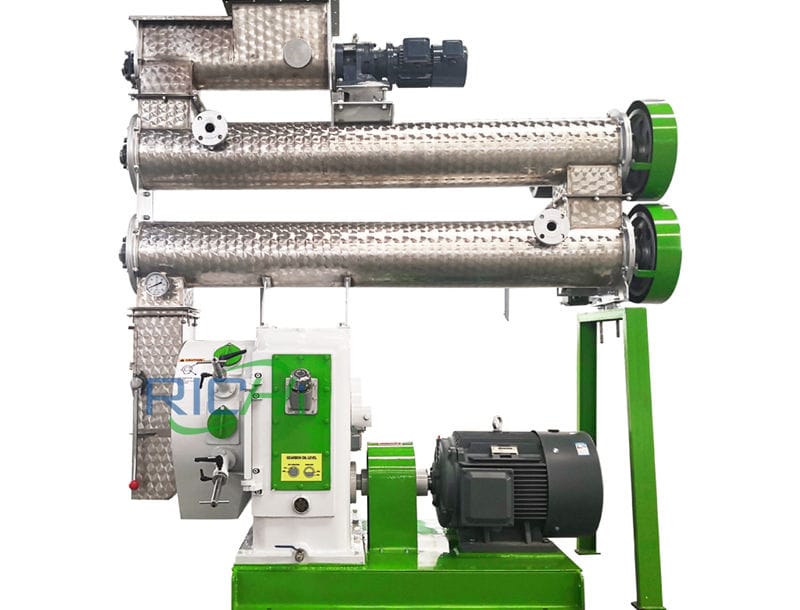

RICHI 1.8-2.4 t/h sinking fish feed pelleting machine is widely used, suitable for processing sinking catfish food, sinking koi pellets, sinking trout pellets, sinking goldfish food and other kinds of sinking fish feed.

Our fish feed pellet machine can be differentiated and customized according to user needs to achieve high-quality production. It can also customize a complete set of sinking fish feed processing system to provide customers with a full set of worry-free services from program customization to equipment manufacturing, installation, training and after-sales.

RICHI SZLH series fish feed pelletizing machine is used for granulation. The main advantages of this processing method to produce pellet feed for aquatic animals are high output, low investment in equipment, and the extruded pellet feed can be used as commercial feed after cooling and cooling without drying. .

Features of fish feed pelleting machine

The aquatic sinking fish feed pelleting machine requires the cutter mechanism to be fixed on the box body, which is convenient for observation and positioning, and there is no need to exit the cutter mechanism when opening the door cover.

The hole diameter of the ring die is generally φ1.5-3mm, and the length-to-diameter ratio is generally 1:10 -1:30 (can be changed according to user needs), the cutter is close to the outer surface of the ring die to ensure that the ring die can discharge the material at one time.

- RICHI fish feed pellets machine adopts modular design, which can perfectly adapt to the most diverse requirements;

- Double-layer or triple-layer granulation process in the smallest space ensures the highest pellet quality while improving performance and ensuring greater flexibility.

- RICHI sinking fish feed machine can be adjusted regionally and seasonally according to formula and production mode to ensure efficient production of fish feed;

- RICHI fish feed pellet machine adopts a high-strength ring die design, and the power per unit area is increased by 15%, further improving the quality of granules;

- Our feed pellet mill has precise moisture control and steam utilization design, which ensures the quality and production capacity of the fish feed pellet system;

- Our feed pelleting machine is equipped with an external liquid addition system, which is equipped with molasses and second fluid addition technology to meet different needs for liquid addition;

- Automatic design such as automatic lubrication and electric lifting is used, which greatly reduces labor costs and improves production efficiency;

In the process of sinking fish feed pellet production, the different operating conditions experienced put forward high requirements for construction and production.

That’s why the RICHI fish feed pellet machine is entirely made of high-quality materials and of course complies with the latest safety standards and guidelines. Depending on the type of machine and the field of application, the maximum capacity of the pellet machine can reach 27 tons/hour.

