Aqua feed Production Business Guidance

Our aqua feed mill plant business guidance help you produce top quality fish shrimp feed and to make economical use of your raw materials and energy. As a technology partner with long-lasting experience in the industry, we support you in every aspect of the production of reliable aqua feed.

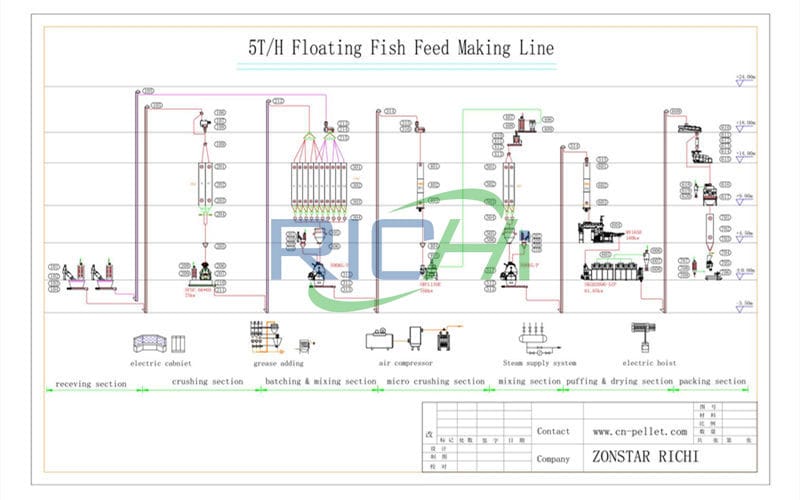

3-4T/H Floating Fish Feed Mill

The customer of this 3-4t/h floating fish feed mill project is the first time to contact the aquatic feed processing industry.

- Scale: 8,000t/a

- Investment: 600,000 USD

- Employees: 11

- Working system: 8 hours per day, 300 d/a

- Process design: batching-crushing-mixing-superfine pulverization-mixing-expansion-drying-cooling-packaging

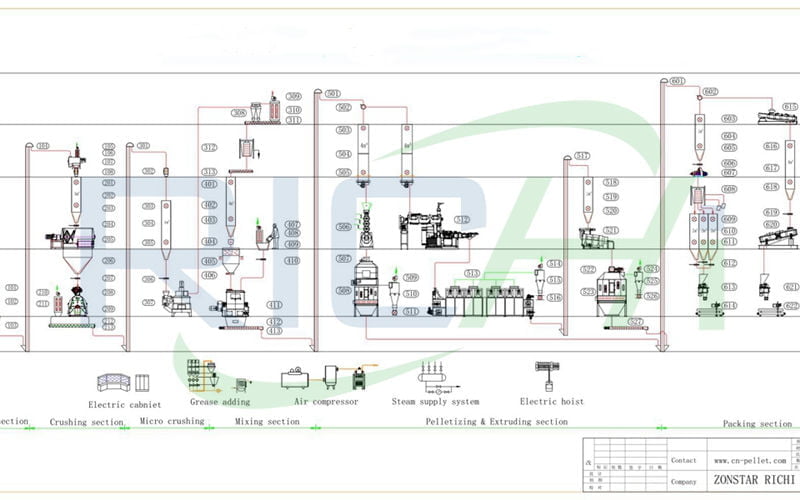

4-5T/H feed pellet production line

Customer has his own comprehensive compound feed factory. Due to the good operating conditions, the customer intends to expand production, because the competition of feed enterprises is the competition of cost and scale.

- Scale: 30,000t/a

- Investment: 1.6-1.7 million US dollars (including equipment and all other costs)

- Working system: 24 hours per day, 300 d/a

- Raw materials:Flour, Corn, Soybean meal, Rape meal, Peanut bran, Fish meal, Fat (soybean oil), Premix, etc.

