This is a large-scale aquatic shrimp crab fish food factory project (including the processing of aquatic feed such as fish, shrimp and crab extruded feed, submerged pellet fish feed, shrimp and crab mixed feed).

The project is divided into two phases:

- The first phase is 2 high-end aquatic extruded feed production lines (16-17t/h freshwater fish extruded feed production line and 8-9t/h shrimp and crab extruded feed production line), specially for high-end fish, shrimp, high-end crab feed and other special aquatic products.

- The second phase is 2 aquatic pellet feed lines (12.5t/h sunken fish feed pellet production line and 4-5t/h shrimp and crab pellet feed production line), aiming at the high density shrimp farming mode, while radiating high-level pond farming.

The total production capacity is expected to reach 100,000 tons.

Why build a new aqua feed factory?

Why did the client of this shrimp crab fish food factory project choose to invest in this large-scale aquatic feed mill factory when many clients were operating light assets?

- Because this client company has been engaged in high-end aquatic feed processing business before, and has high requirements on feed technology, it is difficult to transform the original small aquatic feed factory. After inspecting several factories, it decided to build a new factory.

- In addition, it is the feedback from farmers that gives customers the greatest confidence. Because based on good formula and technology, the products of this client company have been able to bring better profits to farmers.

Good formula + good equipment + good market environment, why not start a large-scale aquatic feed processing business to gain more profits?

To develop the feed processing sector, the customer started with four varieties of white shrimp, catfish, crab, and sunken fish. On the one hand, the market demand promotes the development of varieties, and on the other hand, it is the advantage of the customer company.

The fish and shrimp fed with the products of the client company are of high quality, which makes the client very confident in developing these feed varieties.

- Construction nature: newly built;

- Occupied area: 38721 m²;

- Total investment: 20 million US dollars (including all civil construction).

- Employees: 168 people, of which 50 are accommodation personnel.

- Working system: One shift system is adopted, each shift is 8 hours, and the annual working day is 300 days.

Product plan

The main products of this 40-42t/h shrimp crab fish food factory project are fish, shrimp, crab extruded feed and pellet feed, with a total output of 100,000 tons per year. The specific product plan is shown in the table below.

| Product Name | Capacity (t/a) |

|---|---|

| Freshwater fish extruded feed | 40000 |

| Submerged Pellet Fish Feed | 30000 |

| Shrimp and crab pellet feed | 20000 |

| Shrimp and crab extruded feed | 10000 |

Construction Content

This 40-42t/h shrimp crab fish food factory project mainly builds new factory buildings, raw material warehouses, finished product warehouses and supporting rooms, and purchases and installs a complete set of feed production equipment. The project design and construction content and scale are as follows:

- Production workshop: Covering an area of 27m*43m, the main equipment includes elevators, batching systems, pulverizers, spraying machines, shrimp feed pellet machine, crab feed pellet machine, fish feed dryer, shrimp feed dryer, etc. Two sets of extruded feed production lines and two pellet type aqua feed production lines are built. The annual production of fish 100,000 tons of shrimp and crab feed;

- Raw material warehouse: covers an area of about 5400m², mainly used for storage of soybean meal, peanut meal, rapeseed meal and other raw materials;

- Finished product warehouse: covers an area of about 5400m², used for storage of various aquatic feed products;

- Transportation: Belt conveyors and forklifts are mainly used in the factory, and the transportation outside the factory depends on external transportation vehicles;

- Office building: The construction area is about 1350m², which is used for the daily office work of employees;

- Dormitory: 2 buildings, with a construction area of about 3510 m², used for staff accommodation;

- Machine repair room: covers an area of about 14m*16m, responsible for daily maintenance of equipment;

- Accessory room: covers an area of about 14m*16m;

- Boiler room: covers an area of about 18m*18m, equipped with a 10t/h natural gas boiler.

Main Raw and Auxiliary Materials

The raw and auxiliary materials and energy used in the 40-42t/h shrimp crab fish food factory project are detailed in the table below:

| Name | Annual consumption (t/a) |

|---|---|

| Fishmeal | 4700 |

| Soybean meal | 28500 |

| Peanut Meal | 10000 |

| Rapeseed meal | 22500 |

| Flour | 6500 |

| Shrimp bran | 1700 |

| Soybean oil | 2700 |

| Corn | 14600 |

| Phospholipids | 950 |

| Vitamins Minerals | 3000 |

Energy consumption

| Name | Annual consumption (t/a) |

|---|---|

| Electricity | 11.1 million kwh/a |

| Water | 35070m³/a |

| Gas | 2.022 million Nm³/a |

Equipment for 40-42 t/h shrimp crab fish food factory

In this aqua feed mill project, Richi Machinery provided system design, installation, and commissioning services for the entire aquatic compound feed production line, including feeding, batching, crushing, mixing, granulating, cooling, and finished product packaging.