Parameters of fish feed pelleting machine

The fish feed pellet machine is mainly used to produce hard pellet feed, which is suitable for sinking aquatic animals and bottom living prawns and herrings. The small pellets made of it have a smooth appearance and are not easily corroded by water, which improves the stability of the particles in water.

| Model | SZLH250 |

|---|---|

| Capacity(TPH) | 1.8-2.4 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

Operating conditions of sinking fish feed pelleting machine

- Requirements Before Entering Pellet Machine: 1.0-2.0

- Pellet Diameter (mm): 2-6

- Pellet Length (mm): 4-12

- Ring Die Compression Ratio: 1:16—-1:18

- Conditoning Temperature (℃): 150

- Conditoning Time (s): 90-180

- Equipped Conditioner: two layer/three layer

If you want to know more parameters and corresponding quotations of the sinking fish pellet mill, you can click to inquire about the price, or leave us a message, and I will reply to you as soon as possible.

Optional scheme

- Optional double-layer or triple-layer conditioner system

- Automatic roller gap adjustment system

- Sound insulation system

- Electric door heating system

- Heat insulation system

- Press roller temperature control system

- Automatic central lubrication device forced feeder

- Hydraulic driven ring die lifting frame

- Special design for handling extremely light bulk materials

- Maintenance of drive system

- Pneumatic adjustable particle cutter head

- Customizable body color system

fish feed pelleting machine price

The fish feed pellet machine price is 7000-30000 USD. This kind of fish feed pellets machinie appeared earlier, so the production technology of each manufacturer is relatively mature, which can effectively control the production cost.

RICHI has been specializing in the production of aquatic feed pellet mills for nearly 30 years. The pellet mills produced are reliable in quality and excellent in performance. Various configurations are optional and customized.

No matter which country you are from, you are welcome to visit our factory workshop. If you want to get more detailed equipment quotations and equipment information, please consult online directly, Richi Machinery looks forward to serving you. (Maybe you are interested in:4t/h aqua feed mill)

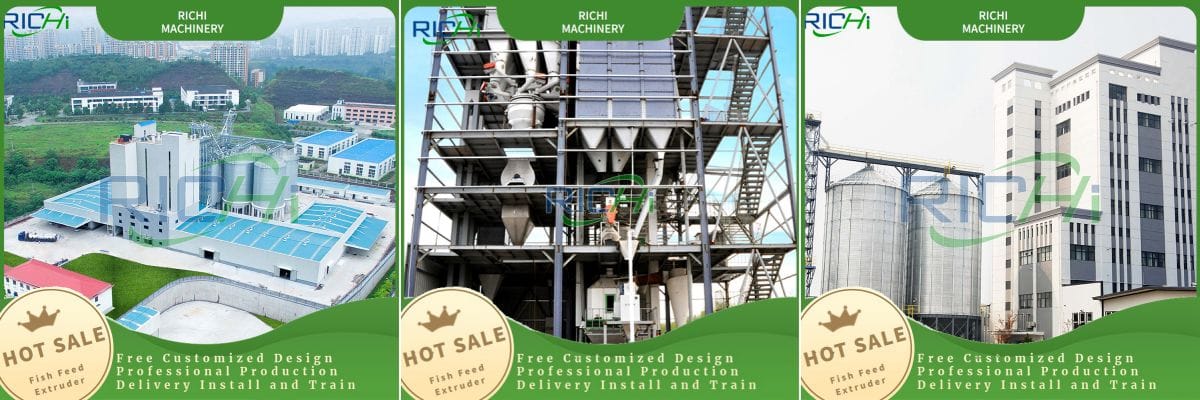

Fish feed pelleting machine project

Richi Machinery provides high-quality pellet mills and advanced complete fish feed mill plant solutions to global customers. We provide a full set of services from delivery—installation—operation—after-sales. Today, the marketing network of Richi Machinery has covered more than 130 countries and regions in Asia, Africa, Europe, America and Oceania.

As a member of the global aquatic feed equipment industry, Richi Machinery always adheres to technology and quality, dares to innovate, and pursues excellence.

