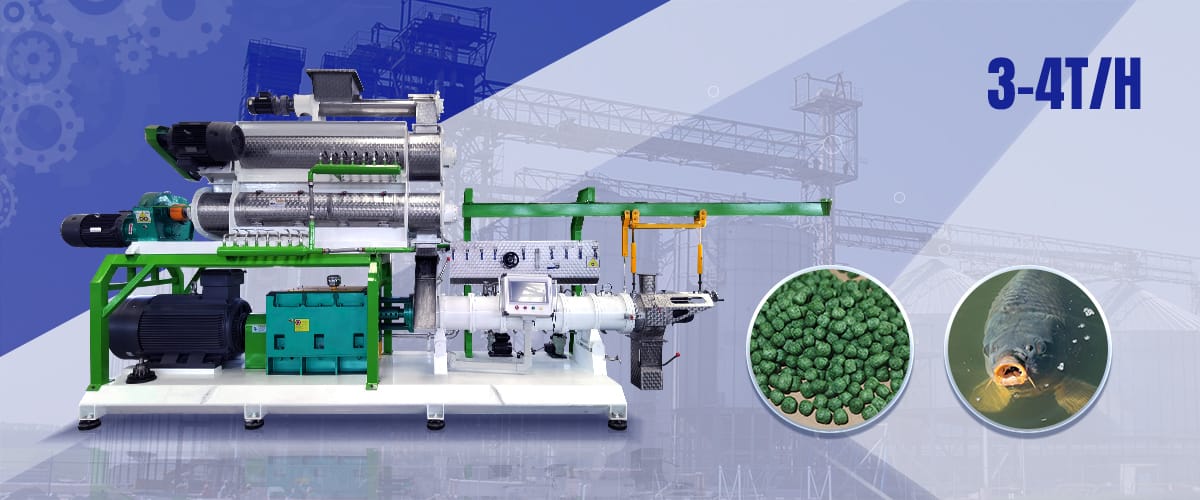

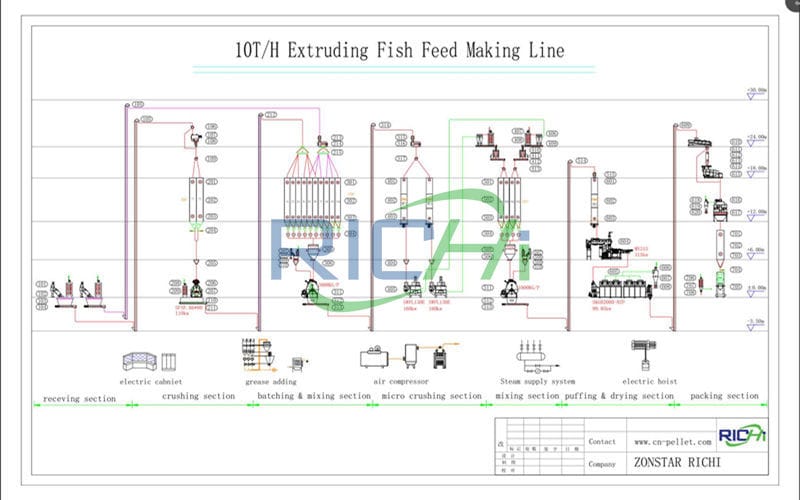

RICHI’s new type RCPH185*2 fish feed pellet extruder is a twin-screw type extrusion equipment, its power configuration is 315KW, and the output of processed aquatic feed is from 8-10 t/h.