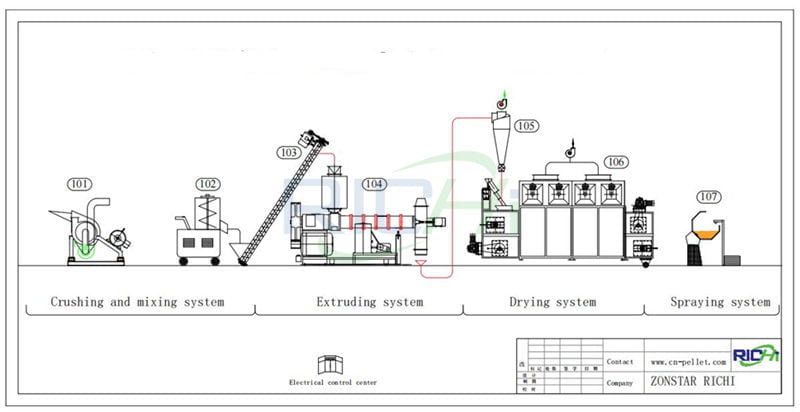

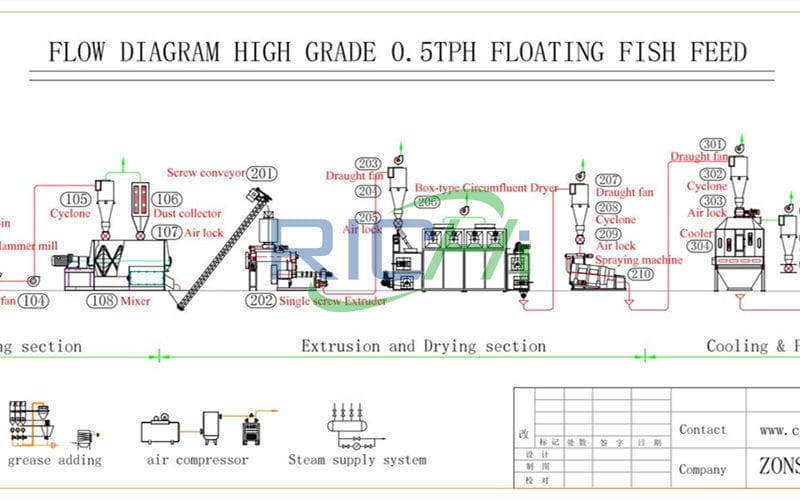

500KG/H Fish Food Processing Line

Since it is the first time to enter the aquatic feed industry, the initial investment is not large. It is worth mentioning that the customer did not let us design this small production line into a simple equipment configuration, and reserved the possibility of expansion.

- Capacity: 1200t/a

- Design: Using pelleting process and extruding process respectively to produce sinking feed and carp extruded feed;

- Steam supply: 2t/h steam boiler, gas consumption 98,000 m³/a;

- Total cost: 100,000 USD

- Working system: 300 days a year, 8 hours a day

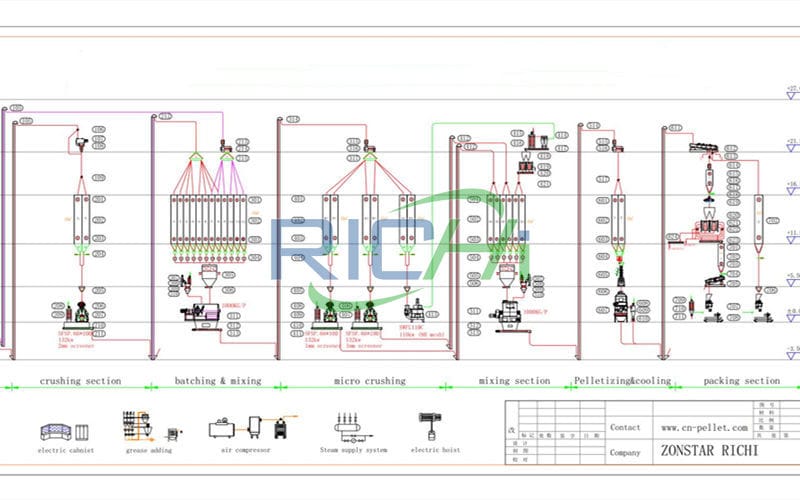

5T/H Aqua Feed Plant

The aqua feed production project is located in the customer’s existing factory area, and no new land is required. After the project is completed and put into operation, it can form an annual production capacity of 25,000 tons of aquatic feed.