Sinking Fish feed pelleting machine in Thailand

For a long time, Richi Machinery has always taken strong production strength as the cornerstone of development.

RICHI enjoys a high reputation in more than 130 countries and regions in the world, and has won the trust of many brands and well-known enterprises around the world with high-quality products and services.

fish feed pelleting machine Conditioner selection

How many layers of conditioner does the sink fish feed pelleting machine need?

- Generally speaking, the fish feed pellet mill can be divided into single-channel conditioner, double-channel conditioner and three-channel conditioner;

- According to its structure, it can be divided into ordinary conditioner, spacer conditioner and differential diameter conditioner. device.

For the processing of sunken fish feed, double-layer and triple-layer conditioners are required.

Two layers of conditioner are adequate, but three layers of conditioner are better. Customers can make the final decision according to their own raw materials, formulations, product needs and budget.

- Due to the long contact time between the steam and the material, the double-channel conditioner and the three-channel conditioner have more sufficient hydrothermal treatment, and their conditioning and aging effects are obviously better than those of the single-channel conditioner.

- Spacer conditioner has better conditioning effect than common conditioner due to less energy loss. Due to the full contact and mixing of steam and materials, the differential conditioner has a good conditioning effect.

Therefore, in the production of aquatic feed, it is best to choose fish feed pelleting machine with a three-channel conditioner or a differential diameter conditioner, or at least a double-channel conditioner or a spacer conditioner.

fish feed pelleting machine Ring die selection

At present, in many countries, the majority of aquafeeds are still hard pellets. Therefore, the performance of the fish feed pellet machine has a great influence on the quality of the granules.

Quantity plays a very important role. There are many types of fish feed granulators on the market, and their performances are quite different.

- In particular, the selection of the pressure roller and die parameters of the feed pellet machine should pay attention to the thickness and compression ratio of the die. Compared with the die used for livestock and poultry pellet feed, the die used to make aquatic pellet feed must be thicker and have a higher compression rate.

- The hardness of pellets formed by different ring dies increases significantly with the increase of compression ratio. Choosing a suitable compression ratio ring die can produce pellets with suitable hardness.

- The length of the pellets has a significant impact on the pressure-bearing capacity of the pellets. For pellets with the same diameter, if the pellets have no defects, the longer the pellet length, the greater the measured hardness. Adjust the position of the cutter to maintain a suitable pellet length, so that the hardness of the pellet can be kept basically the same.

- Pellet diameter and section shape also have a certain influence on pellet hardness. Figure 8-shaped cross-section has stronger pressure bearing capacity than circular cross-section, and the measured hardness value is also larger.

- In addition, the material of the fish feed pelleting machine ring die also has a certain influence on the appearance quality and hardness of the pellets. The pellets produced by ordinary steel ring die and stainless steel ring die are significantly different. (Maybe you are interested in:5t/h aqua feed plant)