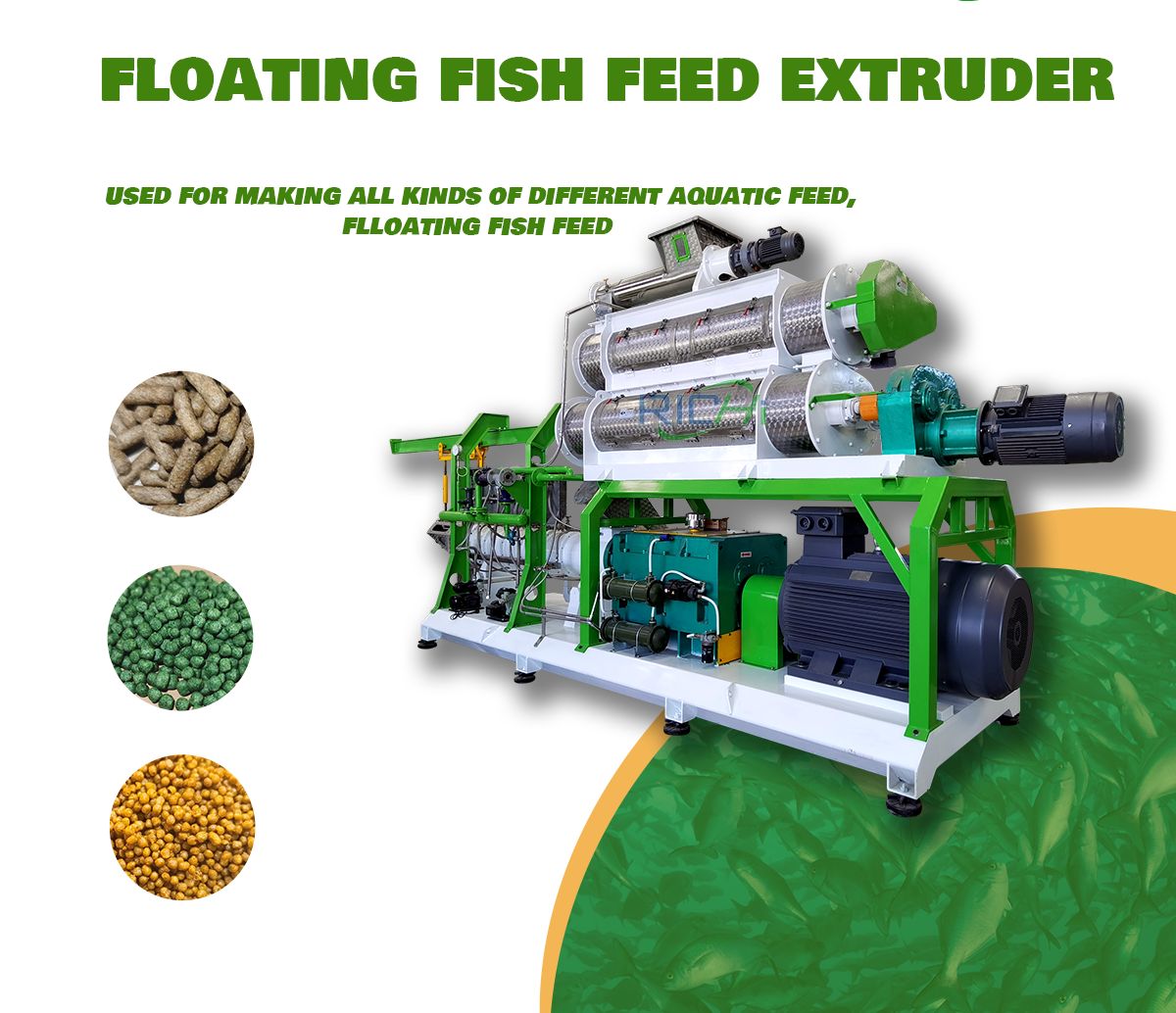

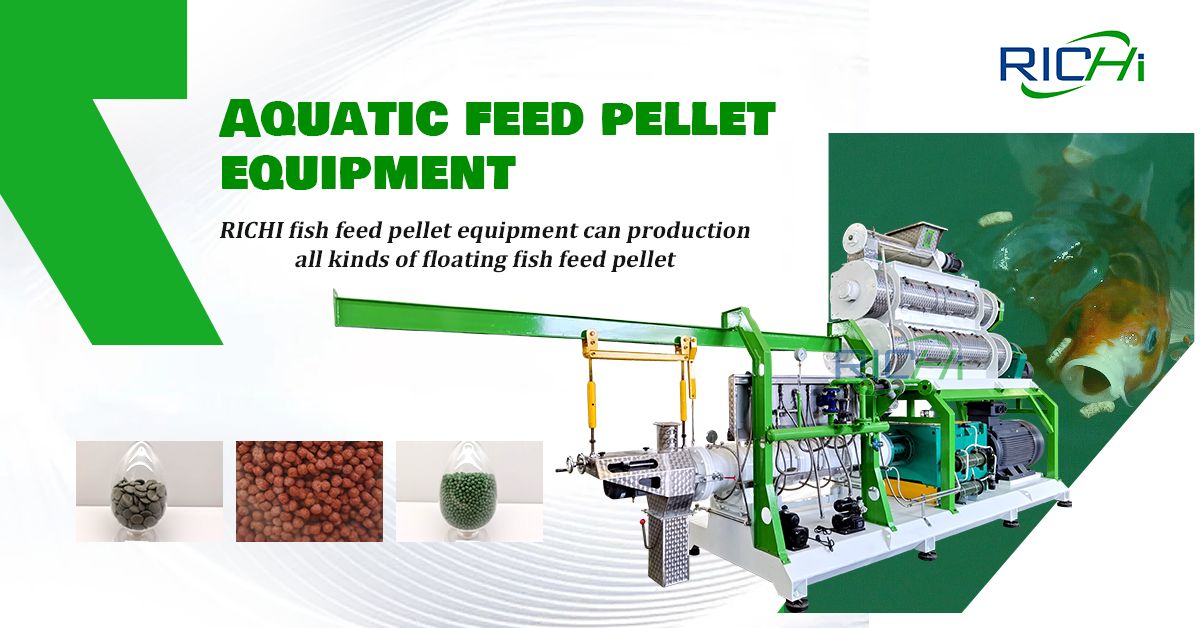

RICHI fish pellet extruder series can ensure the extruded pellet feed you are producing has the right properties, giving it the appropriate attributes necessary to deliver the feed to the correct location in the water.

In addition to medium and large-scale aquatic feed processing (floating feed, slow-sinking feed, fast-sinking feed, high-oil content feed, wet feed, etc.), this equipment is also suitable for plant tissue protein and snack foods, nutritious food and other production needs in various pet feed and food industries.

- Capacity: 8-10T/H

- Type: twin screw

- Application: large aqua feed plant, grain factory, pet food factory, poultry livestock feed plant, etc.

Video of 8-10 t/h fish feed pellet extruder

8-10 t/h fish feed pellet extruder Specifications

| NAME | MODEL | QTY | POWER(KW) |

| Anti-caking bin | PGS900/800 | 1 | 2.2+0.3 |

| Inverter feeder | WLQ219-1300 | 1 | 2.20 |

| Conditioner | DC600/300 | 1 | 15.00 |

| DDC-conditioner | DDC500/300-300 | 1 | 15.00 |

| Pellet extruder | RCPH185*2 | 1 | 315.00 |

Advantages of fish feed pellet extruder

- High degree of processing flexibility

- User-friendly design for operation and maintenance

- Minimum downtime

- Integrated operating systems resulting in reduced installation time and costs

- Low maintenance/wear part costs

- Enclosed design with hygiene, ease of cleaning, and access to operating systems in mind

- Wide variety of options and accessories available to meet specific requirements

Technical characteristics of 8-10 t/h fish feed pellet extruder

The equipment has a high-precision expansion chamber, high-precision gears, imported high-quality bearings, oil seals, advanced gearbox design and processing technology control technology.

- The main engine of the fish pellet extruder adopts frequency conversion main motor, and the transmission system is strong, stable and reliable;

- The heating and cooling layer of the barrel is an integral forging structure, and the inner sleeve of the barrel and the screw element are made of high wear-resistant alloy steel;