In addition, 36 large double-layer batching bins are provided, with a single bin capacity of 180 cubic meters, 12 premix bins, 14 bucket elevators and other supporting equipment.

The main aqua feed equipment list is as follows:

| Device Name | Model Specification | QTY |

|---|---|---|

| Scraper Conveyor | TGSSp25 | 9 |

| Bucket Elevator | T400 | 12 |

| Bucket Elevator | TDTG50/28 | 14 |

| Cylinder Primary Cleaning Screen | TCQY100 | 2 |

| Cone Powder Sieve | SCQZ90×80×110A | 1 |

| Fish Feed Grinder | SWFP66×125 | 2 |

| Twin Shaft Paddle Mixer | SLHSJ4 | 5 |

| Superfine Pulverizer | SWFL150 | 10 |

| Aquatic Feed Pellet Machine | SZLH678 | 2 |

| Extruded Feed Dryer | / | 2 |

| Cooler | SKLN24*24A | 2 |

| Crumbler | SSLG15X150 | 2 |

| Automatic Packaging System | 40KG | 2 |

| Aquatic Feed Extruder | RCPH185*2 | 2 |

| Shrimp And Crab Feed Extruder | RCPH150*2 | 1 |

| Sprayer | PTZL2000 | 2 |

| Aquatic Feed Dryer | SDZB3000-11 | 2 |

| Rotary Classifier | SFJZ150×200 | 4 |

| Rotary Classifier | SFJH130×3C | 2 |

| Rotary Classifier | SFJH140×2C | 2 |

| Automatic Packaging System | 25KG | 2 |

| Gas Boiler | 10 T/H | 1 |

| Pulse Dust Collector | / | 29 |

Large Aqua feed production Process design

In this 40-42 t/h shrimp crab fish food factory project, Richi Machinery provided a series of high-end aquatic feed equipment and complete engineering solutions. Combined with the customer’s production situation, it configured the customer with the batching first and then the crushing process, the raw material double-layer bulk warehouse storage system, and the real-time feeding of the silo.

The material status is displayed, the finished products are released in bulk, and all the processing machines provided are selected from the standardized and complete RICHI product series to realize automated, safe and efficient production. The current total production capacity of the aqua feed factory is 40 tons/hour, and the reserved capacity is 20 tons/hour.

(1) Aqua feed extrusion process flow

It is used to process extruded feed for freshwater fish and extruded feed for shrimp and crab.

- ① Feeding: Raw materials such as soybean meal, corn meal and rapeseed meal are unpacked, poured into the feeding port, and sent to the screening section through scraper conveyor and bucket elevator.

- ② Screening: The raw materials are pre-cleaned to remove impurities such as stones and iron filings, and then sent to the coarse crushing section by elevators.

- ③Coarse crushing: The raw materials that need to be crushed, such as soybean meal that has been screened and removed, are sent to the crushing bin, and then the crushing machine is used for preliminary crushing.

- ④Ingredient mixing: According to the product formula requirements, the crushed soybean meal and other raw materials are measured and sent to the mixer, and then the flour, fish meal and other raw materials that do not need to be crushed are added to the mixer through the adding system, and various raw materials are stirred and mixed in the mixer. uniform.

The feed mixer used in this 40-42 t/h shrimp crab fish food factory project has a short mixing cycle; it adopts sprocket and chain transmission, and it runs smoothly; with a double-shaft structure, the material is discharged quickly and the residue is small. - ⑤Ultrafine pulverization: Use the conveyor to send the powder into the ultrafine pulverizer for further pulverization, reaching an ultrafine particle size below 100 mesh.

- ⑥Secondary mixing and tempering: The processed ultrafine raw materials, small materials, water, oil, etc. are added to the mixing mixer according to the formula requirements for secondary mixing and conditioning, so that the product components meet the quality requirements.

- ⑦Extrusion: The feed is heated by high-temperature steam in the aqua feed extruder, and in an environment of high temperature, high pressure, high shear force, and high moisture, through continuous mixing, tempering, heating, pressurization, aging, extrusion die hole and sudden pressure reduction Finally, it is the process of forming a kind of bulky and porous feed.

After the feed is expanded, the fragrance will increase, and nutrients such as protein, fat, and starch will be more conducive to digestion and absorption, and the quality of the product will be improved. The steam required for heating the fish feed extruder is provided by a 10t/h gas boiler in the 40-42 t/h shrimp crab fish food factory project - ⑧Drying: The moisture content of the extruded feed is relatively high, so it is necessary to use a dryer to volatilize the excess moisture to obtain a product with a moisture content that meets the quality standard. The heating heat of the feed dryer is provided by a natural gas boiler.