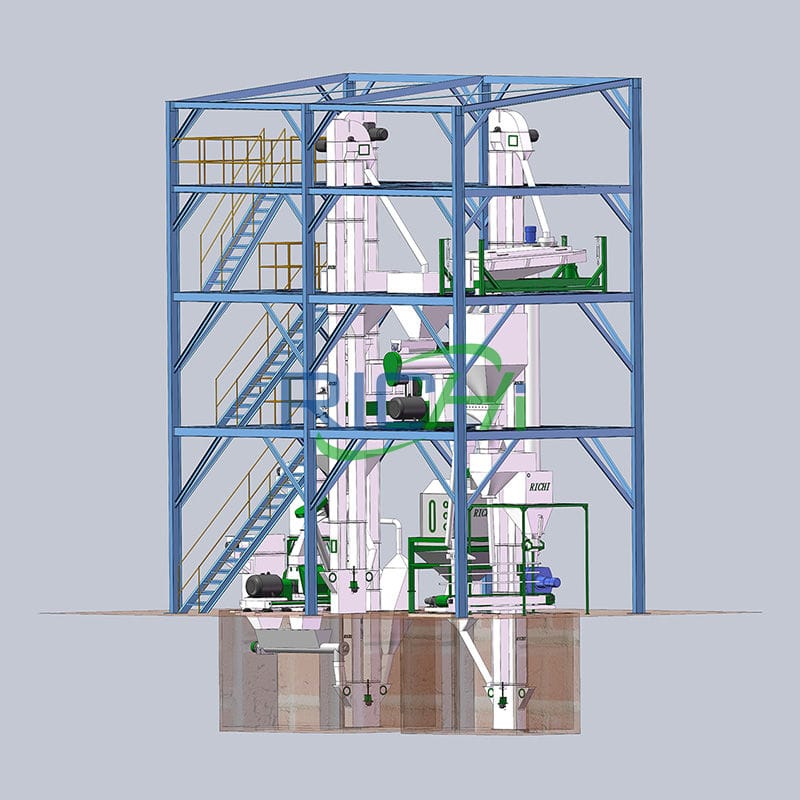

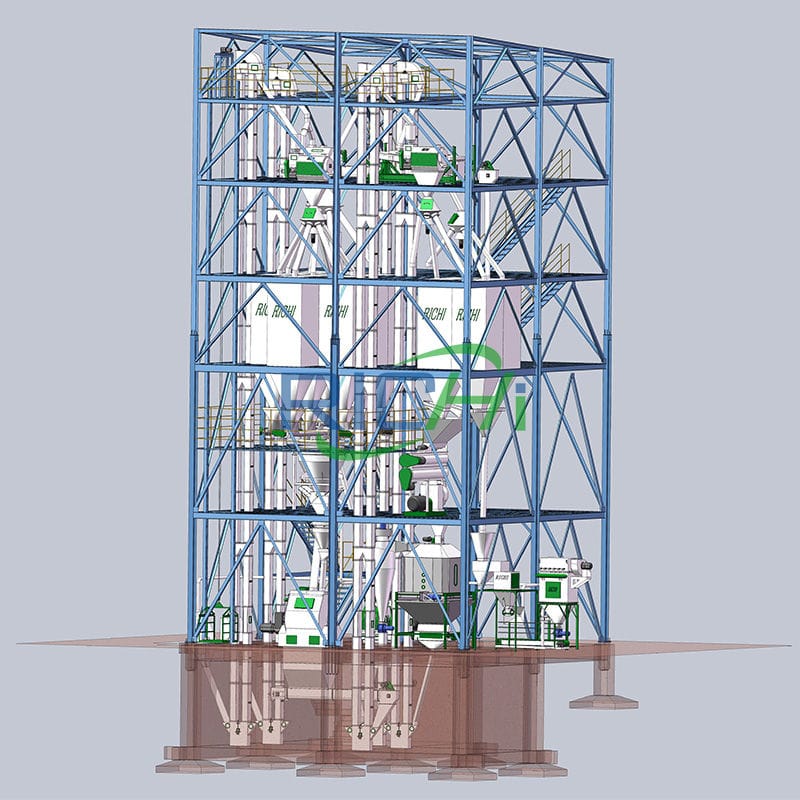

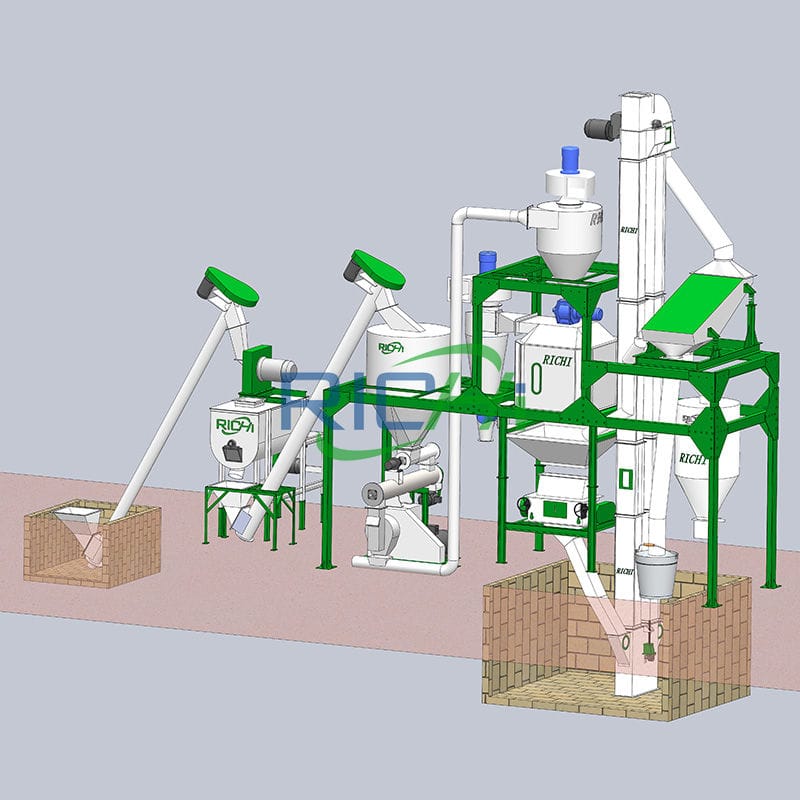

Complete sinking fish feed pelleting technology

Generally speaking, if you want to start a large-scale fish feed processing, you need to build a fish feed production line, which requires many workshops and equipment to form a feed processing system.

The process plan of making materials into pellets and the selection of excellent machinery and equipment are directly related to the quality of water feed. Nowadays, most of them use ring die pellet machines to pellet feed, and use fish feed hammer mill, fish feed mixers, pellet coolers, screening machines, packing scales, etc. as auxiliary equipment.

The aquatic feed making process mainly includes feed raw material reception, raw material removal of impurities and iron, crushing or fine grinding, batching, mixing, transportation, cooling, screening, weighing and packaging, etc.

Complete sinking fish feed production process:

(1)Grinding section

The raw material crushing process is one of the main processes in the aqua feed production line. The crushing particle size of the raw material determines the surface area of the feed composition.

Within a certain range, the finer the particle size of the raw material, the better the stability of the processed feed pellets. In the fish feed pellet production process, the appropriate crushing particle size should be selected according to the requirements of the fish feed pelleting machine.

Generally, the crushing particle size of raw materials for common aquatic feed (such as carp, grass carp, silver carp, etc.) is 40-60 mesh, and the crushing particle size of raw materials for special aquatic feed (such as prawns, eels, soft-shelled turtles, etc.) should reach more than 80 mesh.