- Product type: fish and shrimp feed

- Raw materials: corn, soybean meal, flour, peanut bran, rapeseed meal, barley, fish meal, soybean oil, fish oil, lecithin, etc.

- Process design: crushing, mixing, extrusion, drying, cooling, screening, packaging and other processes to produce the final finished aquatic feed.

6T/H Aquatic Feed Mill

The client is mainly engaged in the production and sales of livestock and poultry, fresh water and special water feed. In order to expand and stabilize the market share, he invested $4 million to add an extruded feed production line to the existing feed workshop.

- Scale: 25000 t/a

- Working hours: 10 hours per day, 200 days per year

- Raw mterials: Barley , Corn, Wheat middlings, Rice Bran, 43% soybean meal/46% soybean meal/45% soybean meal, Cottonseed Protein/50% Cotton Meal, Rape meal, Peanut Meal, Corn Gluten, 30% cornstarch residue, Imported fishmeal, etc.

4T/H Aqua Feed Mill

The customer’s original products are mainly poultry and pig feed, fish feed pellets, etc. In order to adapt to changes in market demand and increase the diversity of feed products, the customer invested 220,000 US dollars in the expansion of original project and product structure.

- Scale: 10,000 tons

- Total Water Consumption: 9270.2t/a

- Total Electricity Consumption: 13.3 million kWh/a

- Total Gas Consumption: 1.16 million m³/a

- Raw materials: Peanut Cake, Flour, Rapeseed Cake, Rice bran, Wheat germ, Soybean oil, Fishmeal, Puffed Soybeans, etc.

500KG/H Fish Food Production Line

The type of feed processing chosen by the client for this 500kg/h fish food production line project is the development trend of the feed industry in the future – diversification of categories, not just one kind of feed. Especially for livestock and poultry feed factories.

- Capacity: 10,000t/a, including 500kg/h of fish feed;

- Investment: 120,000 US dollars;

- Main raw material: Soybean meal, Rapeseed Meal, Fish meal, Additives, Other raw materials.

- Procee design: including crushing process, mixing process, pelleting process, dust collection system, etc.

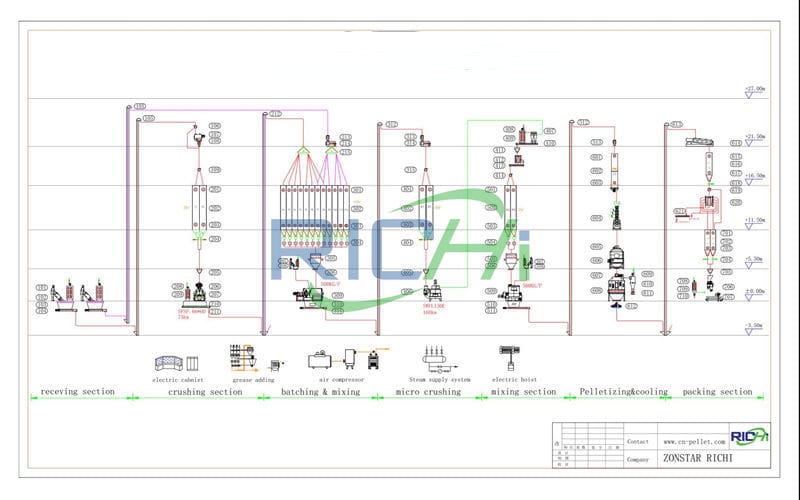

8T/H Floating Fish Feed Plant

The development of the fish feed production industry has significant economic and social benefits. Therefore, the client of this project built a new fish feed production line with an annual output of 20,000 tons.

