Floating Fish Pellet Machine For Sale

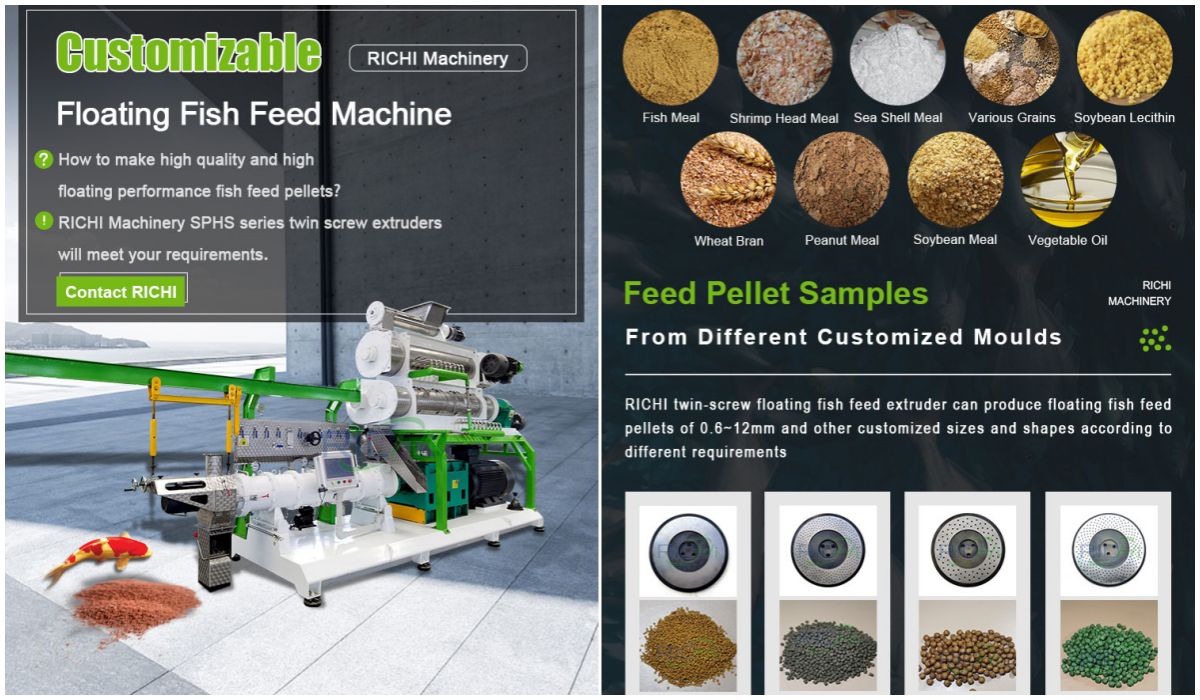

RICHI specializes in floating fish pellet machine for sale, our floating fish feed pellet machine is used to produce floating feed, slow sinking feed and sinking feed and other ideal feed forms suitable for the development of modern aquaculture industry. It has great development space and has good market prospects in various countries around the world.

On the basis of introducing advanced technologies on floating fish feed machines and upgrading the screw fish feed extruder design, Richi Machinery develops and researches a new generation of fish feed extrusion equipment. Our floating fish feed pellet machine has multiple independent property rights, and now, of which, twin screw floating pellet machines and wet fish feed extruders have become the core equipment in fish feed production industry.

(Here RICHI will mainly show you the details of the 10-12 t/h extruder pellet machine)

- Capacity: 10-12T/H

- floating feed machine price: 190,000-220,000 USD

Types of floating fish pellet machine for sale

Extrusion is formed by the comprehensive action of moisture, heat, mechanical energy, pressure, etc., and is a high-yield, short-term processing process. According to the level of moisture in the raw materials, it can be divided into dry extrusion and wet extrusion. Our 10-12t/h fish floating feed machine adopts wet extrusion, and we also supply a wide range of fish feed pellet extruders.

Customers who know aquafeed processing know that twin-screw fish floating feed machines are definitely the future of the aquafeed industry.

If they pursue feed quality and longer-term economic benefits, aquafeed manufacturers usually only buy twin-screw fish feed pelleting machines. However, for small-scale aquatic feed processing, single-screw wet type extruder fish pellets machines are also common equipment.

RICHI is mainly engaged in floating fish pellet machine for sale, all the Types of floating fish feed pellet machines available from RICHI include:

01

From the screw structure

Single-screw extrusion and twin-screw extrusion

02

From the processing technology

Wet extrusion and dry extrusion

Dry type floating fish pellet machine for sale

Dry extrusion processes products using friction alone as a heat source. The material is heated up, and under the action of the extrusion screw, the material is forced to pass through the die hole, and a certain pressure is obtained at the same time.

After the material is extruded from the die hole, the pressure drops sharply, the water evaporates, and the volume of the porous structure formed inside the material increases, thereby achieving puffing. For the purpose of dry expansion, the moisture content of dry expansion is generally 15%-20%.

- Capacity: 0.03-2 T/H

- Price of dry type small floating fish feed machine: 2800-30000 USD

Wet type floating fish pellet machine for sale

Wet extrusion is to add steam for pre-conditioning, and the final product needs to be dried. However, the moisture content of wet-expanded materials is often higher than 20%, or even more than 30%. In addition, the heating part of the material is achieved by adding steam.

In the extrusion process of wet floating fish pelleting machine, starch can be gelatinized, and the palatability of feed can be improved, the loss of nutrients can be reduced, the utilization rate of feed products can be improved, and the water resistance time of aquatic feed can be prolonged.