- The template adopts new materials and scientific hole layout technology;

- The quenching and tempering system adopts an extended stainless steel double-shaft differential speed conditioner, which has a reasonable structure and beautiful appearance;

- PLC+touch screen control system are adopted, high degree of automation;

- The new fully wear-resistant alloy (38CrMoAi) screw and the inner sleeve of the bimetal expansion cavity can effectively reduce the wear and tear and ensure the long-term stable operation of the floating fish feed machine under the condition of high production capacity and high quality;

- The cutting part adopts a movable cutter seat, and the blade is made of spring steel, which fits well with the template. The cutter is driven by a frequency conversion motor, which can control the length of the product;

- The turbulent discharge device discharges the material to make the extruded puffed material more beautiful.

8-10 t/h fish feed pellet extruder price

8-10 t/h fish feed extruder cost: 190000 – 210000 USD

The technical performance of this equipment has approached or basically reached the level of twin-screw feed pellet extruders of internationally renowned brands, but its price is only one-third to one-half of the price of imported products, providing feed and food processing enterprises in various countries It is a cost-effective twin-screw extrusion equipment with low price and perfect performance.

fish feed pellet extruder and fish feed plant case

Whether it is in the traditional markets of China and Asia, or in the emerging markets of Latin America and Africa, RICHI has rich experience in aqua and pet feed pellet extruder processing and aquatic extrusion feed processing line construction.

1.5-2T/H

1.5-2T/H Twin-screw Floating Fish Production Line & Shrimp Feed Line In Iran

1.5-2T/H

1.5-2T/H Floating Fish Feed Machine Plant In Russia

1T/H

1T/H Floating Fish Feed Mill Plant & 2*5-7T/H Poultry Feed Plant In Zimbabwe

How to choose a 8-10 t/h fish feed pellet extruder?

