The SZLH250 sinking fish feed pellet mill mainly produces hard pellet feed, which is suitable for benthic fish. In the granulation process of sinking fish feed processing, the pellet mill is the most important production equipment.

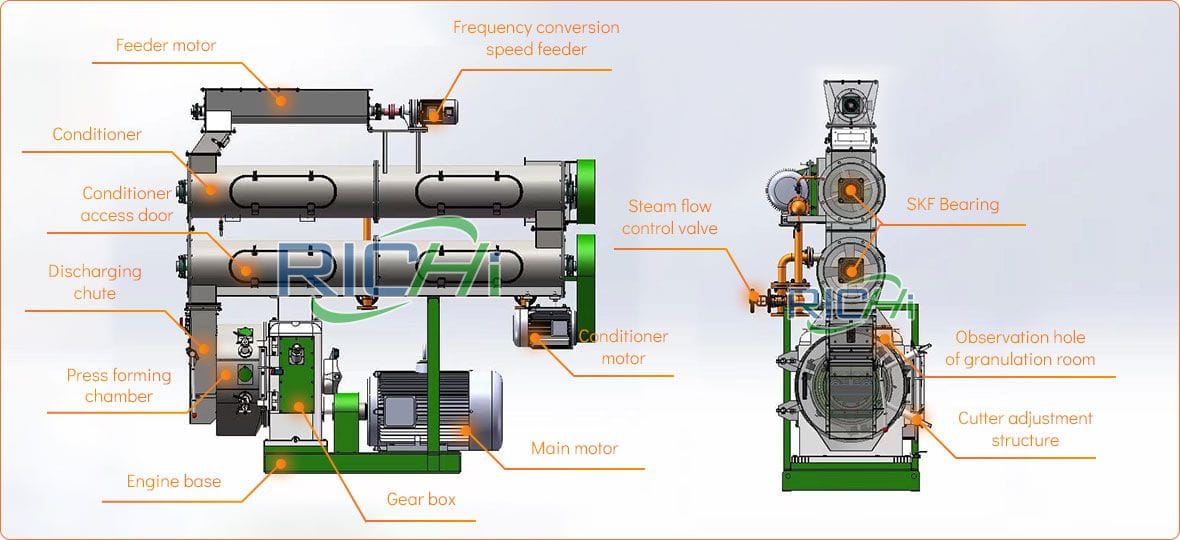

The general sinking fish pelleting mill is mainly composed of a speed-adjusting feeding system, a stirring and tempering system, a granulating system, a transmission system, and a security system. The sunken fish feed pellet machine designed and manufactured by RICHI adopts two-layer or three-layer conditioner.

The ring die compression ratio of sinking fish feed is generally greater than that of livestock and poultry feed, and a high ring die compression ratio is conducive to the stability of the feed in water. In addition, a high compression ratio means a long extrusion time, a large temperature rise of the material, dark color, smooth particles, low powder rate, and low output per unit time.

Features of SZLH250 sinking fish feed pellet mill

- Suitable for producing all kinds of high quality sinking type fish feed.

- Equipped with roller and die distance adjustment device, no need stop pellet mill.

- Use overload protective device and stroke switch to ensure safe operation.

- Cutter mechanism is made of all stainless steel with scale.

- The positioned ring die is easy to load and unload could be equipped with lifting device.

- Use high quality alloy steel ring die which produced by international advanced processing technology.

- Use more thin oil out of pellet mill to cool down lubrication device, lubricate main bearings forcibly.

- Continuous and stable work, very low noise. Stable torque, strong vibration absorption and isolation.

- The transmission parts include motor use high quality SKF bearing, international advanced level power transmitting coupling, international advanced steam valve system, gear with precise abrasive machining and low noise, output raised about 20% more than belt drive.

- The sinking fish feed machine requires the cutter mechanism to be fixed on the box body, which is convenient for observation and positioning, and there is no need to exit the cutter mechanism when opening the door cover; the cutter is close to the outer surface of the ring die to ensure that the ring die can discharge the material at one time.

SZLH250 sinking fish feed pellet mill parameters

| Model | SZLH250 |

|---|---|

| Capacity(TPH) | 0.6-1.2 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

Operating conditions of SZLH250 sinking fish feed pellet mill

- Requirements Before Entering Pellet Machine: 1.0-2.0

- Pellet Diameter (mm): 2-6

- Pellet Length (mm): 4-12

- Ring Die Compression Ratio: 1:16—-1:18

- Conditoning Temperature (℃): 150

- Conditoning Time (s): 90-180

- Equipped Conditioner: two layer/three layer

It is best not to break the aquatic pellet feed. After crushing, the surface of the pellets is rough, which is easy to absorb water and collapse. The small pellets directly pressed have a smooth appearance and are not easily corroded by water, which improves the stability of the pellets in water.

SZLH250 sinking fish feed pellet mill price

Price of sinking fish feed pellet machine SZLH250 Model: 10,000-100,000 USD.

