can be directly separated into the bin to be crushed after being magnetically separated without the initial cleaning.

The first coarse crushing is the pretreatment process of superfine crushing in aquatic floating fish feed production line. Its main purpose is to reduce the particle size difference and variation range of materials, improve the working condition of the superfine pulverizer, and improve the working efficiency of the superfine pulverizer. , To ensure the stability of product quality.

(2) The first batching and mixing

The first batching is mainly the preparation of bulk raw materials, that is, the preparation of relatively large materials in the formula.

The first batching and mixing are also the pretreatment process of ultrafine pulverization, which is mainly to reduce the variation range of material particle size, improve the working condition and efficiency of the pulverizer, and ensure the quality of the product.

(3) Secondary grinding and mixing of secondary ingredients

In the secondary crushing process, the primary mixed materials are lifted by the elevator and then enter the bin to be crushed, and then enter the fine pulverizer. The material after the second crushing is subjected to secondary batching and mixing. Various raw materials enter the secondary mixer after secondary batching.

In the secondary mixing process, various materials must be fully mixed, and the coefficient of variation CV is less than 7%, which is the key to ensuring product quality.

(4) Extrusion and granulation process

In the extrusion process of floating fish feed production line, the material is extruded by an extruder to form wet and soft granules (moisture content is 25% to 30%). Due to its high moisture content, it must be dried in a dryer to make the material dry. Moisture drops to around 13%.

In the previous process, the nutrients that should not be added can be supplemented by external spraying, which can also improve the palatability of the feed and reduce the powder content.

The optimum working temperature for this process is around 80°C. After the material passes through the external spraying system, it can enter the counterflow cooler for cooling.

(5) Finished product processing and packaging

After being transported by the bucket elevator, the cooled material is crushed and enters the rotary screen for classification. The grading sieve is generally a two-layer sieve:

- The material on the lower sieve is the finished product, which can be directly put into the finished product warehouse, and then weighed and packaged.

- The material on the upper sieve needs to be returned to the crusher for crushing.

- The material under the lower sieve is generally finely crushed material, which can be returned to the batching bin as waste.

The above floating fish feed production line process is the conventional configuration of the current aquatic extruded feed processing technology. Using this process, extruded floating feed and extruded sinking feed can be produced.

Nowadays, as a new type of aquatic feed mill technology, the extruded feed processing technology has been recognized by more and more feed manufacturers.

Floating fish feed extrusion technology is the development trend of feed processing industry in the future, especially in the application of aquatic feed and pet feed, it will replace the traditional hard pellet feed processing technology.

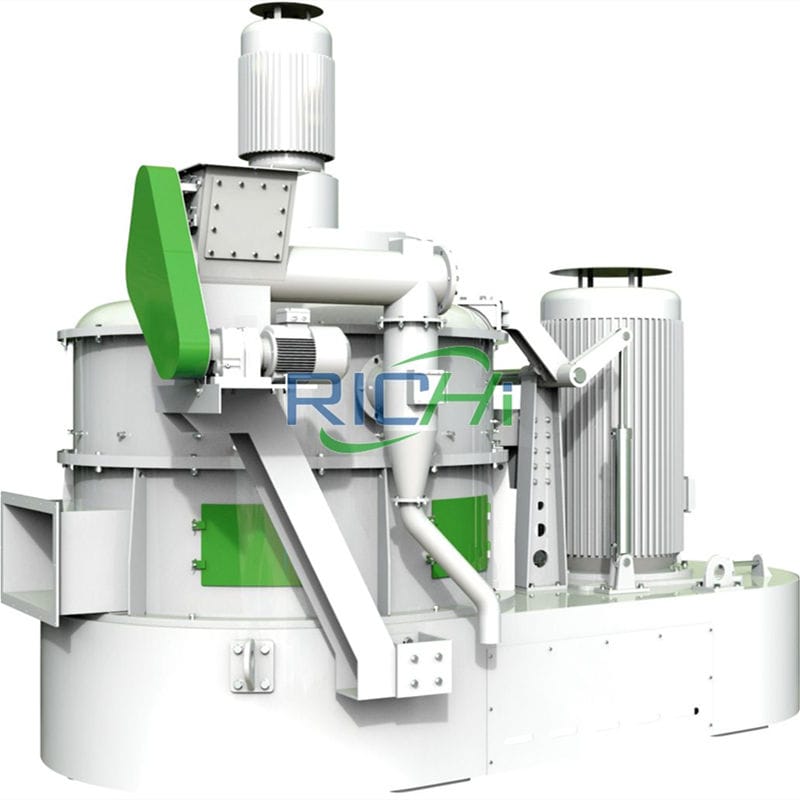

Equipment for Floating fish feed production line

Generally speaking, the core production equipment of a floating fish feed factory is hammer mill, ultrafine pulverizer, mixer, fish extruder, dryer, cooler, spraying machine, screening machine, packing scale, etc. The selection of equipment plays a vital role in feed production and ensuring feed quality.

