According to the physical characteristics of shrimp feed, the SZLH series shrimp feed pellet machine produced by RICHI is a kind of pelletizing equipment with low failure, easy operation, high efficiency and widened ring die. It is equipped with a main motor with a power of 75-132kW.

The shrimp feed pellet mill machine is the very core of the shrimp feed pelleting process. The shrimp feed pellet press compacts and forms the pellets. Before this, it is necessary to heat up and dampen the feed, which is done in the conditioner placed directly before the shrimp pellet machine.

We have lots of experience with supplying and installing pellet plants all over the world, and we can supply shrimp feed pellet making machines in different sizes. The single machine capacity varies from 0.1 to 6 tons/hour.

Physical characteristics of shrimp feed

Shrimp is a bottom-dwelling animal that lives in water. The individual is relatively small, and it feeds with its claws. It has a short digestive tract and poor absorption function. According to the physiological characteristics of shrimp, shrimp feed should have the following characteristics:

- The powder that makes up the feed should be ultrafinely pulverized so that the particle size is less than 80 mesh, so as to facilitate the digestion and absorption of shrimp;

- The particle size of the prepared particles should be less than 2 mm;

- The solubility of the feed relative to water is small, and it is required to keep it intact in the water for a certain period of time, so that the shrimps have enough time to ingest it;

- There is a protective film on the surface of the particles, which can effectively prevent the leakage of water-soluble nutrients. It can be seen that compared with livestock and poultry feed, shrimp feed has higher requirements.

For shrimp feed, you need to be able to formulate fast-sinking pellets, which retain their elastic structure even after hours in the water. Our technology gives you the precise control of the cooking and shaping you need to create a quality product with minimal waste .

Shrimp Feed Pellet Machine Features

The granulation process for producing hard granule aquatic feed is different from that of livestock and poultry feed. It requires the conditioning cylinder to feed evenly, the granulator to run smoothly, and the granule size to be consistent. The ring die compression ratio of fish feed is 1:11-1:14, while that of shrimp feed is 1:20-1:24; the ring die material of fish feed pellet machine is made of carbon steel or stainless steel, and the shrimp feed pellet processing machine needs to use stainless steel.

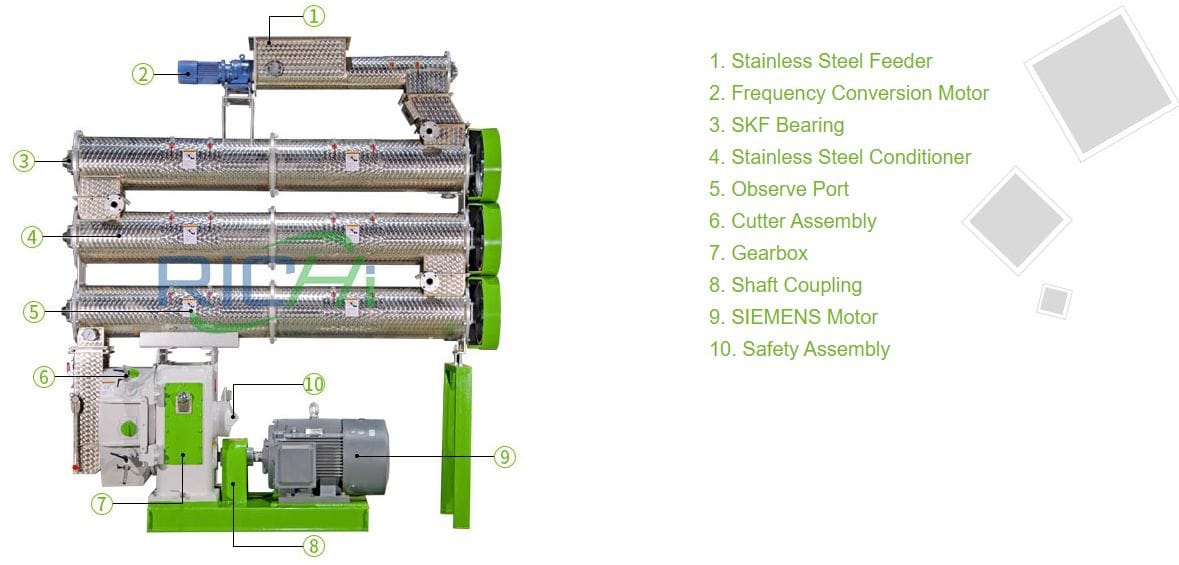

Shrimp feed pellets are required to be short and flat. The advent of RICHI’s unique gear transmission, three-layer conditioner, and two-roller shrimp feed pelletizing equipment enables the production of high-quality shrimp feed to be realized.