- Capacity: 0.18-4 T/H

- Price of wet type floating fish feed pellet mill: 4500-40000 USD

Single screw floating fish pellet machine for sale

Single-screw floating fish food pellet machines have been widely used, and have the advantages of small investment and low processing cost. It can be pre-conditioned or not according to needs. Therefore, it can be used for both wet and dry purposes.

At present, more than 80 countries are using single-screw fish feed extruders, which are mainly used for the extrusion of soybeans and other oilseeds, and a few are used for the production of aquatic feed, pet feed, food, etc. However, the scope of application is limited, especially the high-fat and high-moisture materials cannot be processed.

- Capacity: 0.03-4 T/H

- Price of single screw floating feed machine price: 2800-40000 USD

Twin-screw floating fish pellet machine for sale

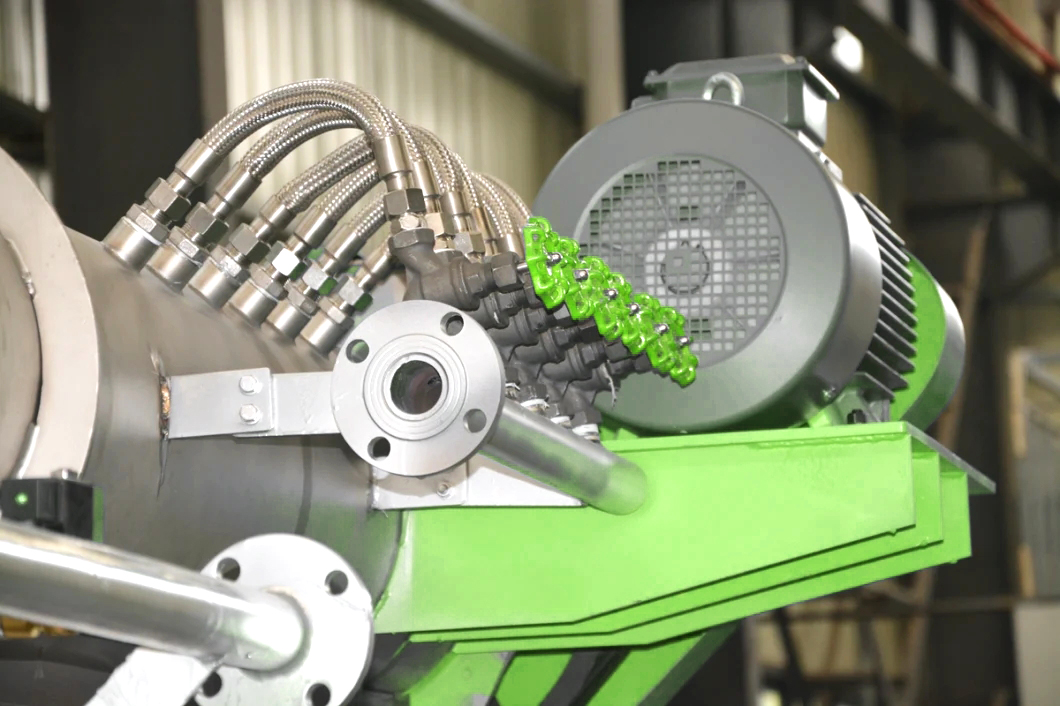

The twin-screw floating fish feed pellet making machine relies on a pair of screws that mesh with each other in parallel to push the material forward. During the extrusion process, the material conveys stably, does not slip, and is not easy to block the machine.

It is more suitable for extrusion processing of materials with high moisture and high oil content. Aquatic feeds, especially marine fish feeds, generally have higher fat content, so twin-screw fish extruder pellet machines are more suitable.

- Capacity: 1.5-12 T/H

- Twin-screw floating fish feed machine price: 70,000-200,000USD USD

In recent years, with the introduction, digestion and absorption of advanced fish feed extrusion machine technology by Richi Machinery, the production technology level of twin-screw extruder fishing pellet making machine has been continuously improved.

The investment of the single screw fish feed making machine can also choose the twin-screw model, thus changing the concept that people used to hinder the use of the twin-screw model due to the high investment cost.

As a manufacturer specializing in floating fish pellet machine for sale, from fish feed extruder machine model selection and solution design at the early stage, production capacity enhancement and product mix optimization at the intermediate stage, to after-sales services at the later stage, we have fish food extruder machine and floating fish food production line project managers there helping you avoid risks and add project value.

Advantages of Twin Screws floating fish pellet machine

For a long time, Richi Machinery has focused on the R&D and manufacturing of floating fish pellet machine and the floating fish pellet machine for sale, our twin-screw floating fish feed pellet machine has the following advantages:

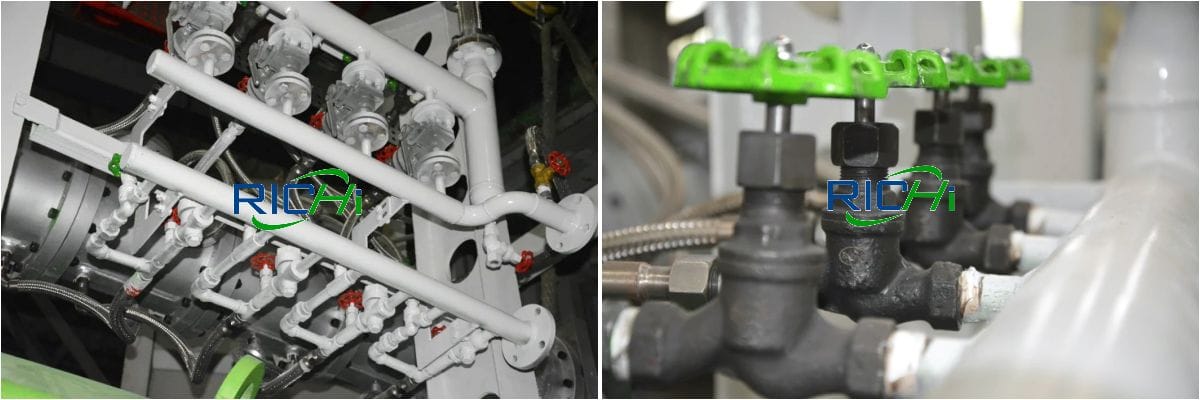

- The characteristics of twin-screw fish feed extruder forced conveying and self-cleaning make the material stay in the barrel for a short and uniform time.