Moreover, the post-crushing process can be used in the production of most freshwater fish feeds, and sometimes the pre-crushing and post-crushing processes can be used comprehensively, especially for materials that require micro-grinding. The advantages of using this process are more obvious.

(2) Batching device

Batching refers to the process of accurately weighing a variety of different feed materials by using a specific batching device according to the requirements of the feed formula. Batching equipment generally includes various batching scales, batching bins, manual feeding ports, mixers and subsequent conveying equipment, and its core is batching scales (including feeders).

A reasonable batching device can enhance the batching accuracy, improve feed quality, improve feed water stability, and help shorten the batching cycle and enhance production management.

The key to the process composition of the batching device is the correct selection of the batching device and its coordination with the batching bin and mixer.

At present, common process devices have multiple warehouses and one scale, multiple warehouses with two scales, multiple warehouses with three scales, one warehouse with one scale, and multiple warehouses with several scales, etc. Manual platform scale batching and continuous quality batching processes can also be applied. (Maybe you are interested in :5 t/h aqua feed plant)

(3) Mixing device

Mixing is the mixing of various materials under the action of external force, so that the proportion of each component in each small volume in the stockpile is consistent, and it is an important production link to ensure the quality of aquatic feed.

Most of the aquatic feed processing adopts the secondary mixing process, and for the selection of the secondary mixing mixer, generally the horizontal ribbon mixer is used for the first mixing, and the double-shaft mixer with a coefficient of variation of mixing uniformity CV≤5% is used for the second mixing. Paddle efficient mixer.