- The feeding adopts circular feeding cylinder and frequency conversion feeding, and the feeding cylinder is connected to the feeder to prevent arching and ensure uniform feeding;

- The conditioner uses a 3-layer jacket conditioner or a dual-shaft differential speed conditioner. The specially designed paddle installation form, the speed of the conditioning shaft and the steam addition system ensure that the material can be fully tempered and matured;

- The cutter mechanism is fixed on the box, and there is no need to withdraw the cutter when opening the door. The blade material is made of high-speed tool steel, or special alloy is welded on the tip of the blade. The thickness of the blade is 2-3 mm. The blade is close to the surface of the ring die, and the blade can realize fast replace(plug-in);

- Specially designed die hole structure and processing technology, the hole diameter is Φ1.5~2.5mm, the length-to-diameter ratio is 12:2~13:0, the mold hole finish is not more than 0.8, and the inner hole of the ring die is guaranteed to be discharged once. Grind out at the same time as the outer circle to ensure coaxiality;

- Design the special pressure roller and the surface form of the pressure roller;

- The main transmission adopts high-precision gear transmission, and imported bearings and oil seals are used to improve the reliability of the whole shrimp feed pellet machine;

- Improve the original feeding scraper, so that the material is evenly distributed to each pressing area and distributed uniformly within the effective length of each pressing area, so as to ensure uniform particle length after granulation;

- The linear speed of the ring die is designed according to the characteristics of the shrimp feed, which greatly improves the production capacity of the pellet mill and the appearance and internal quality of the pellets;

- The design of the chute conforms to the smooth flow of materials, and an air motor is added for external discharge;

- Automatic control system design and overload protection design of shrimp feed granulator;

- Equipped with pneumatic external discharging structure, realize automatic external discharging when it is blocked or overloading of the main motor current;

- The improved feeding scraper divides material into two pressing areas, ensuring smooth discharging and stable operation.

Shrimp Feed Pellet Machine Advantages

RICHI offers a complete line of durable, long-lasting, and versatile shrimp feed pellet mill to support your feed production needs. Our experts have the knowledge and experience to help you locate the right shrimp feed machine product for your application. RICHI provides the following Advantages for your feed production needs:

- Advice and guidance on your raw materials and formulations;

- Can provide all supporting equipment and customized system solutions for shrimp feed processing;

- Provide turnkey service;

- Excellent high volume discount pricing;

- Custom pellet machine production;

- ISO & CE certified.

Shrimp feed pellet machine parameters

| Model | Capacity(T/H) | Main Power(kw) | Feeder Power(kw) |

|---|---|---|---|

| SZLH250 | 0.1-0.2 | 22 | 0.75 |

| SZLH320 | 0.3-0.4 | 37 | 1.5 |

| SZLH350 | 0.5-0.7 | 55 | 1.5 |

| SZLH420 | 1.2-1.5 | 90 | 1.5 |

| SZLH508 | 2-2.2 | 132 | 2.2 |

| SZLH558 | 1.5-2.5 | 180/200 | 2.2 |

| SZLH678 | 3-4 | 220/250 | 2.2 |

| SZLH768 | 4-5 | 280/315 | 2.2 |

| SLZH858 | 5-6 | 280/315 | 2.2 |

Operating conditions of shrimp feed pellet machine

- Requirements Before Entering Pellet Mill: 95%≥80 mesh

- Pellet Diameter (mm): 1.2-2.0

- Pellet Length (mm): 1.8-4

- Ring Die Compression Ratio: 1:20—-1:25

- Conditoning Temperature (℃): 150

- Conditoning Time (s): 120-180

- Equipped Conditioner: three layers

Shrimp feed pellet machine price

Shrimp feed pellets machine price: 10,000-100,000 USD.