- Electricity consumption: 270,000 kWh/a

- Raw materials: corn, soybean meal, flour, rapeseed meal, peanut bran, vegetable oil, etc.

- Process design: Material receiving, Grinding, Mixing, Secondary crushing, Secondary batching, Extrusion, Drying, Spraying, Packaging.

- Boiler type: Biomass boiler 6t/h

6T/H Fish Feed Mill Plant

The client of this project invested 2 million US dollars to build an aquatic feed production project. Mainly build a production line with 3t/h compound sinking fish pellet feed and a production line with 3t/h extruded fish feed.

- Scale: 7500t/a

- Production system: 8 hours a day, 300 days a year

- Investment: 2 million US dollars

- Main equipment: aquatic feed extruder, fish feed pellet machine, grease sprayer, feed grinder, mixer, screening machine, packaging machine, etc.

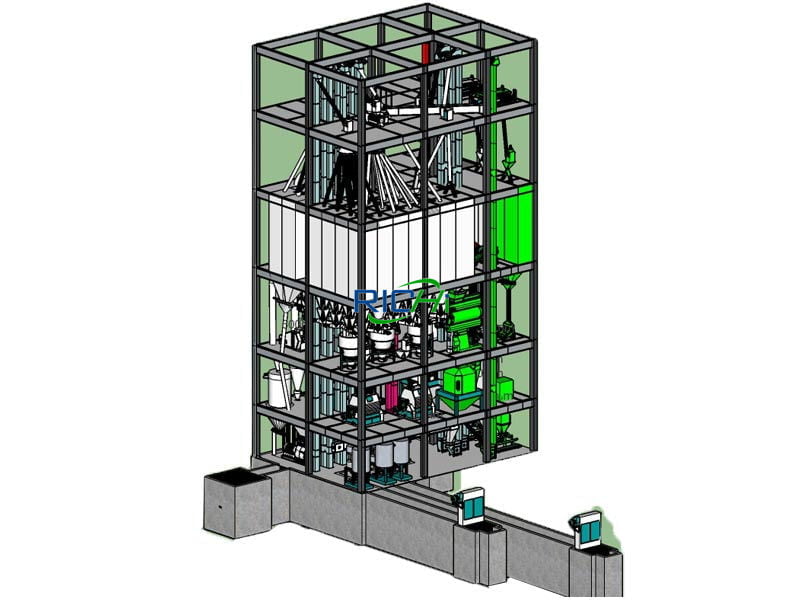

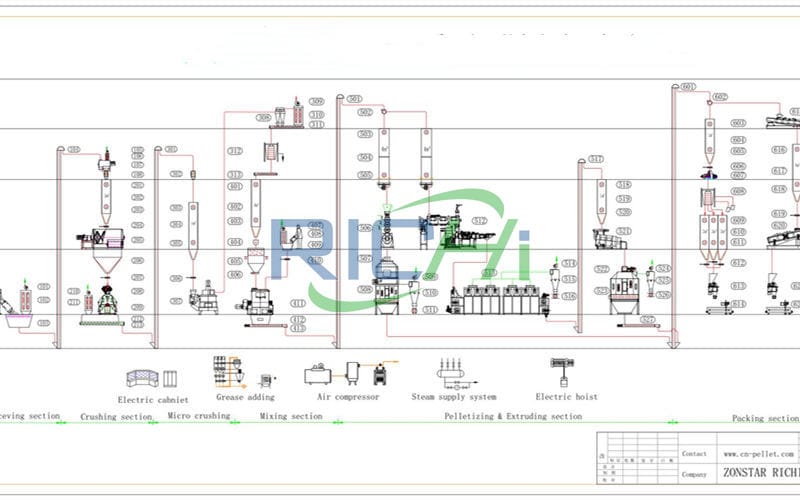

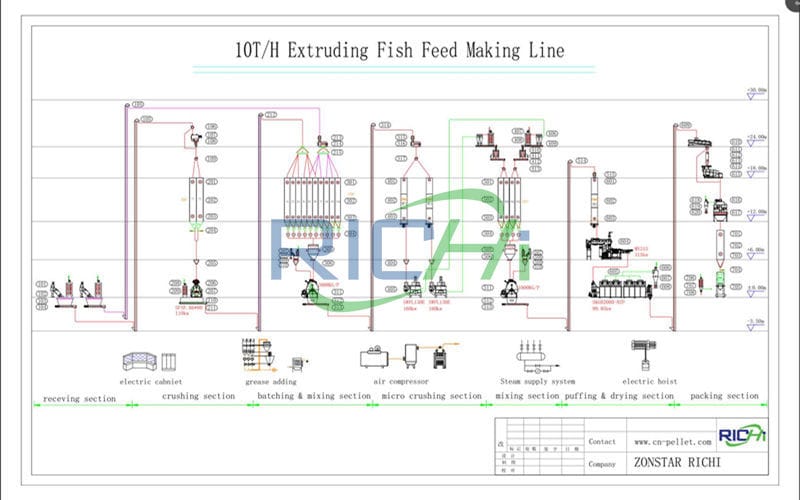

10T/H Fish Feed Manufacturing Plant

This project is a typical example of a livestock and poultry feed factory getting involved in aquatic feed processing. In order to meet the needs of the market, the company adjusted its development strategy in a timely manner and planned to implement a reconstruction project.

- Capacity: 70,000 t/a

- Cost: $1.6 million

- For extruded fish feed, pelletized fish feed, pig feed and concentrated feed

- Raw materials:Soybean meal, Corn, Rape meal, Flour, Fish meal, Additives (lysine, etc.), Soybean oil, etc.

- Annual gas consumption of the boiler (10,000 m³ /a): 4.8

18T/H Shrimp & fish feed factory

This is an example of a composite project of extruded fish feed factory, shrimp feed factory, fermented raw material, and fermented feed factory. It includes the production of 2 t/h shrimp feed and 16 t/h fish feed. The project took 8 months from design to installation.