Aqua feed mill customers often ask these two questions: For dry extrusion or wet extrusion, single-screw extrusion or twin-screw extrusion, which one is better? There is no definite answer to this question. The best answer is to look at its practical application. As far as the nutritional quality of the extruded feed is concerned, wet extrusion and twin-screw extrusion are better choices, especially for slightly larger feed mills.

Each method can produce high-quality feed if the processing conditions and process controls used are appropriate.

For those fish feed mills who want to try extrusion technology, the first issues to consider before making a decision are: what kind of extruded feed to produce, financial situation, personnel and skills required for extrusion operation and maintenance, and the cost of extruded feed. Market demand and development planning of aqua feed mills, etc.

After making a decision to purchase an extruder for fish feed, the feed mill must understand the following details of the fish extruder: type of aqua feed extruder, production capacity, adaptability of the floating feed extruder, operation of the floating pellet extruder, original cost, operating cost, capital turnover space, maintenance and repair costs, training programs, technical support programs, customer service programs and sales systems, etc.

Processing requirements for 8-10 t/h fish feed pellet extruder

The external adjustments in the extrusion process are mainly moisture, temperature, die hole area and screw speed.

Moisture

The holes in the extruded particles are left by the volume expansion of the water vaporization when the material exits the die hole. The size of the pores is related to the moisture content of the raw material, and the production of floating feed requires an appropriate moisture content of the raw material.

Temperature

The temperature of the screw chamber near the mold plate can be adjusted, and the temperature can be heated to promote the vaporization of the water, and the product density will decrease; the cooling water is used to cool down, reducing the vaporization intensity, and the product density is increased.

Die Hole Area

All materials become products through the die hole, and the die hole is the last passage of the material. The channel area is large, the material can pass through at a relatively low pressure, the pressure difference between the inside and outside of the formwork is small, and the degree of material vaporization is low.

The template with more die holes is used for the production of sinking feed, and the template with less die holes is used for the production of floating feed.

Screw Speed

When the screw speed of the fish feed pellet extruder increases, the mechanical energy applied to the material will increase, thereby affecting the density of the product.

Using the same fish extruder with a fixed hourly output, it was found that the relationship between screw speed and product bulk density decreased with the increase of screw speed, that is, the selection of lower screw speed in the production of sinking feed was beneficial to increase the particle density.

Why use fish feed pellet extruder to process feed?

Compared with pellet feed produced by other processing methods, the pellet feed produced by extruding processing has the characteristics of general pellet feed—good palatability, avoiding feed grading, easy storage and transportation, convenient feeding and reduced animal feeding process. In addition to reducing feed waste, etc., it also has the following advantages:

- The gelatinization of starch in the feed is relatively complete, and generally its gelatinization degree can reach more than 90%. The gelatinized starch has a greater water absorption capacity, and the starch changes from water-insoluble to water-soluble, which can accelerate the enzymatic hydrolysis process of starch, thereby improving the digestibility of feed;

- It has continuous and stable floating characteristics and stability, thereby reducing water pollution and feed waste. At the same time, slow-sinking feed and sinking feed can also be produced by extruding processing method;

- The feed undergoes high-temperature and high-pressure instant puffing treatment, resulting in beneficial physical and chemical changes. The anti-nutritional factors contained in the bean cake are destroyed, and at the same time, it can also passivate the naturally occurring toxins and kill harmful microorganisms, which is beneficial to the digestion and absorption of animals. Improve the conversion rate of feed, so that the expensive animal protein can be replaced by plant protein, and the cost of feed can be reduced;

- Extruded extruded feed can produce pellets of various shapes by changing different templates;

- Can make full use of the lowest cost formula to reduce feed cost. Of course, extrusion expansion will also have some adverse effects, especially for a class of heat-sensitive components (such as vitamin C, etc.) with greater damage and loss;

- Excessively high temperature will also destroy some amino acids, thereby reducing the nutritional value of protein. Therefore, the addition of microorganisms in extruded feed is generally carried out after extrusion.

Similar floating fish pellet extruder products

To meet the ever increasing demand from fish feed and pet food producers for high-capacity feed extrusion plants, RICHI has developed a generation of high efficiency fish feed pellet extruders.