According to your actual needs, you can choose the position of the motor, stainless steel feed pelleting machine chamber door can be left-hinged or right hinged to suit the installation, the size of the feed screw, color, etc., and many more are available depending on the machine type. If the customized changes are large, it may cause price fluctuations.

Shrimp feed pellet machine cases

At present, our shrimp feed machines have been exported to Indonesia, Ecuador, India, Nigeria, Canada and other countries. For each project, RICHI will use professional knowledge and make unremitting efforts to create a suitable project plan for customers and help customers get a return on investment faster.

If you have no way to invest at the moment, you might as well consider a shrimp feed processing project with better prospects.

10T/H Large Shrimp Feed Processing Plant In China

1.5-2T/H Shrimp Fish Feed Pelleting Plant In Iran

Our services

- Professionally answer customer inquiries

- Recommend suitable products

- Tailor-made solutions

- Strict inspection and on-time delivery

- Assist in drawing up construction plans

- guide foundation foundation prefabrication

- Guide installation and commissioning

- Technical training and maintenance

- Regular testing and visits

Contact RICHI Machinery for Premium Shrimp Feed Pellet Mill Available in China

RICHI MACHINERY is your trusted supplier and distributor of premium aqua feed pellet machine, including shrimp feed pellets mill, fish feed pellet machine, and more. Contact us today to discuss shrimp feed pellet machine for your application.

FAQs of shrimp feed pellet production machine

Working principle of shrimp feed pellet mill

The ring die is rotated by the motor through the reducer, and the pressure roller installed in the ring die does not revolve, but rotates due to friction with the rotating ring die (by compacting the material).

The material that has been conditioned and tempered enters the pressing chamber, is evenly divided between the pressing rollers by the spreader, is clamped and squeezed by the pressing rollers, and is continuously extruded with high strength through the die hole of the ring die to form columnar pellets and the ring die ring rotates, and the pellet feed is cut into a certain length by the cutter fixedly installed outside the ring die.

The linear speed of the ring die and the pressure roller is the same at any point of contact, and the entire pressure is used for granulation. In the normal working process of the ring die, there is always friction between the ring die and the material.

What is the function of shrimp feed pellet machine conditioner?

- For the conditioner angle, almost every conditioner is installed horizontally. Add a loose leaf and a device that can raise the conditioner behind the conditioner, and use flexible feeding and discharge ports to realize almost arbitrary adjustment of the residence time.

- Under normal operating conditions, conditioning begins with the conditioner installed horizontally. Once stable operating conditions are obtained, the conditioner can be tilted to extend the residence time to the desired level.

- Long-time tempering generally adopts the method of increasing the tempering time to achieve the purpose of strengthening the tempering. With the continuous improvement of feed quality requirements and the rapid development of special aquaculture, conditioning methods such as multi-stage conditioning, aging conditioning after granulation, and high-pressure ring gap expansion conditioning have emerged.

- Multi-stage conditioning of shrimp feed pellet machine can improve the conditioning effect by prolonging the conditioning time, and the degree of starch gelatinization can reach 40% to 60%.

- Making and tempering after granulation is to keep the freshly pressed granules (about 80-85℃) warm, and let the hot granules last for a certain period of time in a high-temperature and high-humidity environment, so that the starch in the granulated feed is fully gelatinized, and the protein is fully transsexual. At the same time, the cracks generated in the early stage are pasted again to improve the durability of the feed to meet the special requirements of aquatic feed.

How to process high quality shrimp feed pellets?

In addition to requiring fresh raw materials, excellent prawn feed must also pay close attention to quality and particle size. Quality, not only hardness, pulverization rate and moisture content, but more importantly, water resistance; particle size mainly includes particle size and uniformity.

(1) Granularity control

For shrimp fry and juvenile shrimp feed, the pass rate of 60 mesh is required to reach more than 96%, while for medium shrimp and adult shrimp feed, the pass rate of 60 mesh is required to reach more than 90%. Therefore, the shrimp feed production line we designed usually adopts the superfine pulverization process.