- Capacity: 135,000 t/a

- Cost: $7 million (including civil works)

- Product Type: extruded fish feed, shrimp pellet feed, fermented feed and poultry livestock feed

- Boiler: 15t/h biomass-fired steam boiler

- Soybean Meal, Corn , Flour, Chicken powder, Fish meal, Squid Cream, Other additives (mainly salt, lime powder, flavors, amino acids, vitamins, etc.), Grease, Rice Bran, etc.

20T/H fish feed production plant

In order to meet the market demand, the customer company invested an additional US$1 million to expand the existing factory area. After the expansion, 50,000 tons/year of special aquatic extruded feed was added, and the original 30,000 tons/year livestock and poultry feed production line remained unchanged.

- For floating fish feed and livestock feed production

- Water Consumption: 1838.45m³/a

- Electricity Consumption: 800,000 KWh/a

- Raw materials: Corn, Wheat Bran, Rape Meal, Cotton Meal, Soybean Meal, Rice bran meal, Calcium Carbonate Powder, Fishmeal, Grease, Salt, Wheat middlings, Vitamin Supplements, Amino acid additive, etc.

25T/H aqua feed production line

The client invested 8 million USD (including civil engineering) to build a new production plant and its auxiliary facilities in the existing factory area, with a total construction area of about 14,000m². After the project is completed and reaches its full capacity, it can form an additional production capacity of 190,000 tons of compound feed such as prawns, crabs, and lobsters.

- Working System: production in three shifts, 8 hours per shift, 312 working days per year;

- Steam Consumption: 28,000t/a;

- Water Consumption: 60744.66t/a.

- Raw materials:Corn, Wheat, Additives, Soybean Meal, Rape Meal, Flour, Peanut Meal, Fishmeal, Chicken Powder, Grease, Hydrochloric Acid, PAC, PAM, etc.