According to your actual needs, you can choose the position of the motor, stainless steel pellet mill machine chamber door can be left-hinged or right hinged to suit the installation, the size of the feed screw, color, etc., and many more are available depending on the machine type. If the customized changes are large, it may cause price fluctuations.

sinking fish feed pellet mill cases

1T/H Sinking Fish Feed Production Plant In Thailand

10T/H Sinking Fish Feed Mill With 4*350T Silos in Algeria

RICHI Service

Quality assurance

- We provide high-quality machines and professional after-sales service. Our goal is to maximize customer satisfaction and value. We usually provide 1 year warranty and free common accessories.

- We promise that our products are brand new and have not been used. They are made of corresponding materials and adopted a new design.

- The quality, specifications, and functions are in compliance with the contract requirements.

Testing

We will take the initiative to test the operation of the machine when it is completed, and take videos to let customers rest assured. When disassembling, we will paste the corresponding label on each part, and provide multi-language installation video and instruction manual. Customer satisfaction is our aim.

Packaging

We will wrap the sinking fish feed pellet mill machine with film to avoid damp and scattered during transportation, and thicken the export wooden box to surround the machine to protect the machine from impact and friction. The size depends on the machine.

Transportation

We can provide multiple channels of transportation. We guarantee that the freight forwarders we use have more than 5 years of cooperation history, provide you with fast timeliness and economic prices, and ensure the safety and integrity of your machines.

Training service

We provide comprehensive and systematic training for technical personnel of each user to better serve customer project needs. After the technicians finish their studies, when they return to the project for operation, RICHI will provide follow-up technical support services, and the trainers will follow up the effect of the project in the later stage to ensure the stable operation of the customer project.

- Equipment structure and principle training

- Fault judgment and troubleshooting training

- Equipment maintenance training

- Equipment operation training

- Introduction training of core components

- Accessories and installation training

- On-site training

- Production process training

Installation and commissioning

After the sinking fish feed pellet mill equipment arrives at the customer’s workshop, please arrange the equipment in accordance with the floor plan drawn up by us. We can use online videos or video tutorials to guide debugging, we can also arrange professional engineers to your aqua feed mill. You need to provide Our engineers’ round-trip air tickets and accommodation.

FAQs about service

1) How about the quality of sinking fish feed pellet mills?

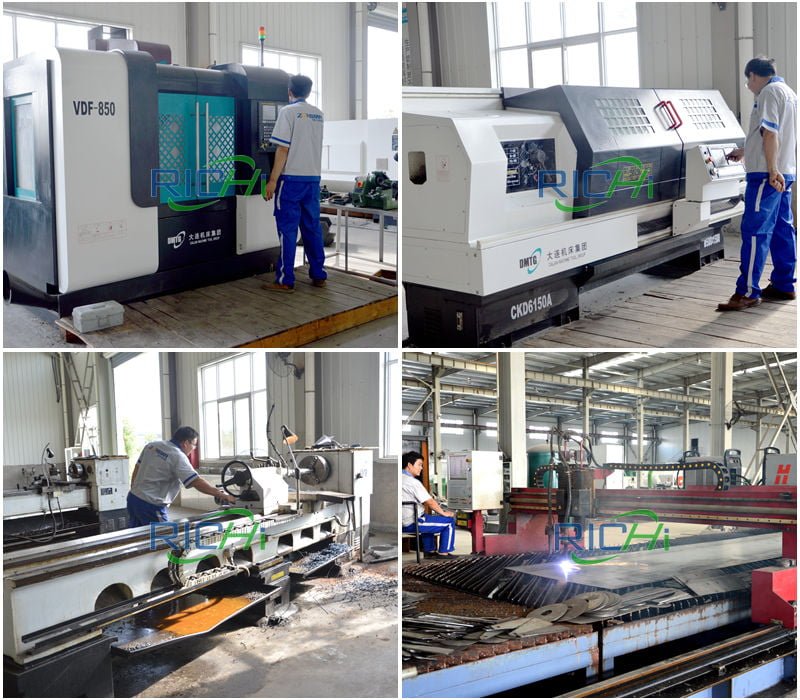

Our machines adopt advanced technology. Moreover, we carry out strict supervision during production and make sure every finished product with high quality.

2) About the delivery time?

Generally, it will be about 20-35 days days after your deposit, which will also be on basis of your order.

3) As for the warranty?

We provide 12 months for warranty.

4) Which kind of payment is available for us?

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash.

5) How about the service?

Provide overseas installation, debugging and training the related work.

6) I know little for sinking fish feed machine and feed production line, what should I do?

Please tell us your requirement, such as what kind of feed you want produce, the output you want per hour, how many raw materials you use, etc., we will send you sinking fish feed pellet machine quotation, if you want to start a complete fish feed plant, we will design the flow diagram for you, and further our engineer will designer the whole sinking fish feed processing line for you depend on your site.