- The good mixing performance of the twin-screw fish floating feed machine makes the heat obtained by the material uniform in time, accelerates the degree of maturation of the material, reduces the fluctuation of the material temperature, and improves the output and quality of the extruded product.

- Precise and unique double-screw structure increase soil content up to 22%.

- Increase the absorption rates of oil for animals.

- Advanced hole layout technology and die hole structure make pellets uniform and smooth.

- Use PLC Touch Screen Technology to realize man-machine dialogue and switch between manual and automatic operation.

- Long service life, mould and gear > 5000h.

- It can process fast sinking feed (such as shrimp feed) with about 30% starch.

- Produce 100% floating feed and 100% sinking feed only with a kind of screw.

- Reduce the dependence of feed formula and save the cost of raw materials. The output of sinking feed can be increased by 10%-20%.

In order to meet the needs of the development of the feed industry and improve product quality, Richi Machinery has been attaching importance to and promoting the application of twin-screw extrusion technology in feed processing, giving full play to the wider adaptability of raw materials and products of the twin-screw floating fish pellet machine.

Better internal and external quality of products, higher output under the same power, better curing and homogenization effect, easier process operation, lighter wear of wearing parts, and lower production costs, which make fish feed processing lines in new construction.

When expanding the production line of special feed such as aquatic feed and pet food, there are more reasons to choose the twin-screw fish feed extruder machine. (Maybe you are interested in building a shrimp feed plant)

Parameters of Floating Fish Pellet Machine (Twin screw type)

Only the model parameters of the twin-screw fish feed extruder equipment are listed here. If you want to know about other models, please contact Richi Machinery directly online.

10-12T/H Floating Fish Pellet Machine For Sale

- Anti-caking bin: PGS900/800 (2.2+0.3KW)

- Inverter feeder: WLQ219-1300 (2.2KW)

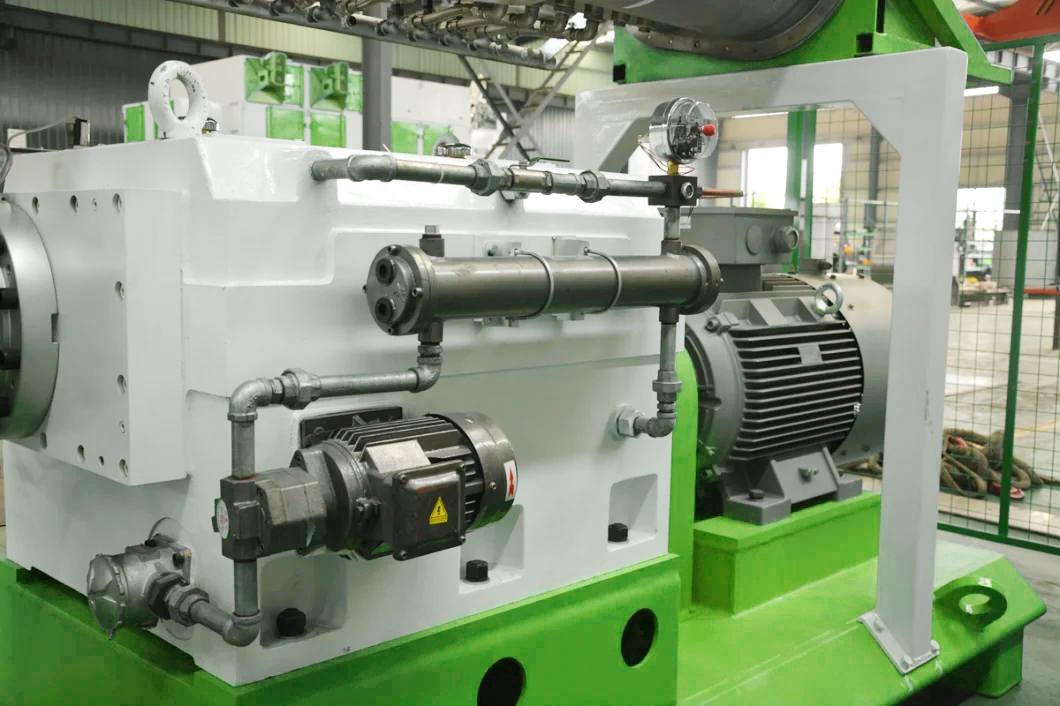

- DDC-conditioner: DC600/300 (15KW)

- Twin screw extruder: RCPH185*2 (355KW)

- PLC Controlling System

different models of floating fish pellet machine for sale:

1.5-2T/H extruder machine for fish feed

- Anti-caking bin: PGC900/700 (1.5KW)

- Inverter feeder: WLQ219×1200 (1.5KW)

- DDC-conditioner: DC400300-244 (11KW)

- Twin screw extruder: RCPH1202 (75KW)