(2) Control of water resistance, hardness and pulverization rate

The prawn feed contains a large amount of high-protein raw materials such as fish meal and soybean meal, and whole wheat flour containing α-starch. When shrimp feed pellet machine steam is added for heating and tempering, the protein denatures to increase the viscosity, and the starch is gelatinized to increase the viscosity. Steam, moisture, conditioning time will directly affect the water resistance, hardness and pulverization rate of the feed.

After the raw materials are crushed, they all pass through a grading sieve with a pore size of 0.18 mm. Three-stage conditioning is adopted. After conditioning, the moisture content of the material reaches 16.5%~18.0%, and the temperature of the material is 80~90°C.

During the stabilization process, the temperature is controlled at 90~100 ℃, the time is 1 h, and the water resistance of the final product is above 4 h, which can meet the water resistance requirements of shrimp feed. The apparent quality of hard pellet shrimp feed affects the water resistance and sinkability of the product. Cracks on the surface, uneven cuts, and inconsistent lengths will increase the loss rate of feed in water; inconsistent lengths and rough surfaces can reduce the sinking rate of products.

(3) Steam control

3% to 6% of the feed supply is introduced, the feed temperature is 85 to 95°C, the moisture is increased by 1% to 3%, the upper limit of moisture is 16.5%, and the steam pressure range is 280 to 350kPa.

(4) Moisture control

When the amount of water added to the mixer exceeds 3% to 4%, the hardness of the finished product increases sharply, which is due to the fact that the water promotes the starch α to some extent.

(5) Conditioning before granulation

Generally, the pre-conditioning time of shrimp feed pellet machine is about 3 minutes.

(6) Conditioning after granulation

Post-conditioning of prawn feed means that the granules are sprayed with molasses on the surface and then put into a conveyor similar to an “oven” to “simmer” for more than ten minutes. And the heat denaturation of protein, further make molasses penetrate into the granules, the purpose is to improve the hardness of the feed, the water resistance of the pulverization rate.

(7) Addition of molasses

Generally, the molasses used as compound feed is sugarcane waste molasses, and its sucrose degree is 79.5°. Due to the different adsorption of molasses by different raw materials and at different temperatures, no more than 3% should be added when mixing. In order to further improve the surface hardness and reduce the pulverization rate, it is necessary to spray 3% to 8% molasses after granulation.

Most economical shrimp feed pellet machine supplier

With the rapid development of the feed industry, high-quality, high-efficiency shrimp pellet feed machinery products have become an urgent requirement to support the development of aquatic feed. For this reason, starting from the performance of shrimp pellets, Richi Machinery optimized the parameters of the core components of the feed pellet machine—the ring die and the pressure roller.

The compression ratio of the ring die is precise, the service life of the ring die, pressure roller and other production accessories is extended, the production capacity and the cost performance of pelleting are improved, the appearance of the shrimp feed pellets is greatly improved, and the stability in water is better.

Taking the model SZLH420 shrimp feed pelletizer machine as an example, compared with the original power of 90KW, shrimp pellet diameter of 1.5mm, and productivity of 1.3 tons/hour, the productivity of shrimp pellets has increased by 15%. Finally, the cost per ton of pellet feed is reduced and the annual profit is increased.

Most of the aquatic feeds are hard pellets, and the performance of the pellet mill has a very important effect on the quality of the pellets. There are many types of granulators in the global market, and their performances vary widely.

Especially in the selection of the pressure roller and die parameters of the granulator, attention should be paid to the thickness and compression ratio of the die. Compared with the die used for pellet feed for livestock and poultry, the die used to make pellet feed for shrimp must be thicker and have a higher compression rate.

The design of the pelleting process and the selection of related shrimp feed machine are important factors affecting the quality of aquatic feed. At present, the equipment used for granulation includes shrimp feed pellet machines and shrimp feed pellet extruders, and related equipment includes granule coolers, granulators, grading screens, etc.

If you want to build your small, medium and large shrimp feed plant, please also contact us for customized shrimp feed production solutions.