- ⑨Grease spraying: Due to the high temperature of the puffing process, it is easy to lose the grease in the feed. It is necessary to use a fuel sprayer to spray grease on the surface to ensure the full price of the feed and improve the palatability and quality of the product.

- ⑩Cooling and packaging: use the flap cooler to cool the feed temperature from about 50℃ to room temperature. The product warehouse is temporarily stored for sale.

(2) Aqua pellet feed processing flow

Production process of submerged pellet feed and shrimp and crab mixed feed

- ①Feeding section: the same process as the extruded feed, and the equipment is shared.

- ②Screening: Same process as extruded feed, shared equipment.

- ③Coarse crushing: the same process as extruded feed and shared equipment.

- ④Batching mixing: same process as extruded feed, equipment sharing.

- ⑤Superfine crushing: the same process as extruded feed and shared equipment.

- ⑥Secondary mixing and tempering: the same process as the extruded feed, and the equipment is shared.

- ⑦Pelleting: The mixed raw materials enter the aqua shrimp crab fish pellet mill, are heated by steam to 80℃ for gelatinization, and extruded to make pellet feed with a certain density and strength.

The gear box transmission efficiency of the shrimp prawn feed pellet machine used in this section is 99%, which is higher than that of other peers; it adopts European standard design and has strong stability; double-layer insulation door.

The steam required for heating the aqua feed pellet machine is provided by a 15t/h gas boiler in the 40-42 t/h shrimp crab fish food factory project. The feed pellets produced in this section have a smooth surface, flat fracture, uniform length, uniform pellets, and water resistance of more than 10 hours. - ⑧Drying: It is necessary to use a feed dryer to volatilize the excess water to obtain a product with a moisture content that meets the quality standard. The heat heated by the aqua feed dryer is provided by a natural gas boiler.

- ⑨Cooling and crumbling: Use a cooler to cool the feed to room temperature. Since various animals have different requirements for the size of the pellet feed, after crushing with a crusher, pass through a grading sieve to obtain finished feed that meets the specifications. The rotary grading screen used in this section is equipped with a screen surface cleaning device, which has high screening efficiency, low energy consumption and easy maintenance.

- ⑩Packaging: Use an automatic packaging machine to pack products into bags, and store them in the product warehouse temporarily for sale.

It is worth mentioning that the current aquaculture environment puts higher requirements on all aspects of shrimp farming, especially the new environmental protection policy, which highlights the contradiction of heating in some areas.

In response to this situation, the pelleted shrimp feed produced by this 40-42 t/h shrimp crab fish food factory project has been upgraded in formula to enhance the food-attracting effect of the feed in a low-temperature environment.

During the cold winter period, it also ensures the feeding and growth rate of shrimp, and guarantees the time to market. It is said that the customer’s new product has already been tested in aquaculture farms in many countries, and the feedback has been good.

According to different farming models, the requirements for the quality of the purchased shrimp will also be different. For example, in industrial shrimp farming, shrimp trucks have high requirements for body color, followed by the survival rate of long-distance transportation.

The customer seized the two major pain points of factory-produced shrimp to develop and upgrade shrimp feed, and truly solved the problem of shrimp quality. As a result, the client company has a high presence in many regional markets.