- PLC Controlling System

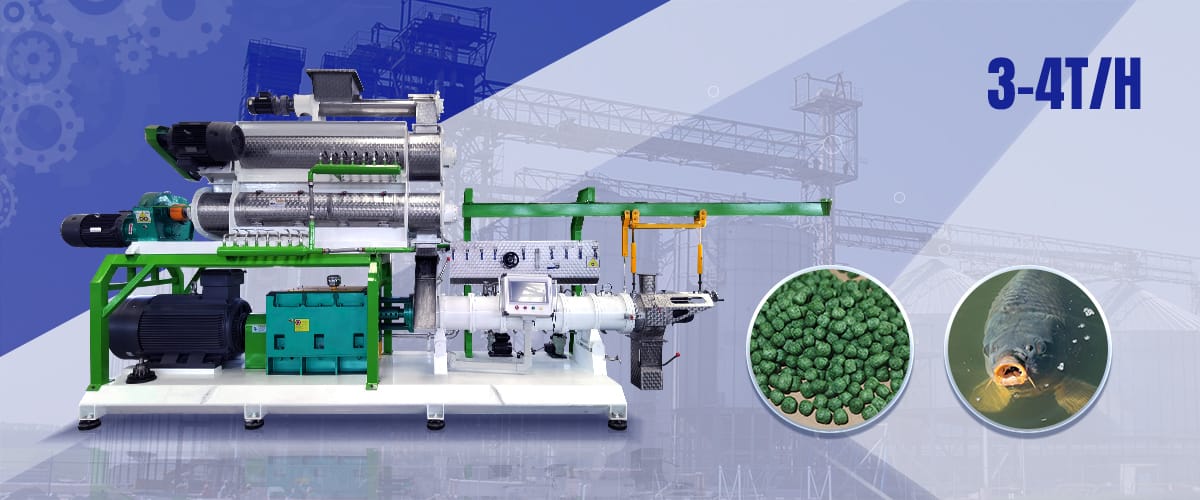

3-4T/H floating fish feed extruder machine

- Anti-caking bin: PGC900/750 (1.5KW)

- Inverter feeder: WLQ219×1200 (1.5KW)

- DDC-conditioner: DC400300-244 (11KW)

- Twin screw extruder: RCPH1202 (90KW)

- PLC Controlling System

4-5T/H floating fish feed pellet making machine

- Anti-caking bin: PGS900/800 (1.5+0.3KW)

- Inverter feeder: WLQ219-1300 (1.5KW)

- DDC-conditioner: DC500/244 (11KW)

- Twin screw extruder: RCPH150*2 (160KW)

- PLC Controlling System

6-7T/H floating fish feed pellet mill

- Anti-caking bin: PGS900/800 (1.5+0.3KW)

- Inverter feederp: WLQ219-1300 (1.5KW)

- DDC-conditioner: DC500/244 (11KW)

- Twin screw extruder: RCPH150*2 (200KW)

- PLC Controlling System

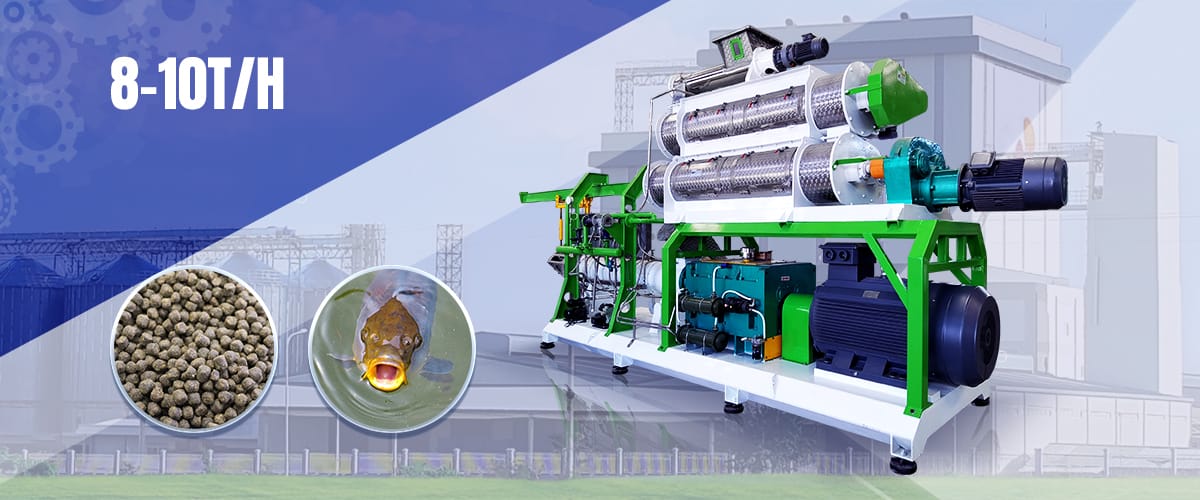

8-10T/H Fish Feed Pellet Extruder

- Anti-caking bin: PGS900/800 (2.2+0.3KW)

- Inverter feeder: WLQ219-1300 (2.2KW)

- DDC-conditioner: DC600/300 (15KW)

- Twin screw extruder: RCPH185*2 (315KW)

- PLC Controlling System

As a manufacturer focusing on the floating fish pellet machine for sale, Richi Machinery can offer such core feed extruder machines like twin screw floating fish pellet machine, single screw floating pellet machine, wet fish pellets machine and dry pelleting machine for fish. So far, we have developed 7 series which include over 60 machine models that can be matched freely so as to meet various demands on yielding and types of extruded feed fish.

Price of floating fish pellet machine

—— RICHI MACHINERY ——

10-12T/H floating feed machine price: 190,000-200,000USD, 1-12t/h floating fish pellet machine price: 70,000-200,000USD. The investment cost of the twin-screw floating pellet machine is 1.5-1.7 times that of the single-screw floating pellet machine with the same production capacity; the electricity consumption and cost of wearing parts are about 1.5 times that of the single-screw extruder.

So far, 70% of aquafeed production in the United States and 100% of aquafeed in South Korea have used extrusion technology. In many countries, more and more feed processing enterprises are gradually replacing traditional fish feed pellet mills with extruders to produce aquatic feed and other special feeds.