10-12 T/H Fish Food Extruder Machine

Working Principle of 8-10 t/h fish feed pellet extruder system

The material is extruded by a feed pellet extruder, and its compression ratio can reach 4-10. At the same time, the movement of the material in the extrusion chamber is accompanied by strong shearing, kneading and friction, and sometimes the partition wall of the material can be heated by the water vapor flowing through the jacket of the barrel as needed.

As a result of such joint action, the temperature of the material suddenly rises (110°C-200°C), the starch in the material is gelatinized immediately, and the whole material becomes a molten plastic jelly.

At this time, although the temperature of the moisture in the material is very high, the moisture is generally not transformed into water vapor under relatively high pressure.

But when the material is discharged from the formwork, as the pressure suddenly drops to an atmospheric pressure, the volume of the material expands rapidly, and the moisture content of the material decreases as a result of further evaporation and removal of water vapor.

At the same time, due to the rapid drop in temperature, the gelatinized starch coagulates immediately, and the dispersion of water vapor leaves many micropores in the coagulated colloidal material, thus forming the so-called extruded feed.

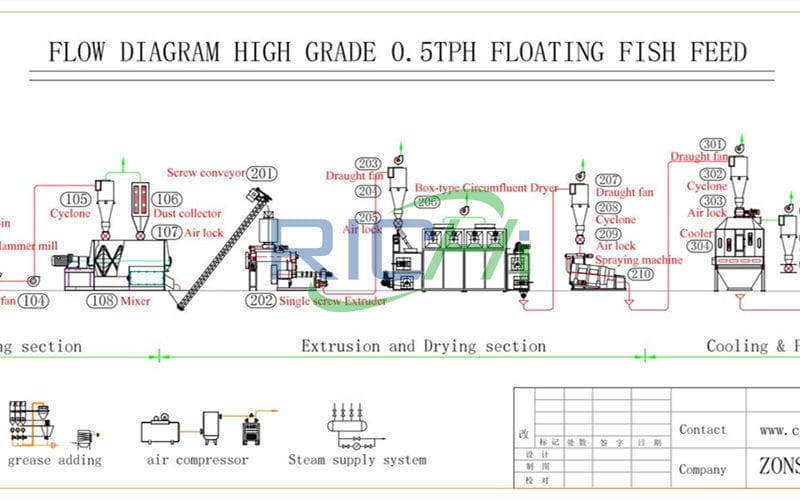

However, the material extruded from the fish feed pellet extruder, although part of the water can be removed during evaporation and subsequent transportation, the water content in the material is still high (usually higher than 20%), so it must be dried , and then cooled to reduce the moisture content of the material to about 13%, and then crushed, sieved, and sprayed to obtain the required puffed pellets.