7) Our workers can not know how to operate the fish feed production line, what should I do?

We have installation and after-sale service team, our engineer can go to give customer installation guide. If customer need, our whole engineer team also go to customer’s country.

8) If the sinking fish feed pellet mill has a little problem when produce and can not solve, what should I do?

A: Please contact us immediately, by email, WhatsApp, WeChat, or telephone. Our worker will give you the solution.

FAQs about sinking fish feed production

How to determine the particle size of fish feed?

The diameter of the pellet feed must match the size of the caliber of the cultured fish, so that it is beneficial for the fish to eat. If the diameter is too large, it is difficult for fish to swallow, and the feed can only be eaten after it is soaked soft, which not only increases the loss of water-soluble feed components, but also causes water pollution; if the particle size is too small, fish must feed for many times In order to meet the needs, because the feeding time is prolonged, it will not only increase the waste of feed, but also increase the consumption of energy.

For pellet feed with too small particle size, it is necessary to consider reducing energy consumption in the production process and also consider the constraints of processing technology. Therefore, crumbled feed can be used. That is to say, after the large pellet feed is crumbled, it is sieved into many crumbs or coarse chips of different sizes by standards of different sizes, so as to meet the different needs of raising various sizes of young, immature, juvenile, and adult fish.

The pellet length is generally 1.5 to 2.0 times the particle diameter. Different cultured species of fish have different requirements for the particle size of pellet feed at different development and growth stages.

Working principle of fish feed pellet machine

RICHI sinking feed pellet mill adopts multi-stage tempering technology. Multi-stage conditioning improves the conditioning effect by prolonging the conditioning time, and the degree of starch gelatinization can reach 40% to 60%.

After granulation, curing and tempering is to keep the freshly pressed granules (about 80-85℃) warm, and let the hot granules last for a certain period of time in a high-temperature and high-humidity environment, so that the starch in the granulated feed is fully gelatinized and the protein is fully denatured. . At the same time, the cracks generated in the early stage are pasted again to improve the durability of the feed to meet the special requirements of aquatic feed.

The most important and vulnerable part of the sinking fish feed pellet mill is the ring die. The ring die is driven by a motor to rotate. There are 2 built-in pressure rollers. The pressure rollers do not revolve. The rotation of the ring die causes friction with the material to form a rotation. During the relative movement with the pressure roller, according to the force difference, the ring die forms 4 areas:

- ① In the feeding area, the material is loose and attached to the inner ring of the ring die by centrifugal force;

- ②In the compaction area, the material is squeezed by the roller, the powder particles move relative to each other, and the gap decreases;

- ③In the extrusion zone, the material undergoes plastic and elastic deformation, and the powder particles are connected, compressed to ≈1.3g/cm³;

- ④In the forming area, the material fills the die hole and becomes columnar, and the friction heats up. The frictional temperature rise of the pressing roller reaches about 100 ℃, and the temperature of the material rises for a short time under the friction force and shear force, which is 5-10 ℃ higher than that after conditioning.

Core technology of fish feed pellet machine – multi-stage tempering

This conditioning method is developed on the basis of ordinary conditioning, mainly to improve the conditioning effect by prolonging the conditioning time under the condition of maintaining a certain amount of moisture.

That is, two or three double-jacketed conditioners are used in an orderly combination to prolong the conditioning time of the powder in the conditioner. At the same time, steam is introduced into the jacket to heat the powder, increasing the temperature of the powder, increasing the starch gelatinization rate and protein denaturation degree of the powder, and strengthening the cohesive force inside the granules. This not only improves the stability of the pellets in water, but also improves the digestibility of the feed. Most aqua feed mills use this method.

But as far as each set of equipment of each specific sinking fish feed pellet mill manufacturer is concerned, they each have their own particularities. For conditioner angle, almost every conditioner is installed horizontally. Add a device behind the conditioner that can raise the conditioner, and use flexible feeding and discharge ports to achieve almost arbitrary adjustment of the residence time.

Under normal operating conditions, conditioning begins with the conditioner installed horizontally. Once stable operating conditions are obtained, the conditioner can be tilted to extend the residence time to the desired level.

As for the angle adjustment of the paddle, the front 1/3 of the paddle is at an angle of 45 degrees to the shaft, and the rear 2/3 of the paddle is properly adjusted. During the residence time in the tempering chamber, the The material in the rear section of the conditioning chamber can be adjusted arbitrarily.

Long-term tempering generally adopts the method of increasing the tempering time to achieve the purpose of strengthening the tempering. With the continuous improvement of feed quality requirements and the rapid development of special aquaculture, conditioning methods such as multi-stage conditioning, aging conditioning after granulation, and high-pressure ring gap expansion conditioning have emerged.

If you are interested in our SZLH250 sinking fish feed pellet mill, or you want to build your sink fish feed plant, you can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time!