In the current aquafeed market, due to financial constraints, most aquafeed manufacturers usually choose single-screw fish feed pellet extruder machines with lower prices. It is used to produce low-grade floating feed for freshwater fish in processing, and it is difficult to produce sinking feed and other high-grade aquatic feed products.

Although some imported single-screw models can meet the production of high-grade sinking feed products, their prices are too high, and they have no good cost performance.

When choosing floating fish pellet machine, customers should not only see that the price of twin-screw fish feed extruders is higher than that of single-screw pellet machine for fish feed, but should also consider comprehensive cost-effectiveness and product production costs.

The technical performance of the high-quality twin-screw fish feed production machine has reached a certain advanced level.

Although the price is higher than that of the single-screw fish food extruder machine, it is far lower than the price of some brands of single-screw models, and its production performance has exceeded the imported single-screw model can completely replace the brand twin-screw model, which can not only meet the needs of medium and high-grade aquafeed in the aquaculture industry, but also achieve a high cost performance. It should be the best choice for the current aquafeed processing industry.

Extrusion technology is widely used in food, aquatic feed and pet feed, and now it is also widely used in the processing of poultry feed and pig feed. Improving nutrient digestibility and energy utilization improves feed efficiency and often improves animal performance. Indeed, the use of twin-screw fish feed pellet extruder machines increases production costs.

However, if you are a fish feed manufacturer, you must know: To be competitive in aquaculture and animal production, fish pellet feed extruder machines, especially twin-screw floating fish pellet machines, must be considered effective.

floating fish pellet machine for sale the world

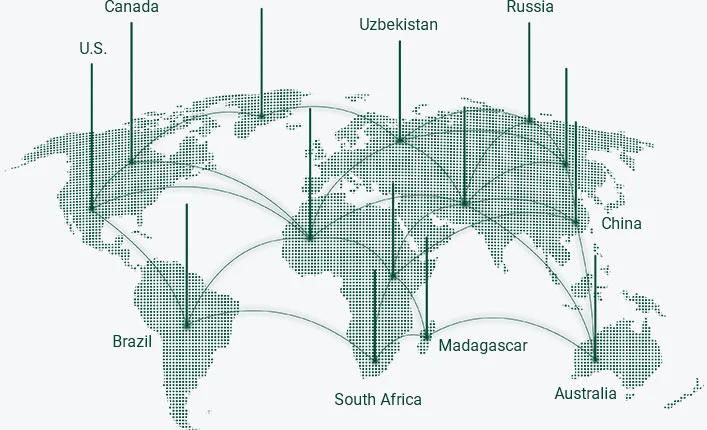

RICHI has many successful fish feed extruder projects in floating fish feed production, sinking fish extruded feed production and Ornamental fish feed processing fields, including:

- 5-6T/H floating fish pellet machine for sale Russia

- 10-12T/H fish pellet machine for sale Russia

- 1.5 -2T/H fish food machine for sale Iran

- 5T/H sinking & floaitng fish feed mill in Russia

- 1T/H wet extrusion feed production line in Honduras

- 1T/H floating fish feed line in Senegal

- 1T/H fish pellet machine for sale Nigeria

- 1T/H floating fish pellet machine for sale Congo

- ..

With the rapid development of aquaculture and people’s increasing attention to environmental protection issues, the production of aquafeed by extrusion processing technology is widely used. The fish feed extruder machine has become the preferred processing equipment for new or renovated aquatic feed plants.

How to choose fish feed extruder machine?

When building a new floating fish food production line, the type of floating fish pellet machine should first be considered when selecting a floating pellet machine.

It is necessary to choose the twin floating fish pellet machine that matches the force; especially when the old aquatic feed mill is renovated, it should also consider whether the production capacity of the original pulverizer, dryer and cooler is sufficient.

In addition to the price of fish pellet extruder machine, several issues should also be considered when choosing. As a manufacturer specializing in floating fish pellet machine for sale, Richi Machinery will give you some tips below:

01 The puffing effect of the floating fish feed pellet machine

For aquatic feed, the good puffing effect is that the particle forming rate is more than 99%, the particle pulverization rate is less than 1%, the particle floating rate (sinking rate) is 100%, the particle size is uniform, the color is consistent, and it has good water resistance. ; Floating type aquafeed is kept in water for 10h, sinking type aquafeed is kept in water for 3h without collapsing, etc.

02 The service life of floating fish pellet machine

Extrusion machines from different manufacturers have different service lives due to different structural characteristics and materials used.

Therefore, when selecting a floating fish feed pellet machine, special attention should be paid to the wear resistance of some wearing parts, and whether its structural design is reasonable and whether it can achieve the purpose of reducing screw wear.

In addition, when selecting a floating fish pellet machine, it is necessary to consider whether the machine can really achieve the purpose of saving energy and reducing consumption.

For the raw materials that have not passed through the ultrafine powder, the wear of the wearing parts will be more serious, especially the twin-screw fish extruder machine. In this case, it is more reasonable to use the single-screw floating fish feed machine.

In order to ensure the production of good aquafeed by extrusion technology, it is necessary to have a good understanding of extrusion technology and process, including fish feed puffing machine manufacturers, nutritionists, quality inspectors, operators and raw material purchasers.

Knowing and collaborating, only their joint efforts can truly produce a good extruded aquafeed.

03 Control method of floating pellet machine

Most extrusion processes are manual or semi-automatic operations. The quality of the extruded products has a lot to do with the quality of the operators themselves.

The artificial control of the feed, the rate of addition of steam and water, and the temperature of the product will result in unstable product quality.

Especially the non-uniformity of moisture, so that the moisture content after drying does not reach the target, producing substandard products, which brings great economic losses to the fish food factory.