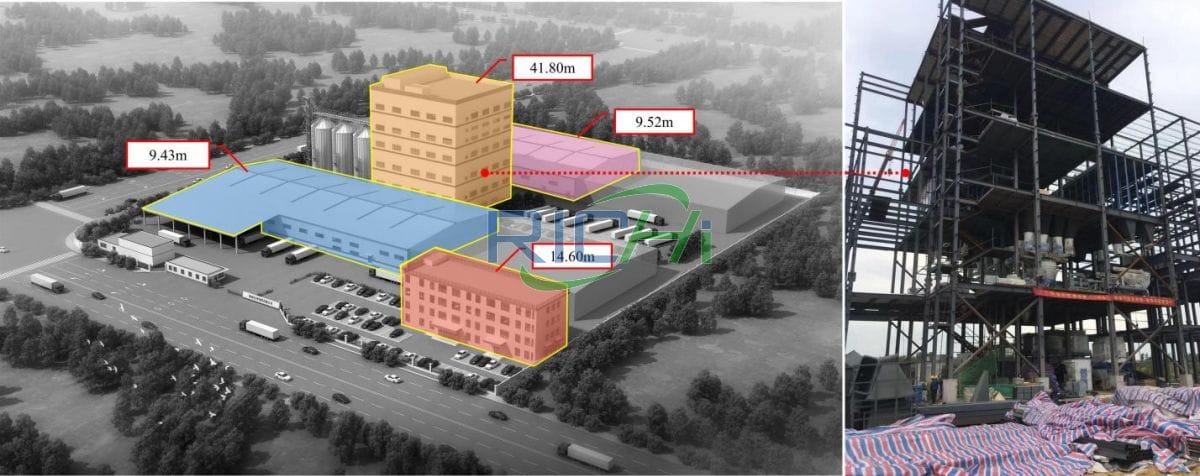

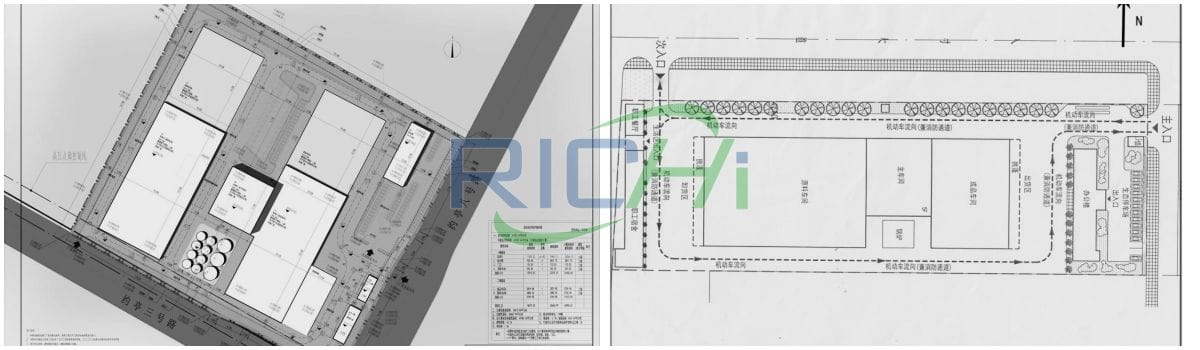

40-42 t/h shrimp crab fish food factory layout

The area where the shrimp crab fish feed factory project is located has convenient traffic conditions, and the park has complete power supply, water supply, gas supply and drainage facilities. The land used for the project is in the nature of industrial land, which meets the requirements of local land use planning. The project will build a new production plant, 2 warehouses, 1 office building, 2 dormitories and other ancillary facilities.

The production plant is located in the middle of the plant area, the west side of the plant is the raw material warehouse, and the east side is the finished product warehouse. The office building is located on the northeast side of the factory area, and the dormitory is located on the southeast side.

The boiler room, machine repair room and accessories room are located on the north side of the factory. The functional division of the project is reasonable and easy to manage.

Civil engineering

①Basic engineering

It mainly refers to paving, leveling and compacting the entire plant area of the aquatic feed factory, and the time for this stage is relatively short. Due to some problems in the transportation roads adjacent to the factory, the client company also funded the road improvement at its own expense.

②Main building

The production workshop of the shrimp crab fish feed production plant project mainly adopts all-steel structure, and the two warehouses, office buildings and staff dormitories adopt mixed-steel structure. The civil contractor of this project is a well-known local enterprise of the client. The duration of this section is longer.

③Decoration works

This stage is to paint the factory buildings, office buildings, dormitories, warehouses, etc., and paint the exposed components. In addition, the office building and dormitory are also renovated, and supporting office and accommodation facilities are purchased. This session is shorter.

④Equipment installation

Including the installation of a full set of aquatic feed production line equipment and other environmental protection equipment, boilers and other auxiliary equipment, the installation period is 2 months.

Public works

① water supply and drainage

The main water used in the 40-42 t/h shrimp crab fish food factory project is domestic water and production water for employees. The water is connected from the main municipal tap water supply pipe, and the annual water consumption is 35070 m³/a.

The drainage of the aqua prawn crab fish feed plant project adopts the rain and sewage diversion system, and the rainwater enters the rainwater pipe network; the domestic sewage (including canteen wastewater) is pretreated in the oil-separating septic tank. The boiler room wastewater is directly discharged, and the wastewater is discharged into the sewage pipe network of the park, and the wastewater is brought into the sewage treatment plant.

②Power supply

The electricity used by the project comes from the municipal power supply pipeline network, which can meet the needs of the project operation period, and the annual electricity consumption is about 11.1 million kwh/a.

③ heating

The drying of the project uses the heat generated by natural gas combustion, and the annual consumption of natural gas is about 2.022 million m³ /a. The natural gas comes from the natural gas pipeline in the park, which can meet the production demand.

④ Firefighting

In this project area, indoor and outdoor fire hydrants are installed in accordance with the requirements of the “Code for Fire Protection Design of Buildings” to meet the fire protection needs.

The entire project went through hundreds of processes from project approval to engineering commissioning and acceptance.

Richi Machinery arranged technical product experts, engineering management teams, business managers and after-sales service members to provide full-process services to provide high-standard guarantees for customers’ high-end aquatic feed processing projects.

If you also want to establish your own shrimp crab fish food factory and carry out aquatic feed processing business, please contact us to customize the plan and consult the process of building a factory!