Fish Feed Grinder

Fish Feed Mixer

Ultrafine Grinder

Fish Feed Dryer

Advantages of extruded pellet feed

The extruded pellet feed is loose in texture and has a porous structure. The extruded pellet feed can float on the water surface for a long time, which is convenient for the breeder to observe the feeding situation of aquatic animals.

Adjust the feeding amount in time according to the amount of feed intake, and remove the excess feed out of the breeding pond to reduce the pollution of the feed to the water quality.

Extruded pellet feed is produced by fish feed extruder and floating fish feed production line. During processing, the materials are processed under high temperature, high pressure, and high shear. On the one hand, some harmful fungi and toxins in the raw materials are killed or destroyed, and on the other hand, the structure of the materials changes.

Therefore, after extrusion, the starch and protein in the raw materials are easily digested and absorbed by fish and shrimp. Extruded pellets are more stable in water and not easy to collapse and lose.

Floating fish feed production line business plan

FAQ

The 10 tons per hour floating fish feed production line in Australia we configure usually costs between 200,000 and 2.5 million US dollars. According to the different scheme design and equipment configuration, the price varies greatly. Please contact us directly online, we will customize your fish feed manufacturing plant according to your raw materials, formulations, solutions and special process requirements.

The 2 tons per hour floating fish feed machine plant is usually between US$80,000 and US$400,000. Regarding the transportation price, you can directly consult our customer service staff online to obtain an accurate quotation.

According to your process requirements, the total price of the equipment is generally before 80,000 to 150,000. Regarding the freight, you can directly contact us online to obtain real-time sea freight prices.

Yes, we supply both floating fish feed machine and sinking fish feed machine. Floating fish feed usually adopts extruded feed process, while sinking fish feed can adopt traditional pelleting process or extruded process.

Depending on the process, the equipment configuration is also different. Please contact our technical consultants directly online to customize your process plan and equipment list.

The price of 1 ton floating fish feed making line is usually 30,000-150,000 USD. According to your needs, we can also provide custom design services.

The 2-3t/h floating fish feed line cost is USD 80,000-500,000. If you want to confirm the shipping cost, you can tell us the port where the equipment will arrive.

The 12t/h complete aqua feed production line cost is usually between 900,000-2.5 million US dollars. For more details, please contact WhatsApp:+86 138 3838 9622

In order to calculate the capacity of the floating fish feed production line, we also need to know the quantity of fish you breed, or you can provide the area of the fish pond for our engineer to calculate and provide you with the corresponding production line quotation.

The 3-4 tons per hour fish feed production plant price is usually between US$90,000 and US$600,000. We have had a lot of experience in process design and equipment processing of floating fish feed production plant. If you want to customize your production line, please contact us directly online.

The price of 4-5 tons of floating fish feed production line is usually before 135,000-900,000 US dollars. We have exported feed equipment to Latin American countries such as Ecuador, Peru, Chile, Argentina, Dominica, Honduras, Costa Rica, Guyana and Cuba.

The fish feed factory price of this capacity is between 140,000 and 1.2 million US dollars.Regarding the shipping cost, you can directly contact our customer service staff online to obtain the latest shipping quotation.

The 20 ton floating fish feed production line is a large-capacity feed processing system, which is relatively complicated and involves various processes and plant layout issues. Generally speaking, the production line price of this output is more than 2 million US dollars.

For the construction of a complete feed production line, we will closely track the progress of the project from the customer consultation stage to process design, equipment processing, installation, and commissioning to support customers.

This is a combined feed production line, that is, two or more feeds are processed in one production line. Before providing a quotation, we need to know some questions, such as:

Are the two feed processes the same? Does the poultry feed also adopt the extruding process? What are the required quantities of floating fish feed and poultry feed? …

There are many possibilities for this type of production line, depending on the requirements. Because, our technical consultants need to communicate with you further, so as to configure the floating fish feed production line that really suits you. (For more details, follow us on YouTube)