Taking the aquatic fish feed extruder with an hourly output of 6 tons per hour as an example, when the pellet moisture exceeds the safe storage moisture, the pellets will become moldy; when the pellet moisture reaches the safe storage moisture, the annual economic loss of the aqua feed production line will reach 10% for every 1% reduction in water.

The fully automatic control method adopts advanced computer to control the flow of materials, water and steam, automatically adds according to the settings, and implements an alarm for all faults, eliminating the influence of human factors related to the operation of the fish aqua feed extruder machine and the unavoidable fluctuation of product quality.

At present, due to the limitations of the original production process conditions and equipment, the aquatic feed manufacturers in many countries only account for a small part of the extruded aquatic feed, and the single-screw fish pellet feed extruder machine is the main one, mainly due to the twin-screw floating fish feed pellet mill. The floating feed machine price is high, and the technical performance and quality of the twin-screw feed extruder of some manufacturers are still far behind. But as a manufacturer deeply involved in floating fish pellet machine for sale, the RICHI twin-screw fish extruder machine can completely break your stereotype of existing fish feed extrusion technology.

10-12T/H floating fish pellet machine working principle

Extrusion is a curing process under high temperature, high pressure, high shear, and most of them are also high moisture conditions. RICHI pellet machine for fish feed integrates many functions, such as crushing, shearing, mixing, and heat treatment, so it can be regarded as a reactor.

After extrusion, it can gelatinize starch, denature protein, kill microorganisms and destroy harmful and toxic factors. At the same time, the density of the material can be changed and the shape of the product can be controlled as needed.

With the strengthening of the breeding system, including the increase of breeding density and the increase of nutrient input, people’s requirements for environmental sanitation and green feed are more urgent.

From a processing technology standpoint, fish feed production machines are more effective at improving feed digestibility than other forms of processing. Using easily digestible raw materials, high digestibility can be achieved by extrusion.

The higher the digestibility of raw materials, the less pollution to the environment. Therefore, fish food extruder machine technology will play a greater role in the production of aquafeed in the future.

Richi Machinery specializes in floating fish pellet machine for sale. As for every floating fish feed pellet making machine and fish feed extrusion line project, Richi Machinery is willing to make every effort to customize suitable scheme for our customers and to help them get profits quickly with our professional knowledge. If you have no idea of fish aqua feed extruder machine price and aqua feed plant investments, please contact us directly.

Comparison of single and twin screw floating fish pellet machines

Generally speaking, single-screw floating fish pellet machines for fish feed production are often used for the pretreatment of a single variety of raw materials and some general and feed processing that do not require high processing quality.

It has poor adaptability to material changes and product requirements changes. Fish feed extruder equipment used in larger-scale aquafeed production typically have a screw with a length-to-diameter ratio greater than 10:1. The larger the aspect ratio, the wider the adjustable range of the adaptability of the fish extruder.

Compared with single-screw fish feed extruders, twin-screw floating fish feed machines can be used in a wider range.

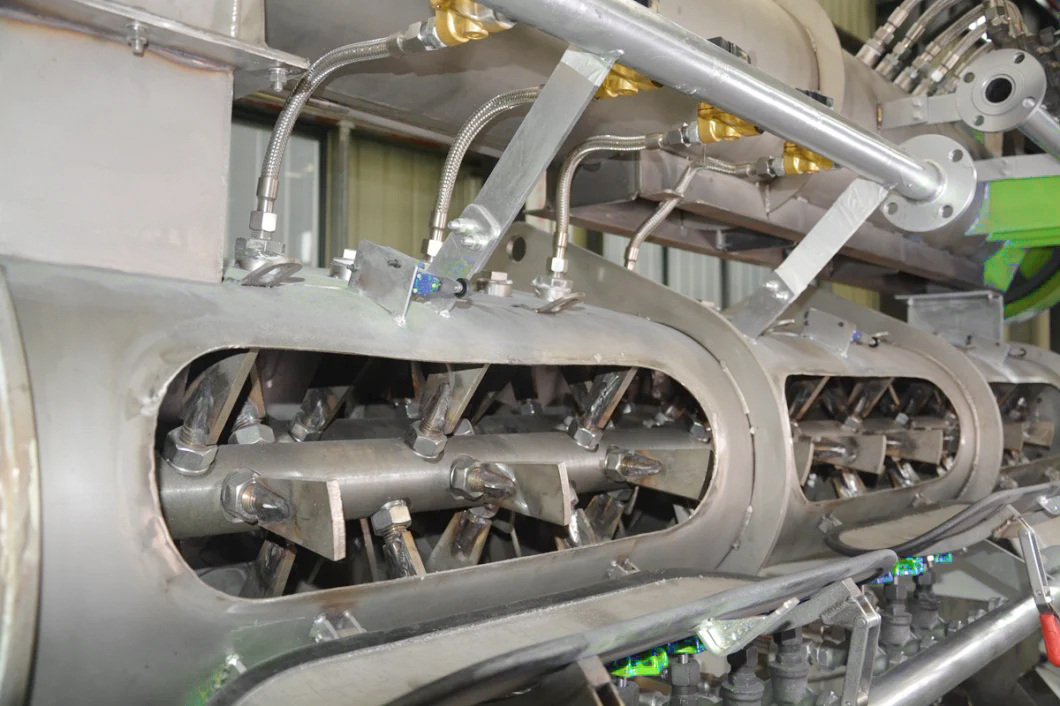

Due to the assistance of the two screws, the direction of the material during the extrusion process is ideally controlled, avoiding the reverse gap flow that occurs in the single-screw floating fish feed pellet machine, so that the material is balanced in force, the residence time in the machine is consistent, and the product is uniform.