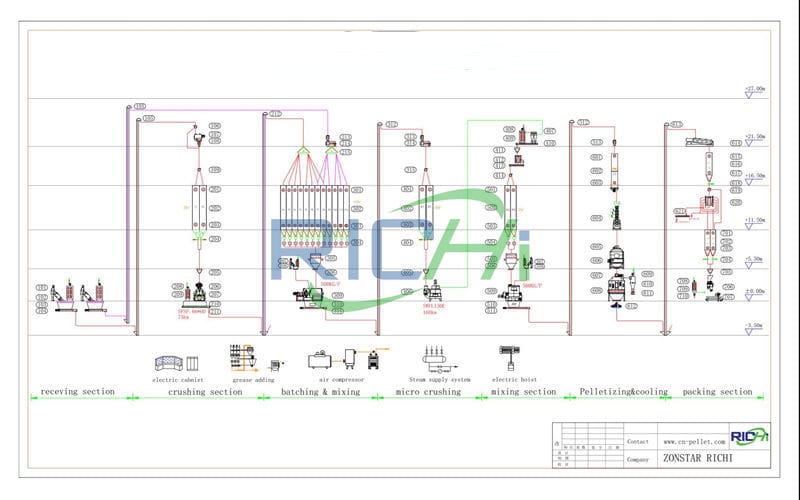

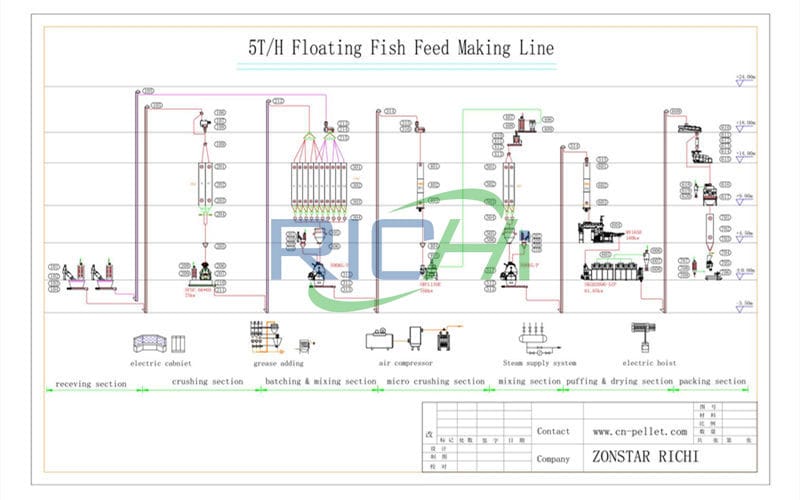

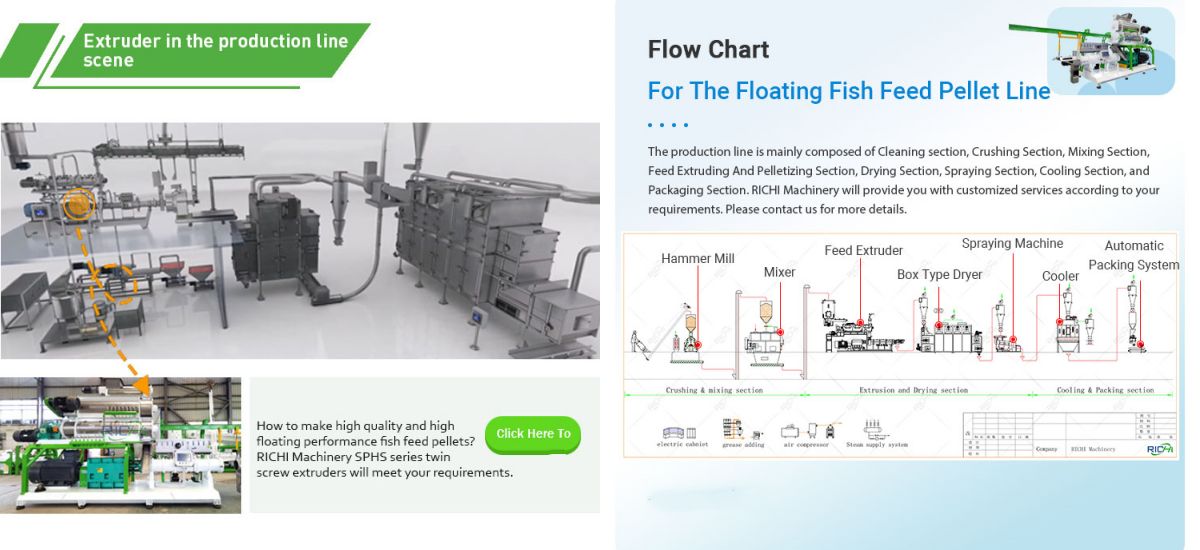

It can be seen that the fish feed pellet mill extruder is only the core equipment for producing extruded feed, and other processes and equipment are needed to work together to finally process it into an ideal extruded feed product.