The selected mixer should mix the materials evenly in a short period of time, so as to ensure that the mixing time does not exceed the crushing time, and it can be equal or similar to the batching cycle of the batching scale to enhance the stability of feed water.

(4) Conditioning

Conditioning is a process of improving physical and chemical properties through heat and humidity treatment. This process helps to increase feed cohesion and plasticity, ensure fine structure of feed, improve hardness and stability of aquatic feed in water. After the powder feed is conditioned, the water content increases and the temperature rises, which is convenient for pelleting by fish feed pelleting machine.

Controlling the temperature, time, pressure and moisture of conditioning is crucial to the quality of feed conditioning. The increase of tempering temperature can enhance the water resistance of the feed under certain conditions.

In production, the appropriate temperature should be selected according to the characteristics of raw materials and the stability of feed water. Usually, the tempering temperature of aquatic feed should be controlled at 80-95 °C is preferred.

Within a certain range, the longer the tempering time, the better the gelatinization degree of the starch in the raw material, the higher the cohesiveness, and the better the quality of the feed. Feed factories can use the method of first pelleting and then curing and tempering to enhance the quality of aquatic feed water. stability.

During granulation, the steam pressure has a great influence on the stability of the pellet feed water, but from the comprehensive consideration of boiler safety production and energy consumption reduction, the steam pressure should be 0.35-0.40Mpa. As for the influencing factors of tempering moisture, the moisture content of general raw materials should be controlled at 16% to 19% when they are put into the mold.

(5) Pelleting

Granulation is the process of forming powdery compound feed or single raw material into granular feed through extrusion. Granulation technology has a great influence on the water resistance of products but it is easy to be ignored.

Under the premise of certain raw materials, formula and process, the smaller the length-to-diameter ratio of the ring die, the shorter the feed stable time, and vice versa, the longer it will be.

At present, the most commonly used feed pellet machine in fish feed mills is the ring die fish feed pelleting machine. The fish feed factory should reasonably select the ring die, adjust the distance between the die and the position of the cutter according to the requirements of different aquatic feeds, the characteristics of the raw materials and the processing technology.

Conditional aquatic feed mills can also repeat the pelleting process to improve the water stability of the feed. The quality of the granulation effect is closely related to its granulation time, strength, temperature and other factors.

The fish feed pelleting machine with double conditioner has a better granulation effect, which can prolong the passage time of the material in the conditioner, improve the maturity and increase the stability.

Controlling the granulation intensity can make some feed granules compact in structure, reduce the contact area between feed granules and water, effectively prevent the infiltration of external water, make it water-resistant for a long time, and improve stability. During granulation, the feed temperature has a great influence on the water resistance of the granules.

Under certain conditions, the higher the feed temperature, the better the water resistance.

- If the temperature is too high, the humidity of the material will be too high, resulting in blockage of the die hole;

- if the feed temperature is too low, the water resistance will be poor, and the power will also be increased consumption, reducing economic benefits.

(6) Cooling after pelleting

Cooling uses flowing natural air to reduce pellet feed temperature and simultaneously reduce moisture. After cooling, the fish feed pellets change from the damp, hot and soft state just after fish feed pelleting machine granulation to a pellet feed with proper hardness, suitable water content and normal temperature.

During production, the appropriate cooling air volume and cooling time should be selected according to the characteristics of the material and the type of cooler, so as not to affect the hardness and wear resistance of the pellets and reduce the stability.

The hardness of the cooled feed increases, which can effectively prevent the entry of external water and enhance the stability of the pellet feed in water.

Usually, the temperature of the sunken fish feed just discharged from the fish pellet cooler is 6-9℃ higher than the room temperature, and the water content after cooling is 12%-12.5%.

(7) Screening

After cooling, the pellets are sieved to remove the powder, and the powder is sent to the fish feed pelleting machine, but the powder ratio should not exceed 5%, because the processing process is irreversible, and the increase in the proportion of recycled feed will reduce the stability of the pellets in water.