Even if the moisture content of the raw material is greater than 40% and the oil content is greater than 17%, a product with a high molding rate can still be obtained.

The twin-screw fish feed extruder machine does not need to set resistance grooves on the inner wall of the machine bore, and when the two screws are working, they clean up the materials adhering to the screws.

Supporting equipment for fish feed extruder machine

Auxiliary facilities are indispensable in fish feed production lines, so Richi Machinery attaches great importance to the development of these facilities including conveyors, screening machines, sprayer, and cooling machine. Until now, RICHI has pushed out more than 30 series auxiliary facilities successively.

Delivery of extruded feed

The feed that has just come out of the extruder machine is hot, watery, very fluffy, and emits a lot of steam. There must be suitable means of transportation to reduce product damage and environmental impact. The more appropriate conveying forms are negative pressure pneumatic conveying and belt conveying. The former is more common, rather than ordinary elevator conveying. In addition, escaping steam must be sucked off or the machine head must be perforated to prevent steam from condensing on the feed and the machine.

Drying of extruded feed

The feed made by floating fish feed extruder machine needs to be dried slowly. If the temperature is too high or the flow is too fast, the internal moisture of the feed product cannot evaporate from the center of the pellet. This will allow the moisture to escape over the next few days, eventually causing the feed to go mouldy. Therefore, the drying time, speed and temperature must be coordinated and controlled well, and the drying process must maintain a certain depth of material layer and proper turning. Therefore, the better drying equipment is a horizontal belt circulating fish feed dryer machine.

Post-spraying and cooling of extruded feed

The dried product can be post-sprayed with grease. This advantage is that the hot product can quickly absorb the oil, so that the water resistance of the pellets is enhanced, the fish feed will be more suitable for the taste of the fish after spraying the oil, and the appearance value of the product is greatly improved.

However, it must be cooled by pellet cooler machine after the grease is sprayed, and the temperature of the cooled material should not be higher than the ambient air temperature by 4°C, so as to ensure the safe storage of the packaged feed. Otherwise, if the hot feed is packaged directly, the heat cannot be dissipated in time, which will accelerate the oxidation of fat, and also cause the surface moisture to condense and mildew.

Richi Machinery has a full coverage of fish feed extruder machines, fish feed pulverizers, fish feed mixers, dryers, fish feed coolers, fish feed screening machine and fish feed packaging machines. We make each aqua feed mill machine with great care to forge excellent quality.

Application of floating fish pellet machine

Aquatic feed can be divided into four categories: floating feed, semi-floating feed, sinking feed and slow sinking feed. The main advantage of using the extrusion method to produce aquafeed is that both sinking and floating feeds can be grown with the same equipment.

The difference is how to control the temperature, pressure, etc. during processing, which is also a difficulty in the processing process. However, as long as the characteristics of the fish aqua feed extruder are mastered, the ideal extruded feed product can be processed.

So, how to use the aquatic fish pellet feed extruder machine to produce floating extruded feed, semi-floating extruded feed and sinking feed?

01 Produce floating extruded pellet feed

The temperature of the feed after conditioning by the feed mixer, that is, the temperature before the feed enters the extruding cavity. In actual production, the temperature of the feed after being tempered and tempered by the feed mixer is generally controlled at 80-90℃.

After entering the extruding chamber, the material gradually moves forward and the temperature rises slowly. When it reaches the template at the front of the extruding chamber, the temperature can reach 130- 150℃, the pressure is about 3MPa.

When the feed is extruded from the template, the pressure drops sharply, and the temperature drops slowly, the liquid phase water in the feed is suddenly vaporized, which promotes the expansion of the pellets, and the feed can float in the water without sinking.

The density of the product processed by this method is 0.3-0.4kg/L, and the water content is 21-24%.

02 Produce sinking extruded pellet feed

In the production of sinking feed, the operating conditions of the fish feed extruder machine should be adjusted to suit the production of feed with a density of up to 0.45-0.55kg/L. After the feed has been conditioned and tempered, the temperature has reached 80-90 ℃.

In order to make the feed heat up quickly, a group of strong shearing and kneading pressure screws are installed to strengthen the temperature rise, so that the mechanical energy can be quickly converted into heat energy.

Hot steam is introduced into the sleeve, and the result of this joint action will make the feed heat up rapidly, and the starch will gelatinize rapidly, so that the material becomes a plastic body. In order to make the final produced product a sinking feed, it is necessary to reduce the temperature, moisture content and expansion of the product.

03 Produce semi-moist feed and slow sinking feed

The production technology of semi-moist feed with fish feed extruder machine is similar to that of floating feed, the only difference is that liquid is added in the mixer to increase the water content in the feed to 30-32%. The production of slow-sinking feed with an aquafish feed pellet extruder is similar to the production of sinking feed.

However, during the processing process, the density of the final product must be controlled. The density of this product is usually 0.39-0.41kg/L, which is exactly the feed. The density at which it begins to sink in seawater. Therefore, a density determination must be carried out for each feed pellet.

RICHI fish feed extruder is independently designed by Richi Machinery on the basis of years of experience in fish feed making machine production. RICHI fish food extruder machine adopts the latest feed manufacturing technology and extrusion technology. The feed extruder machine integrating conditioning, puffing and transporting has become a better choice in the extruded feed fish industry.

Operation requirements of floating fish pellet machine

With the rapid development of the aquaculture industry and people’s increasing attention to environmental protection issues, the use of fish feed extruder machine technology to produce aquafeed is widely used. The following issues should be paid attention to when selecting extrusion equipment and designing extrusion process. (Find RICHI on Facebook)

When selecting fish feed extruding machine and designing extrusion processes, the first thing to consider is the product requirements, including:

Shape and size requirements;

Density requirements;

Nutritional requirements;

Water stability requirements;

Appearance requirements;

Other requirements of users.