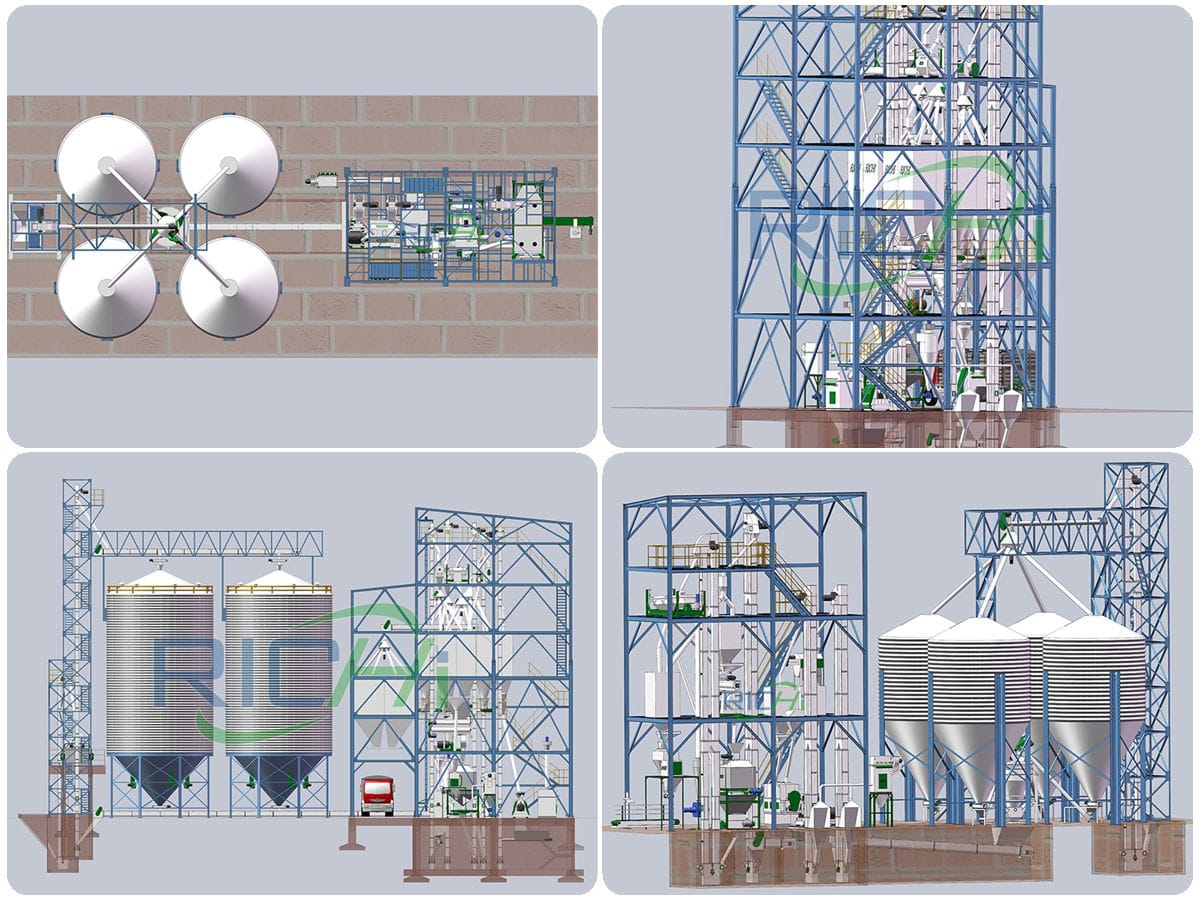

40-42T/H Aqua Shrimp Crab Fish Food Factory

This is a large-scale aquatic shrimp crab fish food factory project (including the processing of aquatic feed such as fish, shrimp and crab extruded feed, submerged pellet fish feed, shrimp and crab mixed feed). The total production capacity is expected to reach 100,000 tons.

- Construction nature: newly built;

- Occupied area: 38721 m²;

- Total investment: 20 million US dollars (including all civil construction).

- Electricity: 11.1 million kwh/a

- Water: 35070m³/a

- Gas: 2.022 million Nm³/a

- Working system: 8 hours, and the annual working day is 300 days.