For the screening of sinking fish pellet feed, the grading sieve preferably has two layers of appropriate screens. Feed processing technology has complex and changeable factors affecting feed quality.

In order to improve quality and increase output, it is necessary to fully consider various factors in the production process, constantly analyze and adjust the process and parameters, and constantly renovate the equipment.

(8) Packaging

The finished products after screening will enter the packaging section for sale. Customers can choose different packaging parameters according to their needs.

Richi Machinery has nearly 30 years of production experience. Our products are exported to many countries and regions at home and abroad, and are the common choice of tens of millions of users.

The sinking fish food production line launched can be customized according to customer requirements, flexible configuration, and can be matched with different pulverizers, mixers, fish feed pelleting machines, coolers, screening machines, spraying machines, etc. If you have more questions about the sinking fish feed production plant, Please consult customer service online, and we will answer you one by one.

Related solutions

About Richi Machinery

Richi Machinery was founded in 1995 and since then has produced pelletizing units and wear parts for the entire pelletizing technology sector.

The company’s core business includes supplying market-oriented interior design of aquafeed plants, complete production of partial systems (crushing, mixing, pelletizing, drying, cooling, baling), customer-focused sales and well-organized services. Since then, RICHI SZLH series sinking fish feed pelleting machines have been used successfully all over the world.

Since the establishment of Richi Machinery, the company has become a competent partner for all pellet production industries and has developed into one of the leading manufacturers in the field of pellet mills.

BV certification

CE certification

ISO certification

SGS certification

- Richi Machinery has produced sinking fish feed equipment for many years. It has several mining machine research institutes. It is more proficient in the production technology of aquatic fish feed pelleting machines and aquatic feed extruder equipment. The production equipment will pass the inspection of third-party equipment departments to ensure sales. The quality of equipment in the hands of users.

- The ring die type fish feed pelleting machine produced by Richi Machinery is more affordable. This manufacturer belongs to the direct sales type, and all equipment directly faces users, saving the price difference between middlemen, lower costs, and strong quotation discounts.

- Richi Machinery’s services are relatively complete. The service system of pre-sales, sales and after-sales is combined and interlocking. Every user who has been to RICHI can feel the warmth of a friend.

We adhere to the principle of “pre-sales, sales and after-sales”, formulate plans for customers before sales and deliver them in person, install them for customers during sales, return visits from time to time after sales, and understand the operation of the fish feed pellet production line.

If necessary, please feel free to consult us, or come to visit the factory.

After-sales follow-up visit service

- Technical engineering personnel participated in the whole process of visits, after-sales service engineers and front-line salesmen stationed abroad fully cooperated.

They went deep into the feed production line from a more professional technical perspective, felt the mood of customers during the use of equipment, understood the operation of equipment, and collected equipment problem during production, provide customers with on-site technical guidance.

And at the same time grasp product trends during the visit, provide effective market demand materials for later research and development, and do a good job in products and services.

- Products are the core of customer needs, while service is the value-added and extension of customer satisfaction. Owning Richi Machinery equipment also means having the care of a complete after-sales service system. The competition in the future is the competition between brands. Brand means quality, method, management and service.

Therefore, Richi Machinery determined the strategy of “extending to the product industry chain” and “treating customers as friends”, focusing on the research and development of feed equipment, focusing on the value creation of customers, and focusing on higher-level business models, so as to realize the relationship with customers. win-win situation between.

Richi Machinery is a professional manufacturer of aquatic feed equipment. The series of sinking fish feed pelleting machines produced have high reliability and practicability, and the price of fish feed pellet machines is reasonable. Since the product was sold, it has been deeply loved by customers. Welcome customers to visit RICHI Factory and learn more about our products.

Related products

6-7T/H Fish Pellet Machine

7-10T/H Fish Food Pellet Making Machine

12-15T/H Fish Food Pellet Machine

15-18T/H Pellet Machine For Fish Feed

18-20T/H Fish Feed Pellet Making Machine