The choice of feed formulation has a decisive impact on the quality, nutritional composition, morphology and economy of the finished product. The selection of raw materials should take into account not only nutritional requirements but also their processing properties.

For example, the crushing fineness of the raw material has an important influence on the appearance quality of the finished product, and also affects the stable production of the fish feed extruder machine. To produce high-grade aquatic feed, high-quality raw materials must be used, because extrusion processing cannot improve the quality of raw materials.

Protein

Protein is an important component of aquafeed, usually the content of the whole feed composition is 25% to 60%, or even higher. Protein raw materials are divided into two categories: vegetable protein and animal protein. The water absorption and cohesiveness of vegetable protein are better than animal protein, but its amino acid is not as good as animal protein, and its application has certain limitations. Therefore, both proteins should be used in the formula to avoid certain nutrient deficiencies.

Starch

Starch is usually the second most important component after protein in aquatic feed, and its content can be 5% to 60%. It is recommended that the starch content of sinking materials should not be higher than 10% to 15%, and the starch content of floating materials should not be less than 20%. In extrusion processing, carbohydrates also act as binders, suspending agents, and emulsifiers, which are important determinants of flavor properties.

Fat

Fats or lipids are a good source of energy for aquafeeds, and usually the total content in the formula does not exceed 22%, so that the energy consumption and wear of the wearing parts of the fish feed extruder machine are small. Lipid compounds in the formula will increase the palatability and energy content of the product, high content of lipid compounds will reduce the degree of bulking, and its lubricating effect can reduce energy consumption.

Fiber

Fibers, including cellulose, hemicellulose and lignin, are often used as fillers and also provide some nutrients. Adding a small amount of fiber to the product can improve the puffing effect, but if the content is too high, the puffing will be reduced instead.

Since the digestive tract of aquatic animals is short and thin, it is difficult to digest large and granular feeds, so it is necessary to reduce the fineness of raw materials. The aperture of the sieve plate of the hammer mill is usually only a minimum of 1mm, and it can only produce particles above Φ3mm. If you want to produce particles below Φ3mm, generally you need to use a micro pulverizer to meet the requirements.

The finer the fineness, the smoother the surface of the produced particles and the higher the maturation of the particles; in addition, the finer the fineness, the more stable the production of the fish feed extruder machine, and the smaller the wear of the wearing parts.

Starch not only provides energy for animals, but also is a necessary molding and shape retention material for feed products. Whether it is to produce sinking feed or floating feed, starch raw materials are indispensable, and starch can easily form a network structure after gelatinization, which reduces the density of the product, and the density of the product can be greatly adjusted by changing the starch content.

For the single-screw fish feed extruder machine with better performance at present, when producing floating feed, the starch content in the raw material should not be lower than 18%, and in the production of sinking feed, the starch content in the raw material should not be higher than 20%. For better quality twin-screw fish feed extruder machines, the above starch content can also be relaxed. Depending on the source of proteins, the difficulty of becoming a network structure varies greatly.

In addition, in terms of protein, low-temperature soybean meal can be used more in the production of floating feed, and more fish meal can be used in the production of sinking feed. Within a certain range, the increase of oil, minerals, and cellulose in the raw material will increase the density of the product.

The moisture of the raw material entering the machine refers to the moisture of the material when it enters the extrusion cavity. This parameter has an impact on output, power consumption, product quality, equipment service life and the working stability of the fish feed extruder machine.

As the moisture content of the material increases, the cost of steam and drying increases accordingly. The increase of moisture can promote the softening of the material and reduce the frictional resistance of the material to the equipment, thereby reducing the driving force requirement for the screw and reducing the wear of wearing parts.

In addition, the cost of raising the temperature of the material by steam is much lower than the cost of generating heat by friction through mechanical energy. Therefore, when the moisture content of the material is lower than 20%, increasing the moisture makes the operating cost of the system decrease in a straight line.

When the moisture content of the material reaches 25%, the increase of moisture has no obvious effect on the driving energy consumption and wear, and the system operating cost tends to be stable. The pulverization rate, water resistance, nutrient retention rate, adaptability to the change of raw material composition during processing, and fish feed extruder machine production capacity of feed products are reduced to quantitative indicators, which are called product characteristics.

Product characteristics are also closely related to material moisture. According to the change law of system operation cost and product characteristics, it can be concluded that the moisture content of the material is 22%~31% is the suitable operating parameter of the fish feed extruder machine.

The gelatinization degree is high, the water stability is much higher than that of ordinary pellet feed, the product density is adjustable, and it can process floating, slow-sinking, fast-sinking feed and high-moisture, high-fat feed, and the loose structure of the pellet is conducive to post-spraying. The floating fish pellet machine has unique advantages such as avoiding the loss of heat-sensitive raw materials, preventing environmental pollution, preventing and resisting diseases, improving the nutritional value of feed, and reducing production costs.

We specialize in the floating fish pellet machine for sale, with the emergence of large-scale, large-capacity and special-purpose RICHI twin-screw models, the use of RICHI twin-screw floating fish pellet machines can achieve greater benefits, and can give full play to the wide range of raw materials used in extrusion puffing processing technology. If you are interested in our floating fish pellet machine, feel free to contact us!

2,000+ /PROJECTS

In the past 30 years, as floating fish pellet machine manufacturer, we have accumulated rich experience. We has exported floating fish pellet machine for sale the world, and has reached cooperative relations with more than 2,000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

130+ /COUNTRIES

Customer experience is the touchstone. Richi Machinery has benefited a lot from winning the market with connotative products and high-quality services. Richi Machinery specialize in twin screw floating fish pellet machine for sale, our floating pellet machine is carefully designed for customers according to the actual requirements.