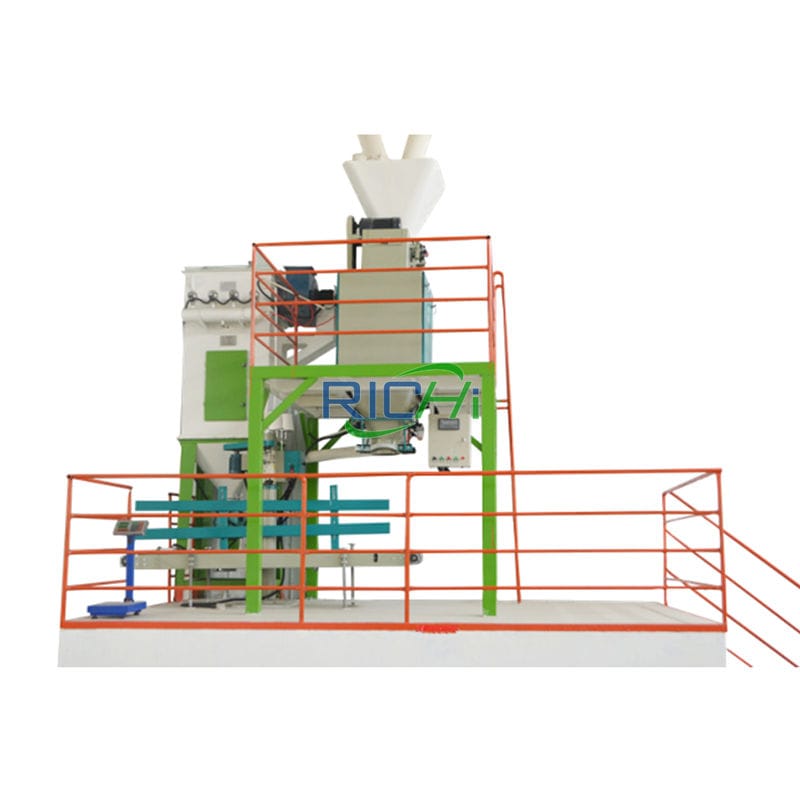

Supporting equipment:

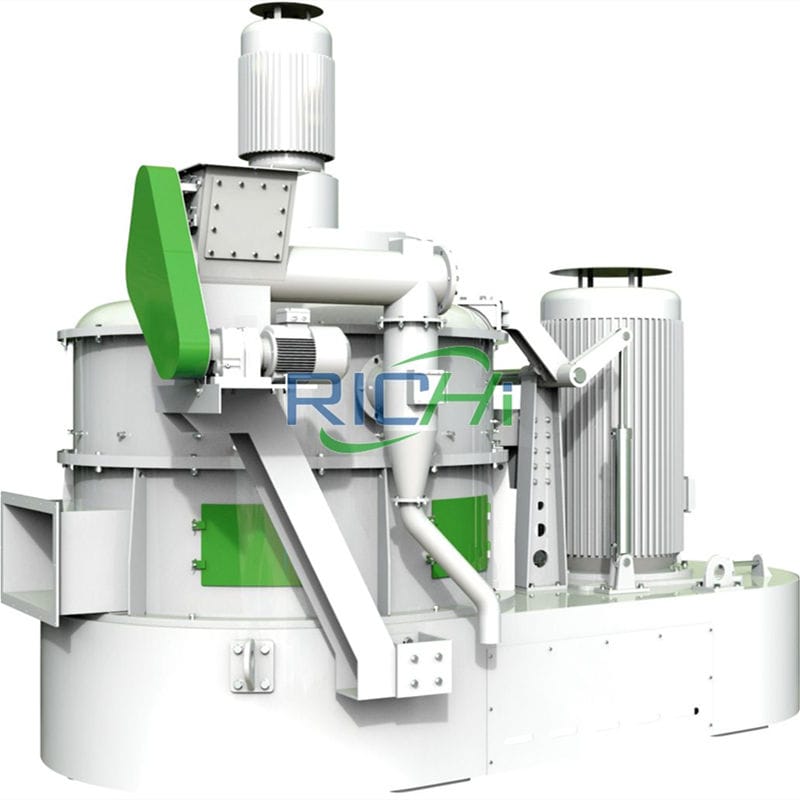

Fish Feed Grinder

Fish Feed Mixer

Ultrafine Grinder

Fish Feed Dryer

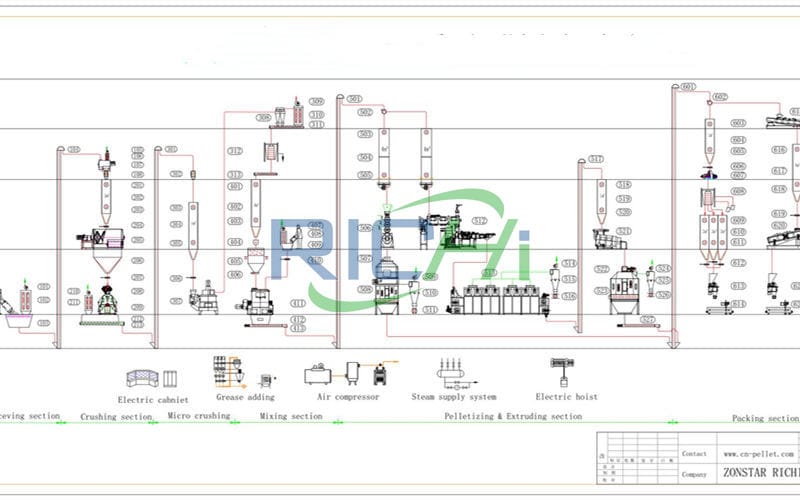

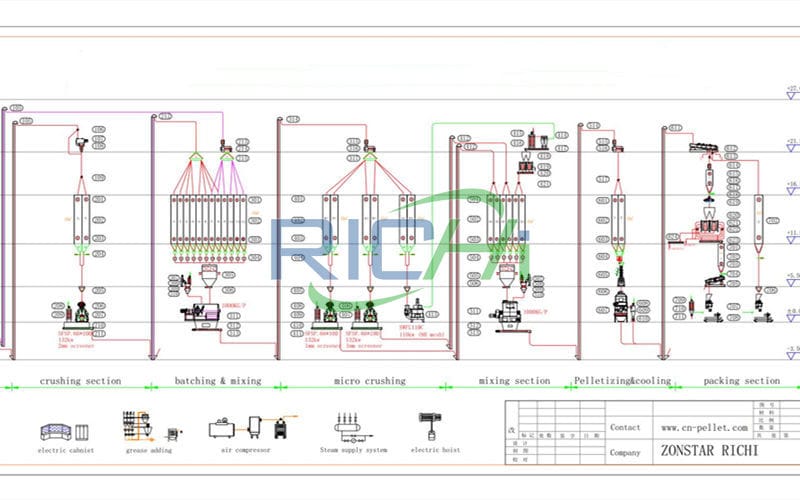

Complete set of floating fish feed production line plan

RICHI MACHINERY have the skills and experience to define the best fish shrimp aqua feed production solution, making us the perfect partner at every stage of your project, from initial design to completion as well as maintenance for the lifetime of your aqua feed plant.

Application of extruded feed in aquatic products

The advantages of extruded floating fish feed are very suitable for modern aquaculture industry and have good market potential. Therefore, at present, the majority of feed manufacturers are developing and developing puffed floating feed varieties, including medium and high-grade varieties suitable for cage culture, and medium and low-grade varieties such as tilapia widely raised.

At the same time, each fish feed factory is constantly improving formula quality and fish feed pellet extruder production process, expanding production scale, reducing production cost and improving feed quality. And through experiments and extensive publicity, the majority of aquaculture farmers try and use puffed floating fish feed.

- Floating aquatic feed: the density ranges from 320 to 400kg/m3. The particle diameter is 1.5-100 mm. The moisture content during puffing is about 24% to 29%, and the puffing rate is 125% to 150% of that when the feed is molded.

- Sedimentation aquatic feed: the density ranges from 400 to 600kg/m3, the diameter is 1.5 to 4mm, and the moisture content is about 22% to 25% during puffing. This feed is mainly used to feed animals that are slow to feed at the bottom of the water. Therefore, the feed is required to remain in the water for 2 to 4 hours without disintegration, so that the animals have sufficient time to eat.

- Slow-settling aquatic feed: the density ranges from 390 to 410kg/m3. This is the range of sedimentation in salt water. Product particle size affects its density. Therefore, to produce this kind of feed, the feed density of each formula must be calculated accurately.

- Soft and moist feed: The production scale of this product is small. It has been found through research that some aquatic animal species only eat soft feed and do not eat hard pellet feed. Its moisture content requires 30% to 32%.

In short, extrusion expansion can meet the special needs of some customers. If the pellet feed made by fish feed pellet extruder is required to sink at various speeds, or the pellets are required to float, or even to be made into pellet feed that repeatedly sinks and floats, it can first float in the water, then sink, and then float up again after a short time.

Feed raw materials are the guarantee of final product quality, which requires formula designers to choose good raw materials. For example: in order to ensure the stability of the feed in water: the starch content of the sinking aquatic feed should be at least 10%, while the floating feed should be at least 20%. Increasing the starch content will increase the puffed density of the puffed product.

Under the puffing process, the sinking aquatic feed will hopefully “puff” 10%-15% beyond the die hole, and the floating feed will puff at least 50% larger than the die hole. In addition, the amount of starch required to achieve the desired puffed density of the extruded feed is also affected by water solubility and puffed proteins in the formulation. The presence of these functional proteins will improve puffing and binding properties and will reduce the level of starch required.

About Us

Richi Machinery is a professional aqua feed machine factory integrating scientific research and development, manufacturing, sales and service. In the past 30 years, RICHI has focused on the R&D, production and system performance improvement solutions of aquatic feed machinery such as fish feed extruders, fish feed pellet machine, shrimp feed pellet machine, pulverizers, dryers, and sprayers. So far, thousands of aquatic feed equipment have been newly installed for customers around the world, and more than 100 technical upgrades of aquatic feed production line systems have been provided. Build hundreds of aquatic feed production lines. (Find us on YouTube)